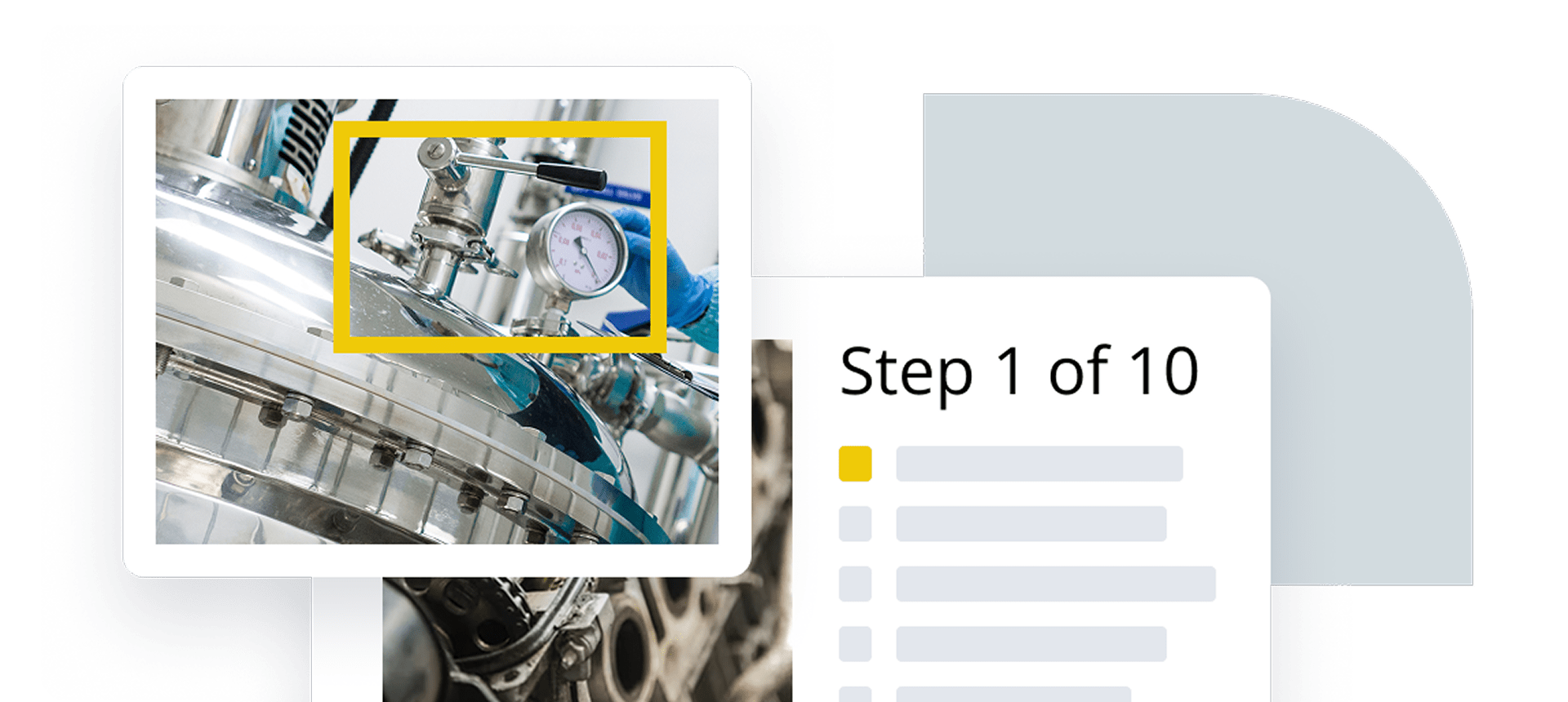

Enable your frontline workers with the knowledge and support to perform safely and to standards. Easily capture and centralize the knowledge of experts, making it easy to share across shifts and locations.

