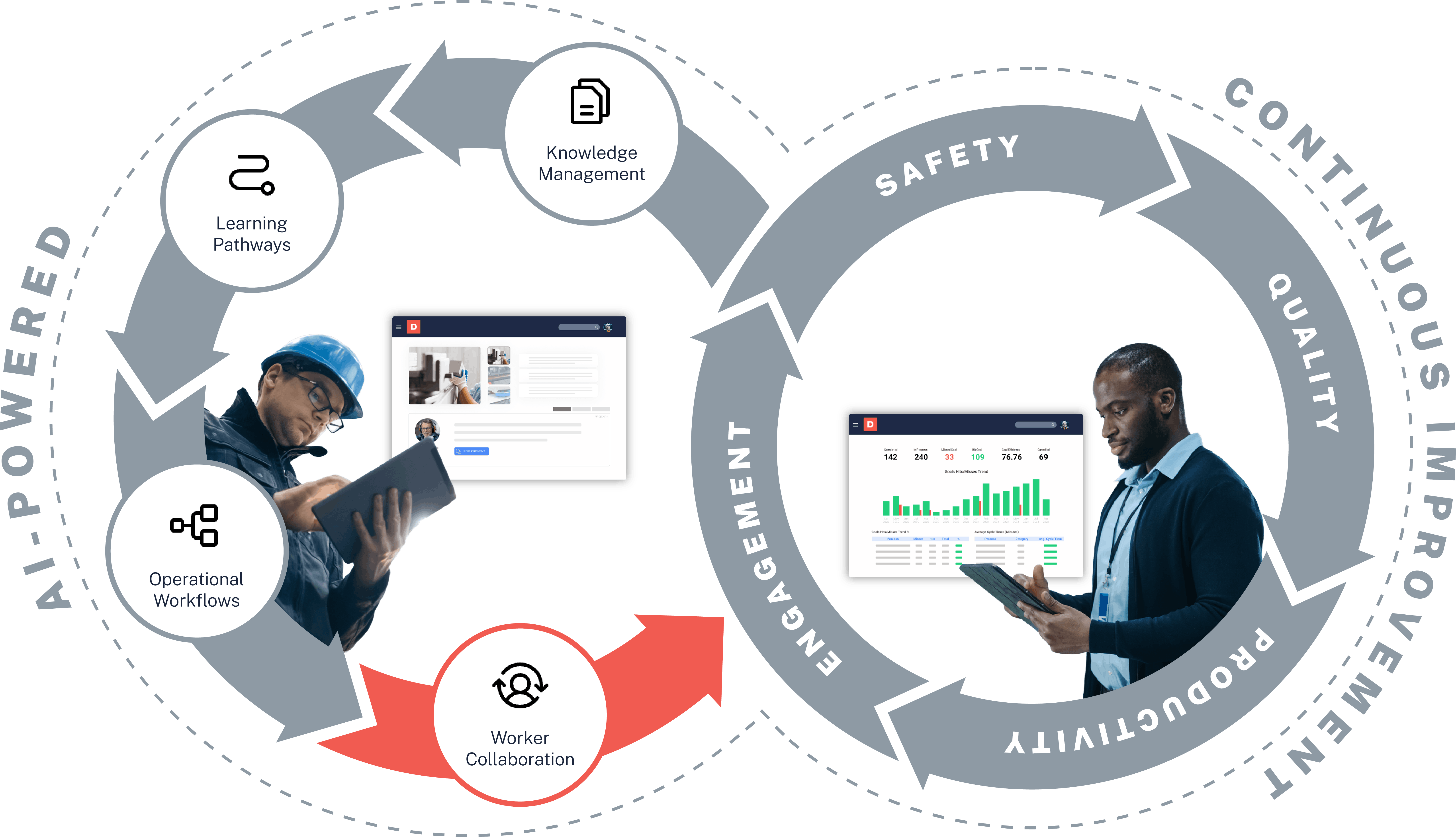

Dozuki enables worker-led feedback, seamless change communication, and collaborative problem-solving — ensuring frontline employees have a voice in improving processes and driving operational excellence.

Close the loop between worker feedback and action by turning inline comments into trackable improvements in Dozuki. Continuous improvement gets baked into the culture and part of the daily operating system.

