The ultimate guide of strategies and analyses for facing the challenge of engaging a younger workforce for manufacturing companies amidst a shifting labor market.

The next generation of American factory workers have their work cut out for them.

With trends showing a rapid increase in the number of baby boomers retiring from the industry, there exists a widening opportunity for new talent to enter the field. But, over the next decade roughly 2 million manufacturing jobs in the U.S. are still expected to remain unfilled.1

This resource gives manufacturing companies insights into attracting and retaining younger talent to help fill these critical open roles.

Surely if there are available jobs, unemployed Americans have an interest in filling them.

Not so fast.

If you were to play a word association game with the average American, ‘manufacturing’ might produce connotations like the industrial revolution, the automotive industry, Henry Ford, etc. What you won’t likely hear, are topics like nanotechnology, advanced materials, or artificial intelligence — all ranked as the most important future technologies by industry executives. Which goes to show how disparate the perception and reality of the industry are.

In fact, the United State’s overall interest in manufacturing has decreased over 70% since 2004, according to latest Google Trend analytics.

The world of manufacturing has evolved at a rapid pace over the decades, but many Americans are unaware of its strides.

With such a decline in public interest, it’s no wonder that companies are having trouble filling open positions. What does this mean for the industry as a whole? In short, it means that there will be millions of new manufacturing jobs, with not enough interested or qualified people to fill them.

The complexity of manufacturing jobs has been growing swiftly, but the industry’s ability to recruit and train the required workforce has not kept pace.

The increased skill levels, specializations, and types of tasks required on the shop floor have transformed the notion of what it means to be a factory worker. Assembly line workers have become repair technicians. Quality supervisors have become data analysts. Those who used to screw on bolts, now manage automation processes.

In order to save domestic manufacturing from itself and help bridge this growing skills gap, the industry needs to actively change its approach to attracting and training workers in this evolving landscape.

The next generation of manufacturers will be met with a more technical and data-driven work environment, one that will value traits like technical literacy and critical thinking, over hard skills.

A historically static industry is facing new and dynamic terrain that presents a unique (but solvable) set of challenges.

This might be the biggest problem facing the manufacturing industry to date. It’s not a lack of qualified people, it’s getting those qualified candidates to apply in the first place.

In a recent study, millennials (ages 19-33 years) ranked manufacturing as their least preferred career destination. Because of an outdated perception, this new workforce is reluctant to fill good positions in the industry.6

Unfortunately, the old views of manufacturing aren’t particularly glamorous. Facilities in past generations were often dirty, smoke-filled, and potentially dangerous environments. While the industry is much more high tech these days, most people still conjure up images of greasy steelworkers and coal miners when they think of the manufacturing industry as a whole.

In reality, most modern manufacturing jobs are for skilled production workers in roles such as technicians, data analysts, operators, or machinists. The fastest growing jobs in the industry continue to be process control, programming, and maintenance of sophisticated machinery.

It’s on manufacturers to actively change these outdated perceptions of the industry in order to attract more qualified candidates.

The average age of the manufacturing workforce is rising, but not for long. As the baby boomer generation (ages 51-69) begins to retire, younger workers will have to take their place. Because of declines in domestic manufacturing, productivity gains, and a weak economy, hiring has remained relatively flat over the last two decades.

As a result, many existing employees are nearing retirement, with no replacements in their wake. This, in conjunction with increasing job availability, will soon cause a sharp decline in the average age of the the manufacturing workforce. In fact, across all industries in the U.S., millennials have already taken hold as the dominant labor force.

Particularly relevant to the industry is the compounding disparity between the age of the workforce. A declining number of baby boomers combined with a rising number of millennial workers, will lead to a swift decline in the average age of employees. Not only will this create an immediate need to train a large number of new employees, but manufacturers will have to change the way in which they train this evolving workforce.

Due to high retirement rates, the traditional ways of passing down knowledge via 1-on-1 training will no longer be viable. There simply won’t be enough senior employees to train and mentor new hires, therefore, manufacturers will have to rely on more efficient long-term methods to train people.

6 out of 10 positions (60%) remain unfilled due to the talent shortage.2

The average U.S. manufacturer is losing an estimated 11% of its annual earnings (EBITDA), or $3,000 per existing employee, due to the talent shortage.3

In the next ten years, nearly 3.5 million manufacturing jobs will need to be filled.4

The skills gap for these new manufacturing jobs is expected to result in two million of those jobs going unfilled.5

Millennials have drastically different workplace expectations than the generations before them. 87% of millennials say professional development or career growth opportunities are their highest priorities when evaluating a new job.7

To them, waiting 20 years for a supervisor to retire in order to get promoted is not an appealing career path.

It’s important to consider the impact that this new generation’s expectations and learning styles will have on the way the industry hires and trains employees. Professional development means providing opportunities for your workers to continuously grow and expand their skillsets, beyond their current roles.