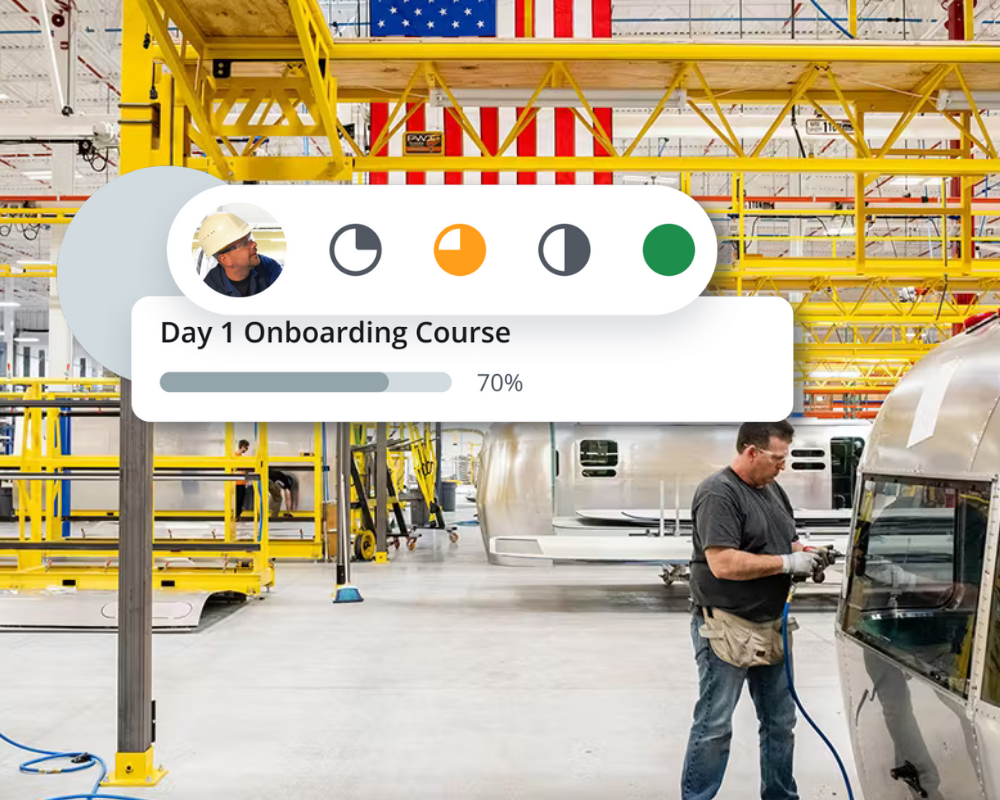

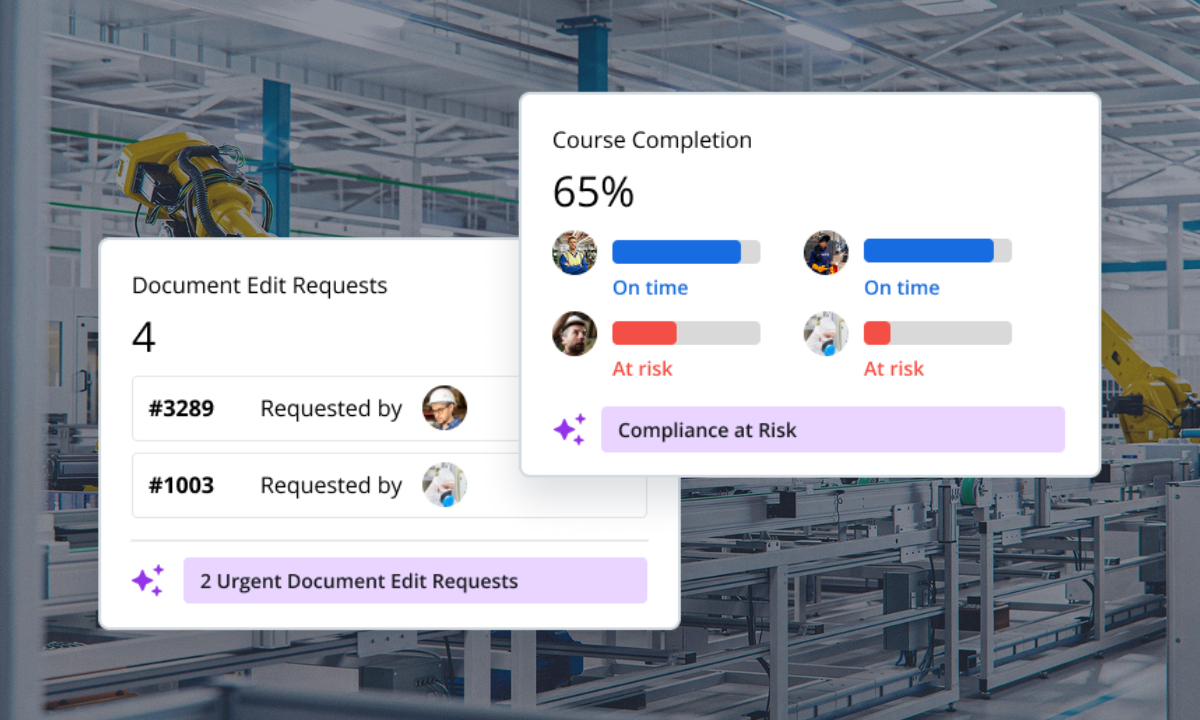

Turn documented standards into training programs to fill skills gaps. Eliminate job shadowing by distributing standardized guidance across production lines, departments, and facilities.