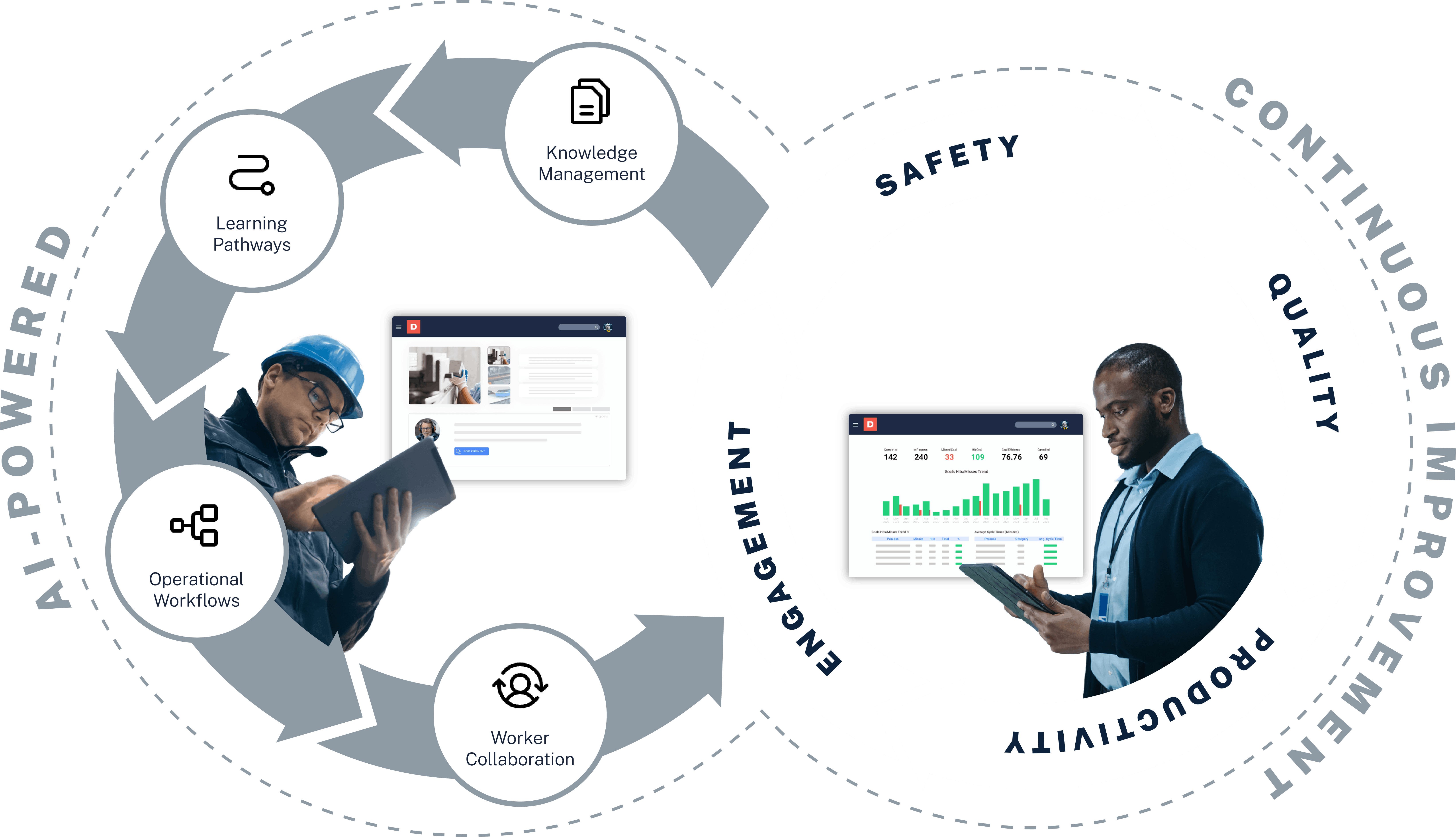

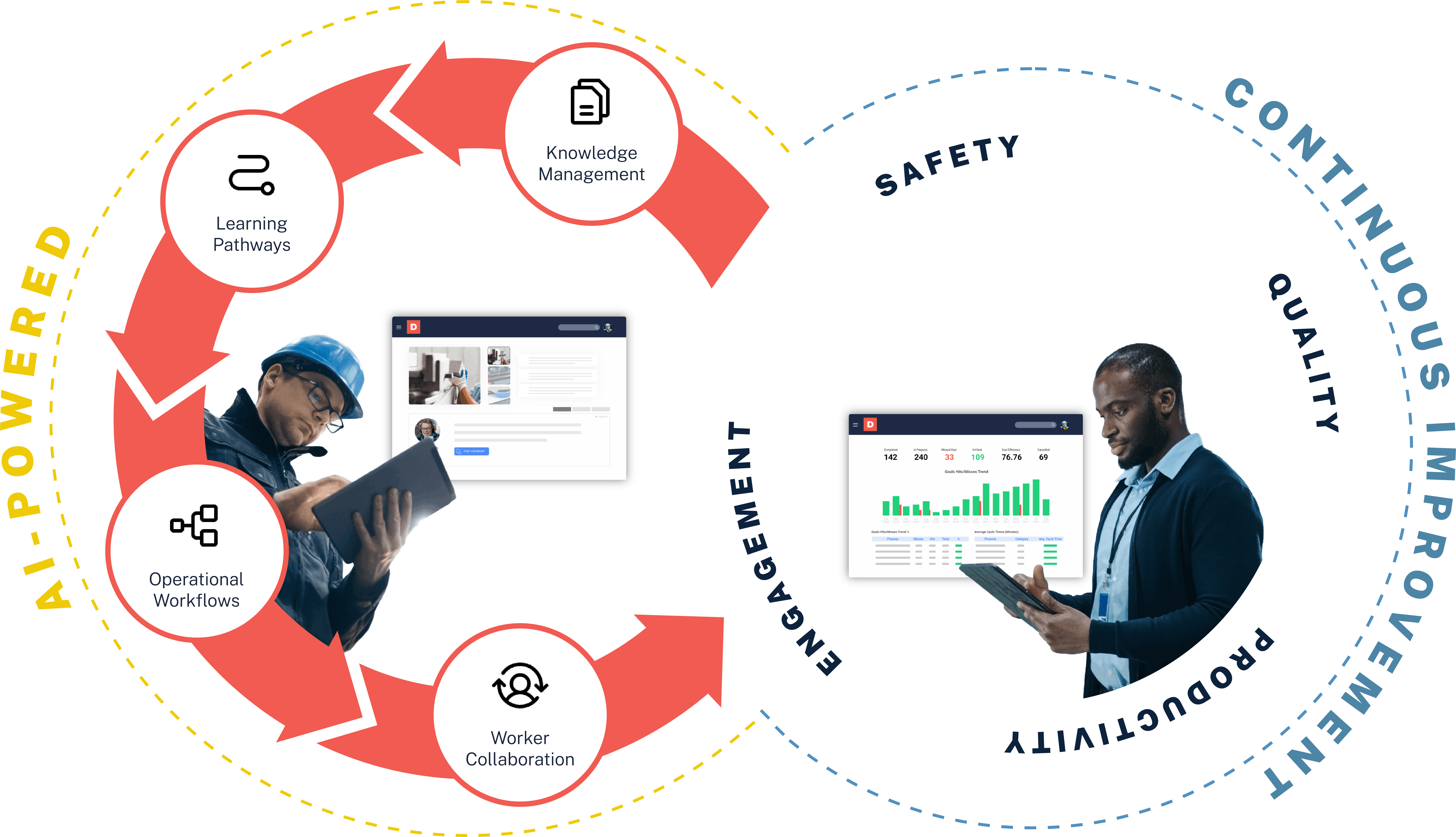

Build engagement on the across your workforce by capturing frontline insights at the point of work. With real-time feedback, structured approvals, and built-in retraining, Dozuki transforms daily operations into a dynamic engine for quality, efficiency, and innovation.

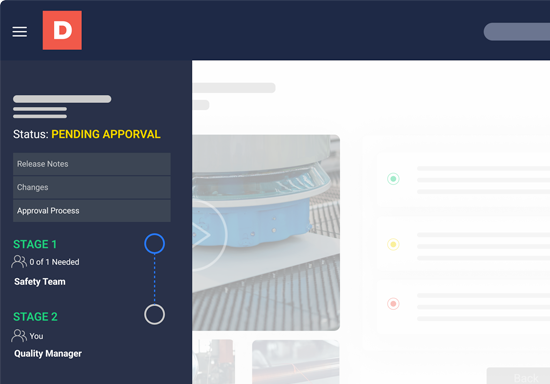

Ensure faster approval processes that natively fold in frontline feedback to keep operations moving smoothly and embedding continuous improvement into daily work.