One advantage this younger workforce has is their innate confidence with technology and software. Millennials are “digital natives,” meaning they are naturally more adept when it comes to using and operating digital tools. With screens attached to every machine and the advancement of digital tools, technical competence will become far more valuable than one particular set of hard-skills.

In a study done by Deloitte, manufacturing executives indicated that there is an increasing skill gap, where 70% of current employees fall short of the basic technical skills needed to thrive in their current work environment.8 Basic technical skills are also known as technical literacy, a well-rounded set of abilities that result in an overall technical competence or “know-how.” Digital savvy employees provide an opportunity for manufacturers to achieve a new advantage, and allow millennials to thrive in the new tech-focused environments of the industry.

The flip side of this advantage is that a text heavy 3-inch binder full of static information, will no longer be a sufficient enough to engage, train, and motivate younger employees.

Millennials are accustomed to educational material that uses mixed forms of media and digital interaction to inform and learn. This is a good thing. Visuals and other forms of communication will increase understanding and retention rates. In fact, studies show that 65% of the population learns better when visuals are used to supplement information.9

These days, technicians and operators aren’t just on the assembly line. In fact, these types of positions have nearly fallen by the wayside, with advanced technical jobs being the new norm. This is great for many reasons.

We’ve let machines automate the things that humans aren’t good at (repetitive tasks) and turned our efforts to the things that require our cognition, like process control and complex problem solving.

Due to the increasingly technical and complex nature of jobs in domestic manufacturing, the efficacy of training materials will have a huge impact on operational efficiency. Not only do technical jobs require in-depth training, but they also require regular process refinement and optimization.

Not only will this affect those being trained, but it will also have a significant impact on document creation efforts. With a larger variety of procedures needed to be documented, optimizing the authoring process will be essential to plant efficiency and productivity.

Unlike previous generations, millennials seek more from their jobs than just a stable income, often prioritizing flexibility and recognition above money.10 If we really want to look at larger societal trends, comparing the baby boomers to millennials, it’s also important to consider the work/life balance that millennials want from their employers.

This generation gets their value from feeling part of something important, and feeling like their voice is heard. They resent the idea of being just another “cog in a machine.”

The challenges of training the next generations of manufacturers is a blessing in disguise. Sure, employing millions of new millennials has its set of obstacles. But there’s a silver lining.

In the past, the manufacturing sector has be the slow to utilize emerging technologies, making the industry particularly resistant to operational innovation.

After studying over 400 firms over a period of two years, MIT Sloan found that only 25% of industry executives believed that they would be impacted by digital transformation.11

The quickly shifting landscape will force many manufacturers to adapt. The silver lining is the massive opportunity that companies are now presented with.

From virtual reality (VR) environments to artificial intelligence, there are about to be big changes in the coming decades. As Carnegie Consulting puts it, “It’s important not to see this transformation as a quick-fix solution within rigid manufacturing processes and resources, but to recognize it as a long term commitment to changing the people, processes and culture of an organization in order to fully leverage the benefits of new technological opportunities.”

Yes, the changes can be overwhelming. But strategic business leaders will recognize this opportunity for what it is; a chance to upgrade, become more efficient, and stay ahead of the competition.

The specific strategies are countless, so to help get you started, we’ve outlined four actionable steps below that you can take to start overcoming these challenges.

The days of a large potential manufacturing workforce are over. Rather than complaining about the pitfalls of educational institutions or a lack of vocational schools, employers need to get creative.

The experts state there is a 2 million person skills gap.12 What does that tell us? Perhaps the skills gap isn’t simply due to a lack of qualified people. Perhaps it’s because employers aren’t doing a good job looking for them and many potential candidates are unaware of the new career opportunities that are available.

To attract talented young workers, companies can present their jobs as viable, long-term career opportunities.

Reevaluate your job postings. See if the language implies a static position with little room for growth, or a evolving career with a variety of learning opportunities.

Be vocal about debunking myths of the conditions of manufacturing, these perceptions are harmful to the industry and are preventing qualified workers from applying

Even if a company is able to fully staff their facility with top-notch qualified workers, the state of the industry is such that they will always require new training.

Tacking a list of procedures to the end of a Word document is not a sustainable way to train employees; especially when procedures are complex and continuously evolving. Technical writers and those responsible for producing the instructions will need to draw on educational principles to ensure that the larger influx of information is digested effectively by their audiences.

This means no more industry jargon, complex and convoluted diagrams, or text-heavy documents. People process information visually and retain information better when it’s broken up into smaller, concise components.