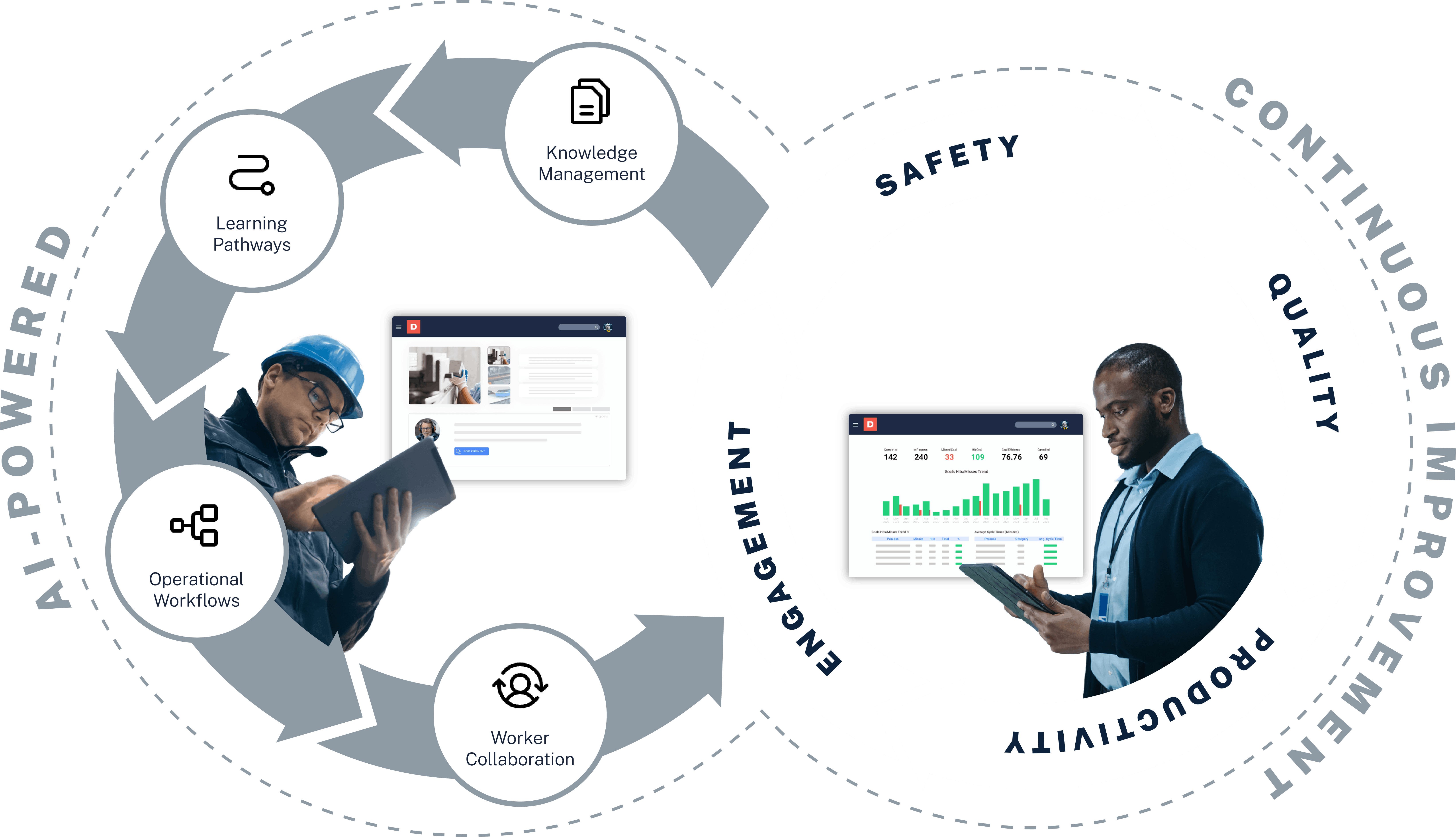

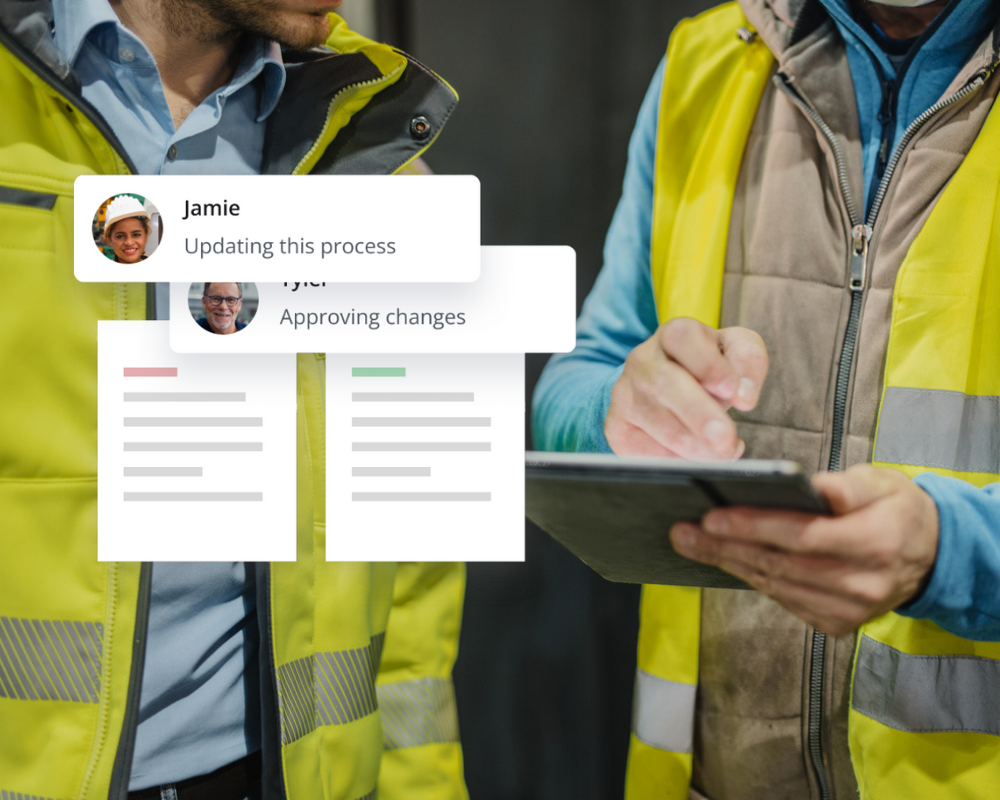

Continuous improvement is driven by workers providing feedback on instructions, with authors following up to improve documentation, and changes communicated back to workers.

Our services team and partners offset your limited internal resources, providing extensive guidance throughout implementation and advanced rollouts.

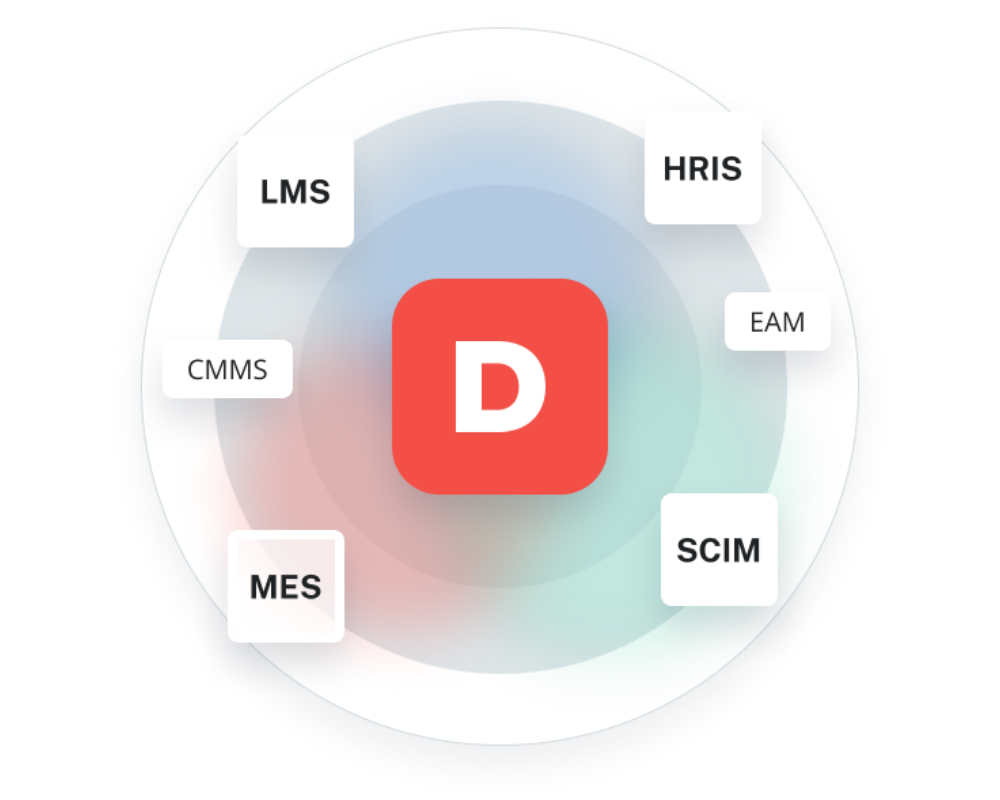

Connect Dozuki to digital manufacturing ecosystems to bridge the frontline gap in digital workflows and data visibility. Using our integration experts, customers extend the power and value of existing systems by giving you unprecedented visibility into frontline data to drive operational excellence across frontline teams.