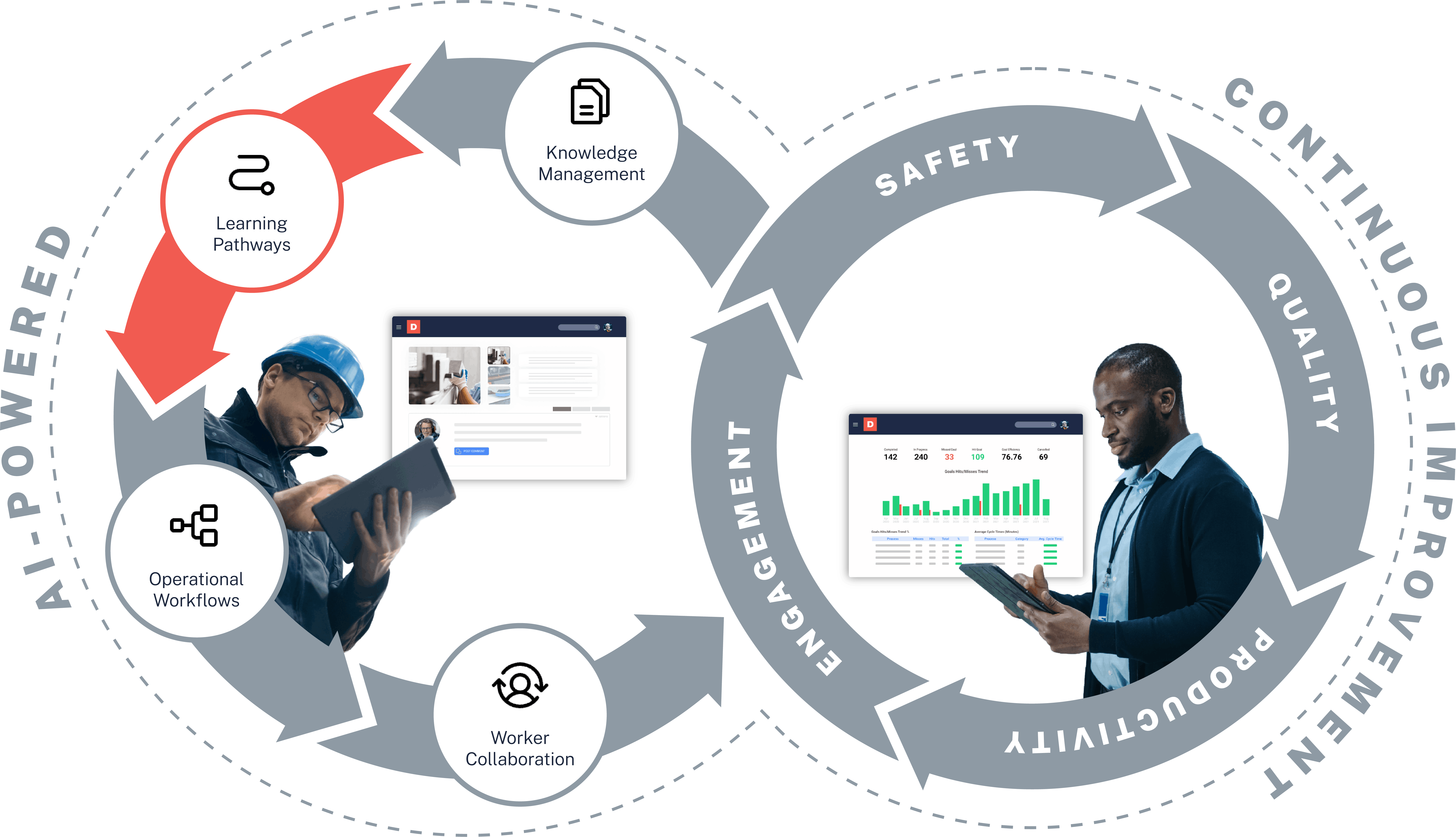

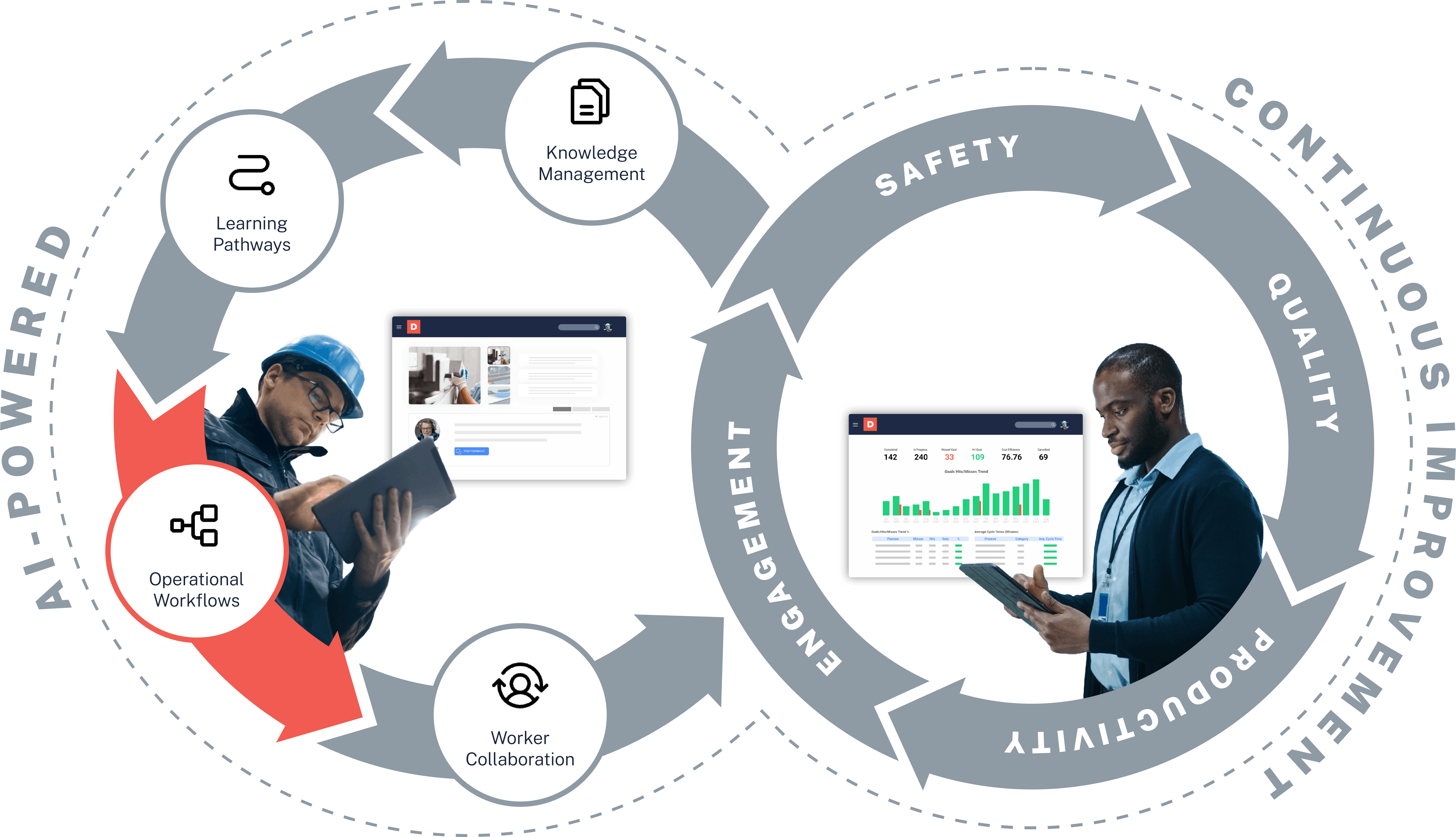

Fold continuous improvement gains into everyday operations by surfacing insights and critical updates to workers where they need it. This transformative approach to the connected workforce brings your operations into Industry 5.0.

Workers are overwhelmed by fragmented systems and constant context switching with tasks, training, and issues scattered across silos. Dozuki brings it all together, surfacing the most relevant, actionable items so workers can stay focused and productive.

Unlock frontline knowledge, improve execution, and build a culture of ownership.