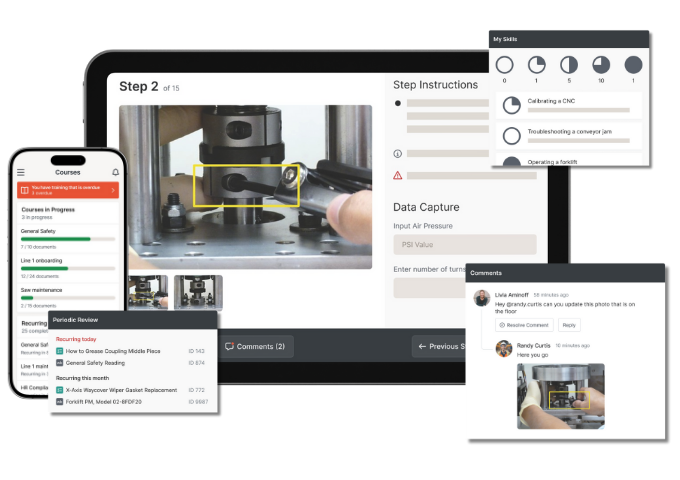

Implement a connected worker platform to create training materials faster, capture tribal knowledge, distribute revisions without delay and gather feedback for improvement.

Introduce visual elements (like photos and videos) into your instructions to convey complex procedures.

It isn’t enough to just train your employees. With complex procedures and dynamic work environments, you’ll need to ensure that you’re training well.

Many facilities already collect data across a variety of machines for safety and compliance reasons. But you should also be leveraging this data to show you how efficient and effective your processes are.

Companies should be effectively verifying that employees are getting the proper training. It’s no longer enough to just have a supervisor sign off on a training. Employees should be tracked, and important knowledge should be validated. This means tracking training procedures in real time and integrating validation into training materials. Furthermore, training materials should allow for collaborative feedback when 1 on 1 instruction isn’t possible.

Standard operating procedures (SOPs) exist to allow for process control and improvement. They serve as the foundation for initial training and future improvements for processes, ensuring that mistakes by less seasoned employees are prevented.

For new employees, being trained to the approved standard ensures that work is done correctly, by everybody, the first time.

Just as it’s important to create SOPs for maintenance of assembly procedures, it’s equally vital to create good SOPs for document revision and control.

While standardizing document revisions may not seem to be a top priority, it can have a real preventative impact when it comes to mitigating the cost of mistakes.

Feedback Loops

Create the ability to provide frequent two-way feedback.

Be Personable

Millennials want to be treated with respect, not just a number.

Keep the Challenges Coming

Those with strong work ethics require new projects to tackle and new idea to keep them interested and inspired.

Don’t Insult Intelligence

Patronizing or speaking-down to employees is the quickest way to lose both their interest and their respect.

Consider Co-Mentoring

Have an employee from an older generation help a younger team member understand work culture and processes, while the younger employee helps their partner manage technology and new tools at work.

Lead with a Purpose

Millennials workers are more likely to look for meaning and impact in their work and aren’t satisfied simply punching a clock.

Foster Creative Thinking

This gives younger employees opportunities to provide innovative solutions to business problems, feeling invested in the company’s success.

Be Aware of Work/Life Balance

A majority of millennials value this above all else, and is often cited as the reason for pursuing other employment opportunities.

Don’t be Boring

Evolution and innovation energizes millennials, give them an opportunity to be a part of cutting-edge technology improvements.

Create a Career Roadmap

The more opportunities for growth you can share, the easier it becomes to recruit new hires.

1 Deloitte analysis based on data from U.S. Bureau of Labor Statistics and Gallup Survey, 2015

2 “The skills gap in U.S. manufacturing in 2015 and beyond.” The Manufacturing Institute, 2015

3 “Out of Inventory: Skills shortage threatens growth for US manufacturing.” Accenture, 2014

4 “The skills gap in U.S. manufacturing in 2015 and beyond.” The Manufacturing Institute, 2015

5 “The skills gap in U.S. manufacturing in 2015 and beyond.” The Manufacturing Institute, 2015

6 “A Look Ahead: How modern manufacturers can create positive perceptions with the U.S. public.” The Manufacturing Institute, 2017

7 Gallup, Inc. “How Millennials Want to Work and Live.” Gallup.com, news.gallup.com/reports/189830/e.aspx

8 “The skills gap in U.S. manufacturing in 2015 and beyond.” The Manufacturing Institute, 2015

9 Ganger, Timothy. Visual Impact, Visual Teaching: Using Images to Strengthen Learning. Corwin, 2009

10 “Engaging and Empowering Millennials.” PricewaterhouseCoopers, 2014, https://www.pwc.com/gx/en/hr-management-services/publications/ assets/pwc-engaging-and-empowering-millennials.pdf

11 “Embracing Digital Technology: A New Strategic Imperative.” MIT Sloan Management Review, 2013, http://sloanreview.mit.edu/projects/ embracing-digital-technology

12 Murphy, Cait. “Is There Really a Skills Gap?” Inc., www.inc.com/magazine/201404/cait-murphy/skills-gap-in-the-labor-force.html