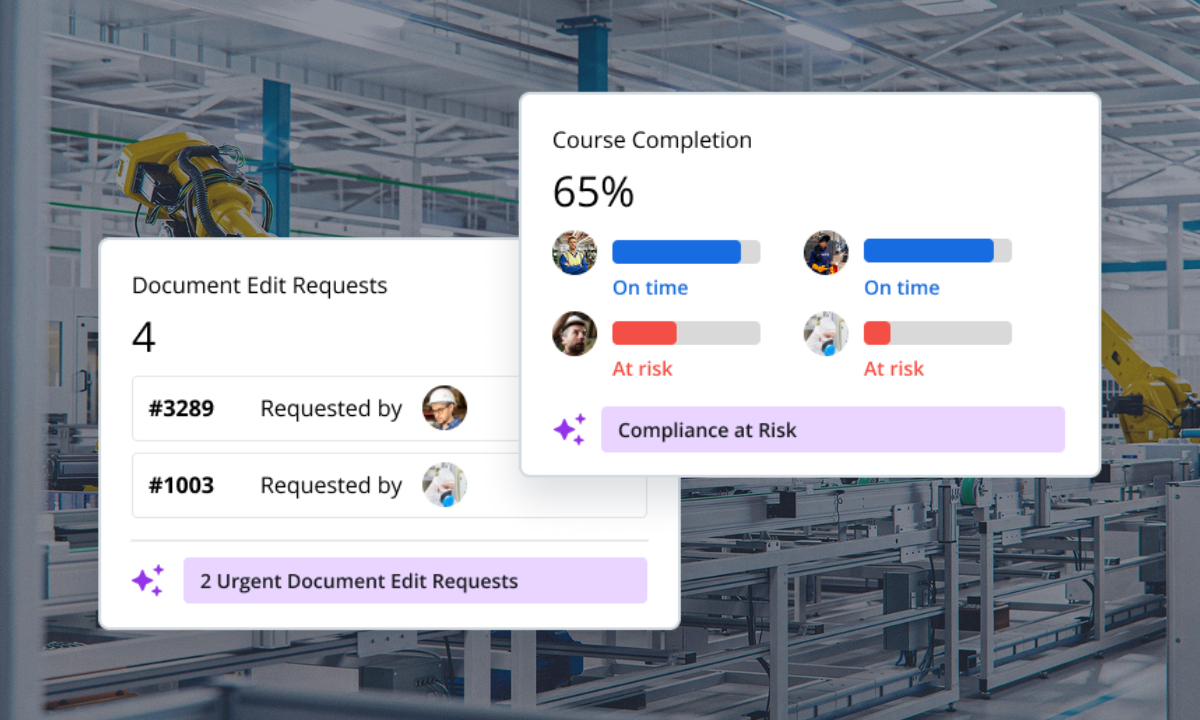

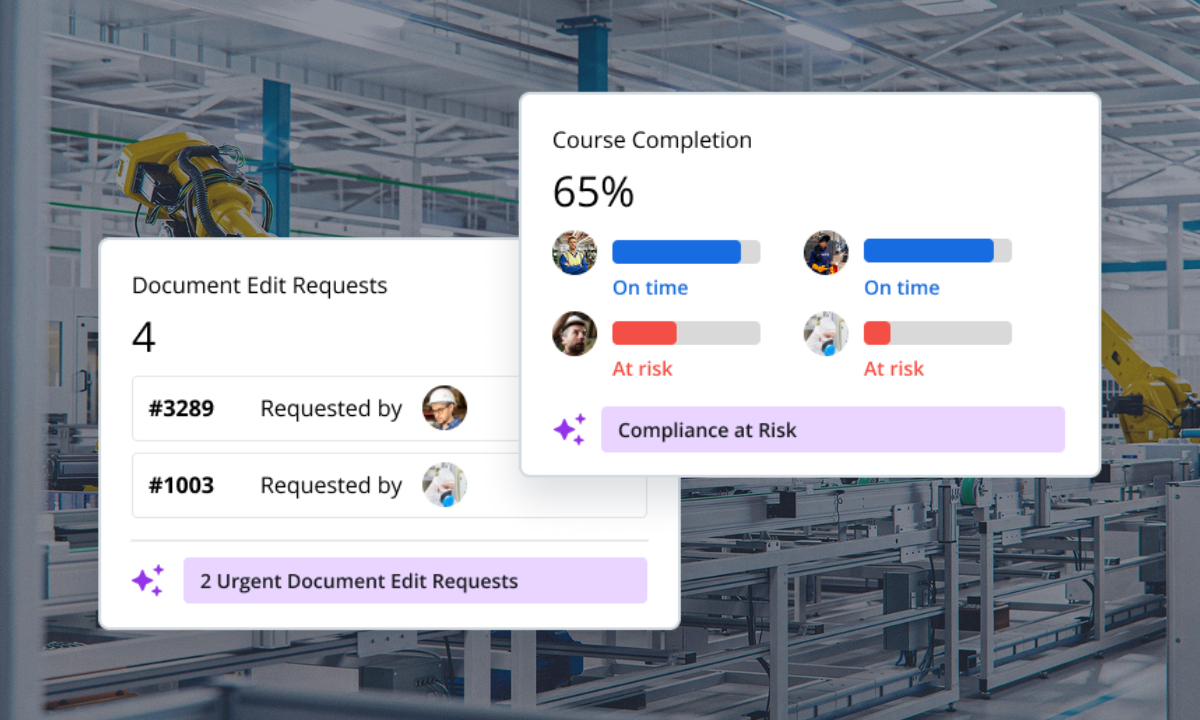

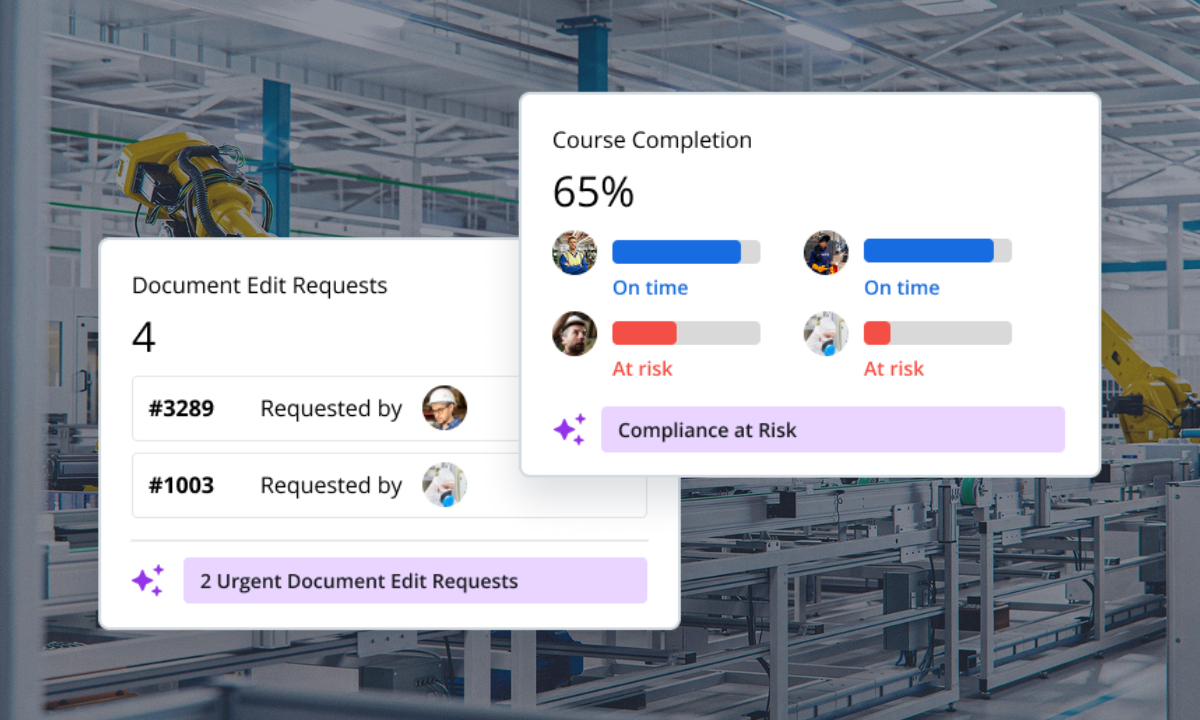

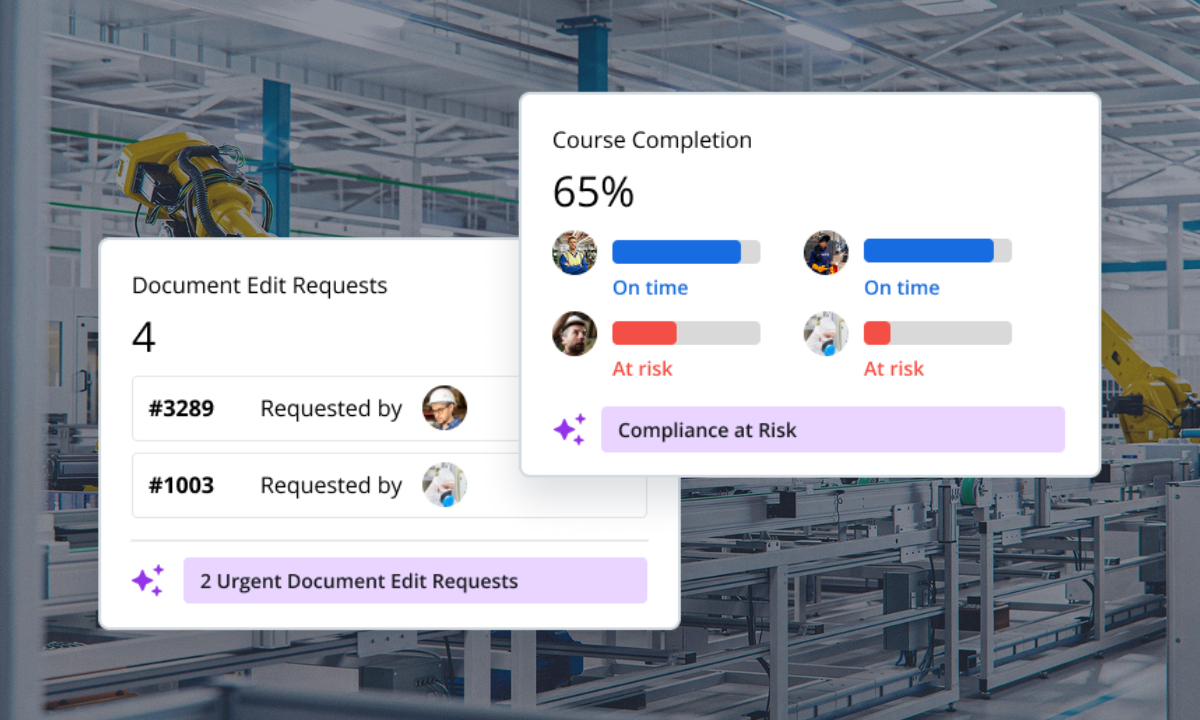

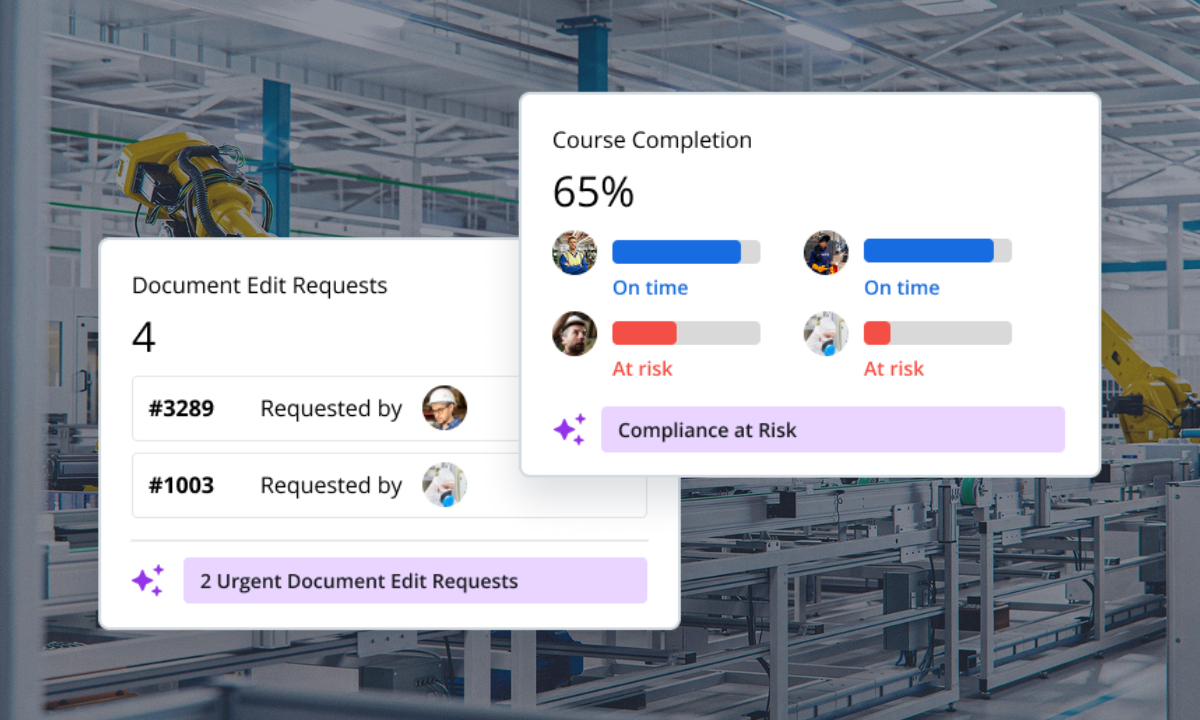

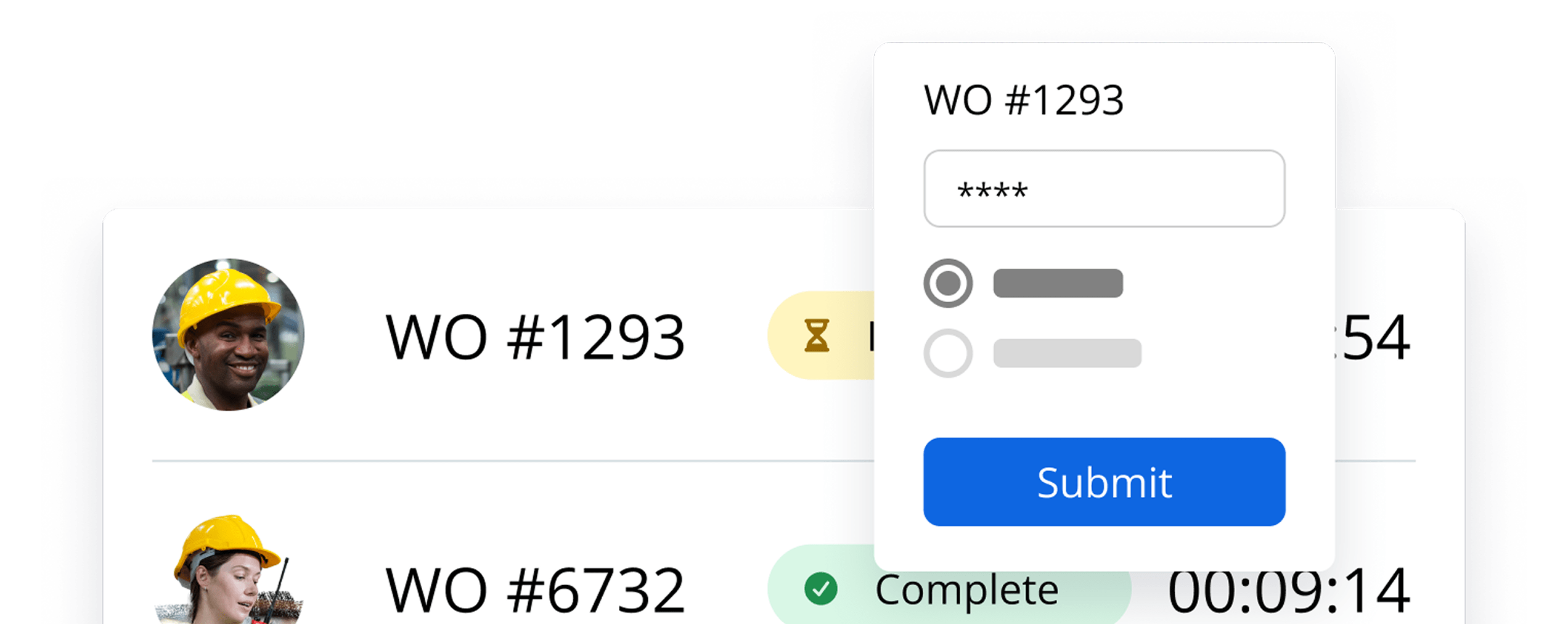

The ultimate audit trail for people and products. Track process changes, approvals, training completions, and work orders against the latest standards for complete compliance visibility.

Track changes, approvals, and content performance. Analyze how procedures evolve over time and monitor approval timelines. Gain visibility into who made changes, who authorized them, and how these updates impact your team’s access to critical knowledge.

Turn worker feedback into actionable insights. Monitor worker feedback trends, implement process improvements, and reward engagement, driving continuous improvement at the front line.

Get insights into your operational knowledge management. Track standard work procedures, revisions, releases, and visibility metrics. Ensure teams are fully aligned with your latest operational standards.

Comprehensive training and skills visibility across the workforce. See who is trained on what, the current version they’ve certified on, and identify skill gaps to ensure your workforce is always ready and capable.

Unlock process optimization insights across operations. Analyze data captured during procedures and checklists, including sign-offs, measurements, and media, to improve safety, quality, and production efficiency.

“We’ve captured 100+ improvements directly from the floor using Dozuki.”

“Dozuki cut our training time by 75%. It’s the foundation we’re building everything on.”

“Before Dozuki, 30% of new hires were leaving. Now it’s down to 5%.”