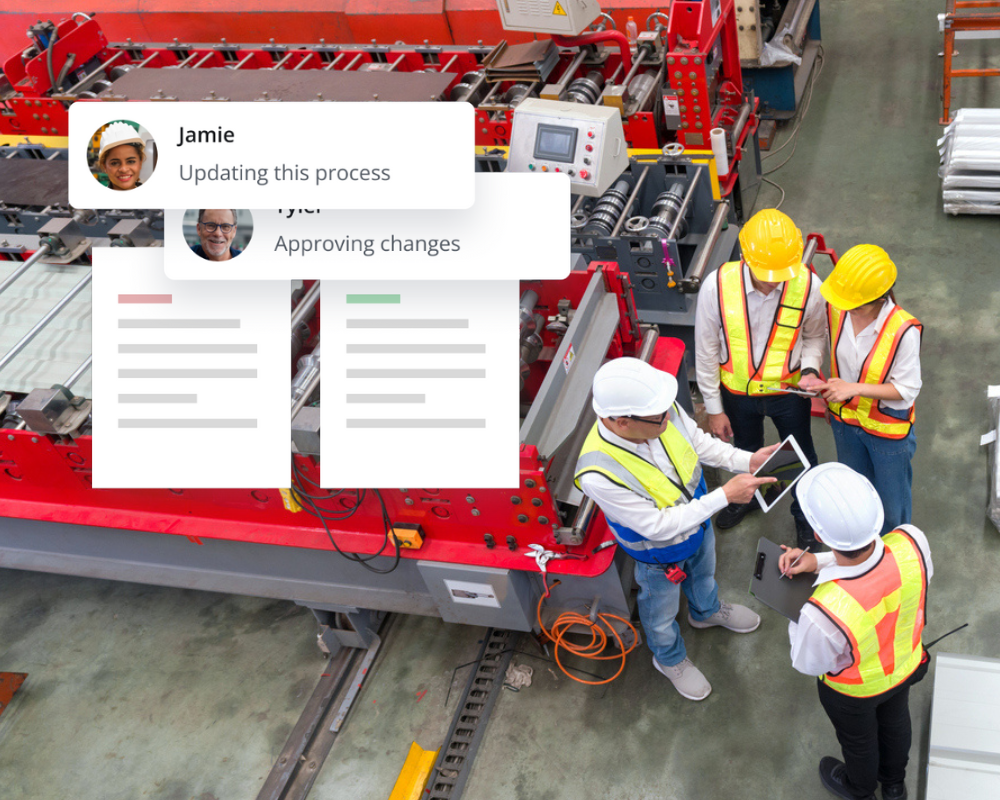

Frontline workers know the job better than anyone. Dozuki gives them a simple way to share observations and ideas for improvement in the moment, when the insight is freshest.

Whether it’s during an audit, a quality check, or everyday task execution, workers can document suggestions directly within their workflow. This makes continuous improvement part of daily operations.

Insights are only valuable if someone acts on them. Dozuki routes submitted feedback to the right teams for review, tracking resolution status and accountability at every step.

With visibility into topic, urgency, and source, your teams can triage feedback effectively and demonstrate that worker contributions are seen, considered, and acted on.

When feedback leads to change, it’s critical to formalize it. Dozuki makes it easy to update the standard, involve the right reviewers, and communicate those changes to everyone impacted.

Changes flow directly into updated procedures. Retraining is triggered automatically so improvements don’t get lost in email threads or paper updates.

When workers see their ideas implemented, they feel a stronger sense of pride and ownership in their work. Dozuki helps build that culture by making change visible and repeatable.

Contributors are recognized, feedback is looped back to the team, and engagement becomes part of the performance equation.

Unaddressed issues put performance at risk. Dozuki gives workers a structured, in-the-moment way to flag defects, safety hazards, or bottlenecks without disrupting the task at hand.

From photos and step notes to checklist failures, issues are captured with precision and routed for resolution so you are not waiting until it’s too late to act.

Knox Company transformed their process documentation with Dozuki, empowering frontline employees to participate in updates and continuous improvement. What once required weeks of back-and-forth between teams now happens in hours, with shared ownership, clear accountability, and streamlined approvals.

The platform created a direct line between engineers and operators, turning isolated tasks into collaborative wins. By involving workers in standard updates and feedback loops, Knox saved over 2,500 hours and built a more connected, improvement-driven culture.

“Training is now continuously updated, based on worker feedback and insights.”

“Operators find answers 55% faster, right at the machine.”

“Dozuki helped reduce our workforce turnover by 83%.”