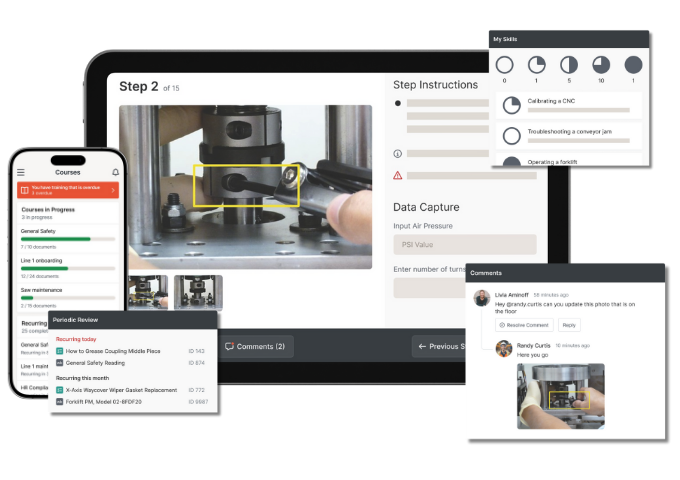

Knowledge Management

Capture and control operational knowledge in one place. Ensure your workforce always has access to accurate, up-to-date procedures and work instructions, no matter where they are.

Learning Pathways

Turn your standard work into structured training. Build courses, assign teams, and track qualifications so every worker is confident, compliant, and job-ready.

Operational Workflows

Coordinate frontline work with built-in checklists, data capture, and work order tracking. Ensure consistency, reduce downtime, and enforce standards at scale.

Worker Collaboration

Give workers a voice in process improvement. From feedback to approvals, connect people and teams to continuously improve how work gets done.