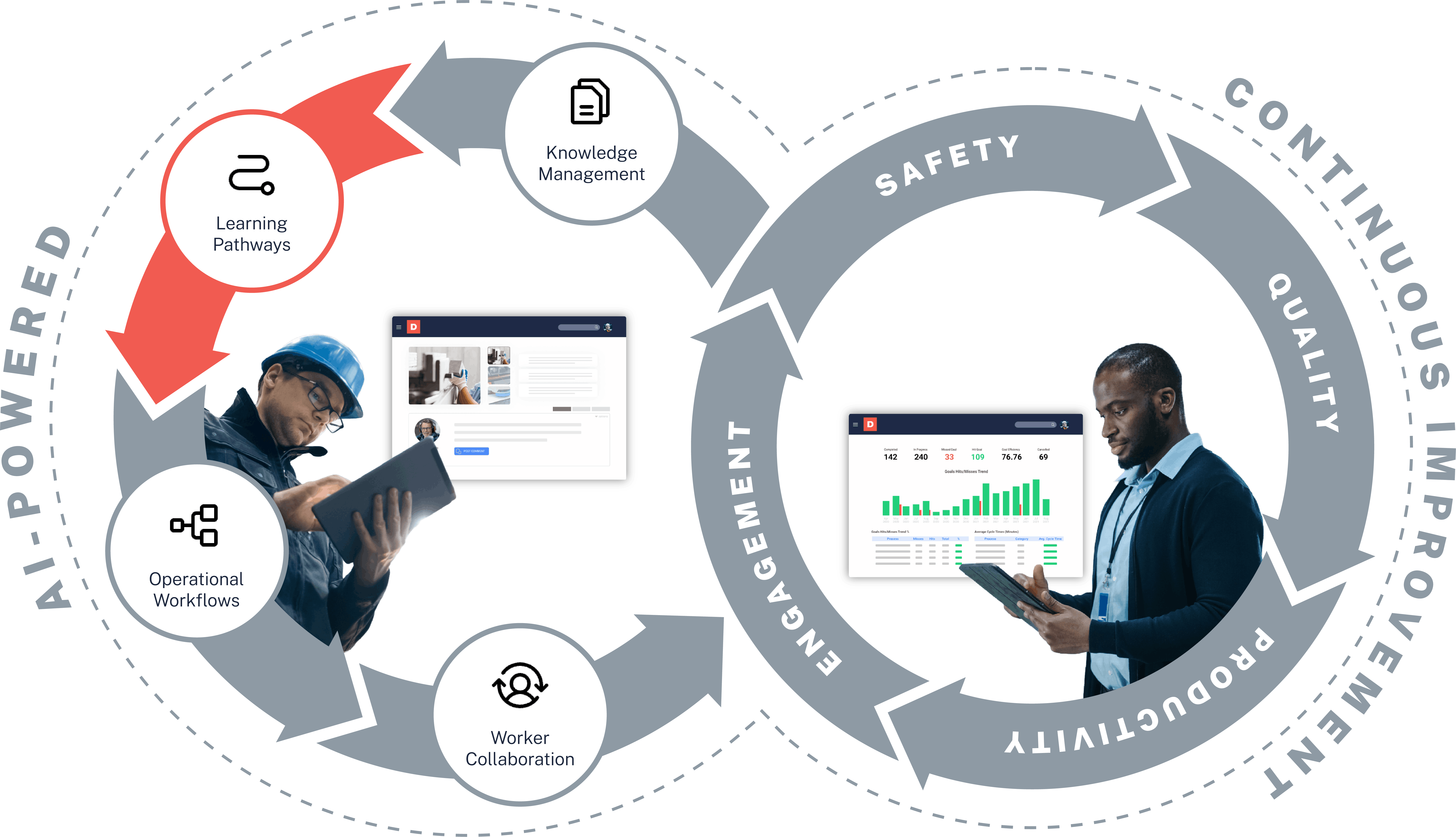

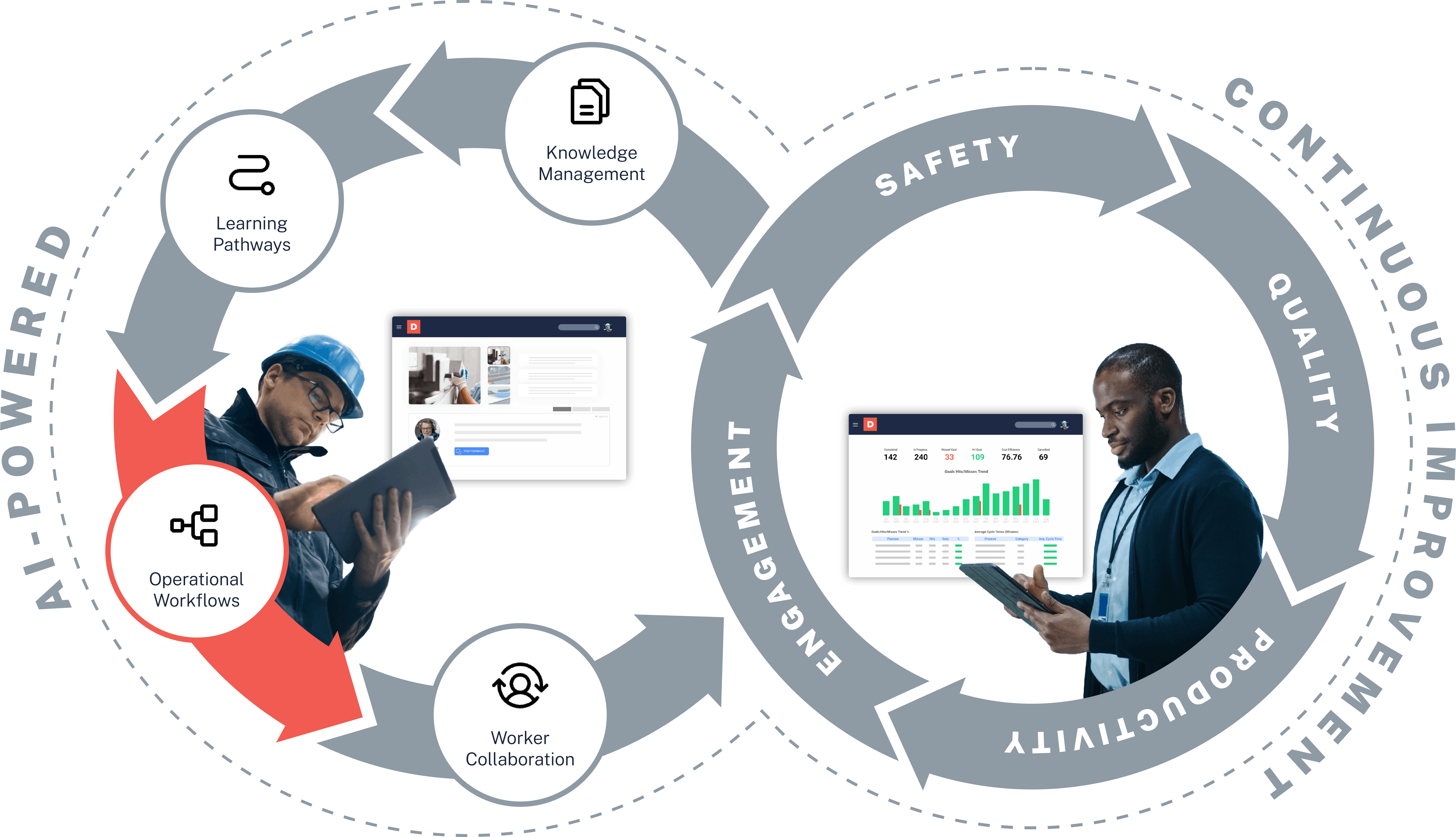

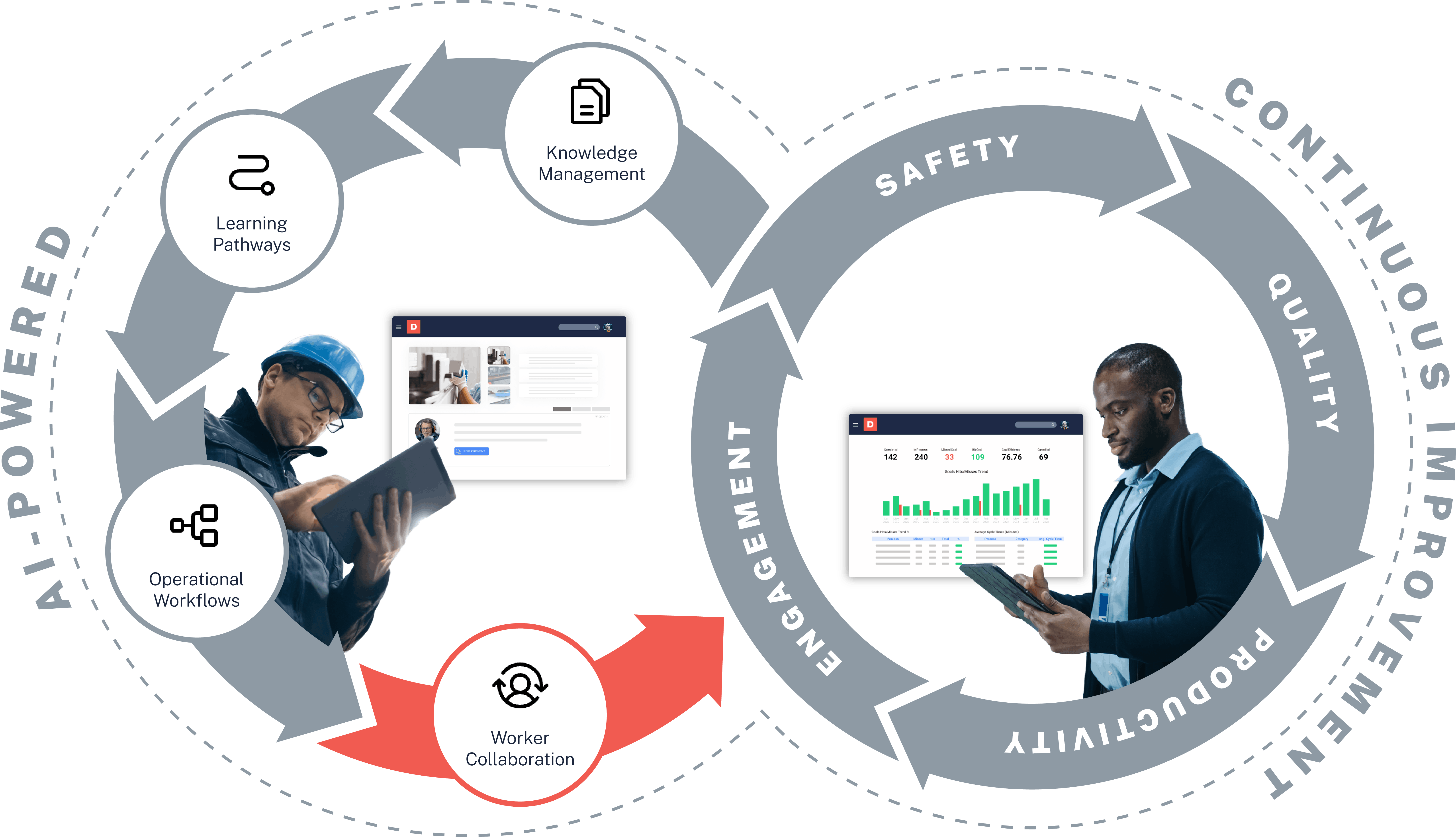

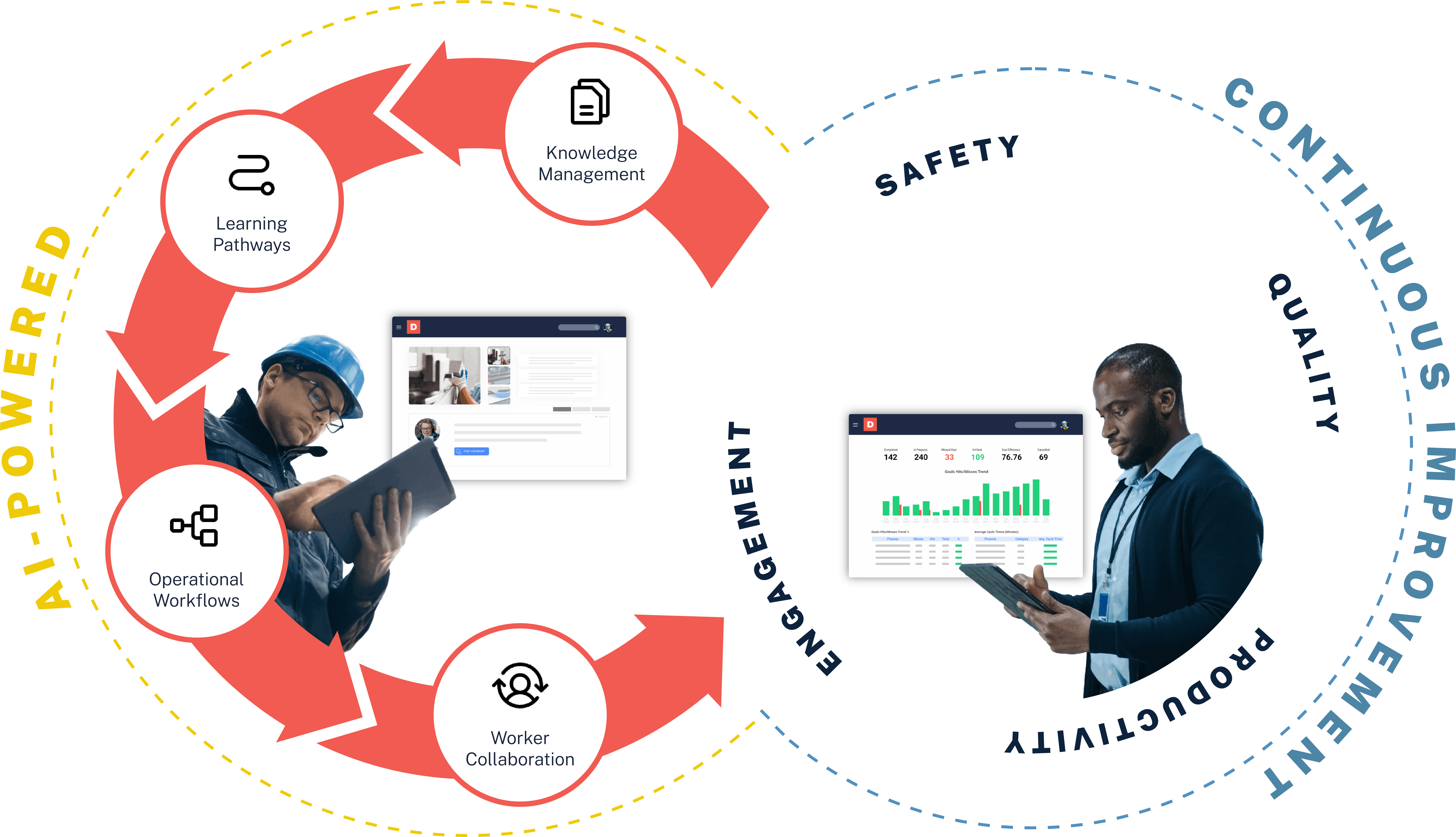

Companies need a modern way to capture knowledge, scale training, and ensure standards are followed across every site and shift.

What is a Connected Worker Platform?

A Connected Worker Platform enables frontline employees to access, execute, and improve operational knowledge in real time. It connects people, processes, and systems to drive consistency, agility, and measurable performance.

How is this different from an LMS or MES?

Unlike LMS or MES tools, a Connected Worker Platform focuses on day-to-day execution, training, and collaboration at the human level. It integrates with these systems, but fills the critical gap between high-level planning and hands-on work.

What problems does it solve?

It addresses workforce turnover, skills gaps, process variability, compliance risk, and operational inefficiencies, helping teams standardize knowledge, accelerate onboarding, and sustain continuous improvement.

How does Dozuki support integration?

Dozuki connects with your LMS, MES, HRIS, and more through native integrations, APIs, and SCIM. This ensures seamless data flow and centralized visibility without disrupting your existing systems.

How fast can we get started?

With AI-powered tools and Digital Transformation Services, companies typically begin seeing value in weeks, not months. Our team helps accelerate deployments while minimizing internal disruption.