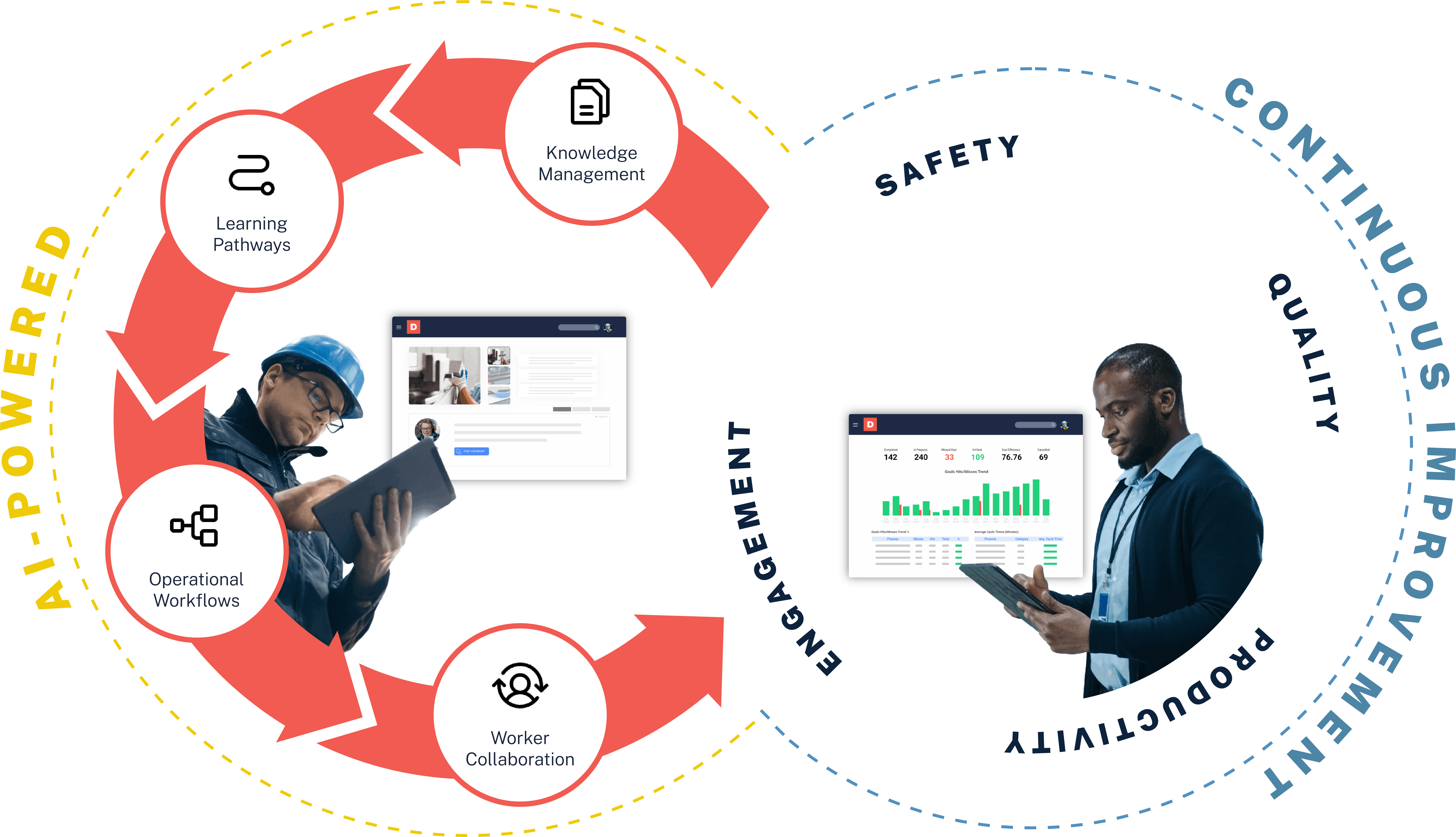

Dozuki ensures workers are trained, assessed, and qualified with on-demand access to critical knowledge. Giving manufacturing operations a skilled, resilient workforce.

Build training content from the same procedures your workforce follows on the floor. Align learning with execution so the right behaviors are reinforced in real work, not just in the classroom.

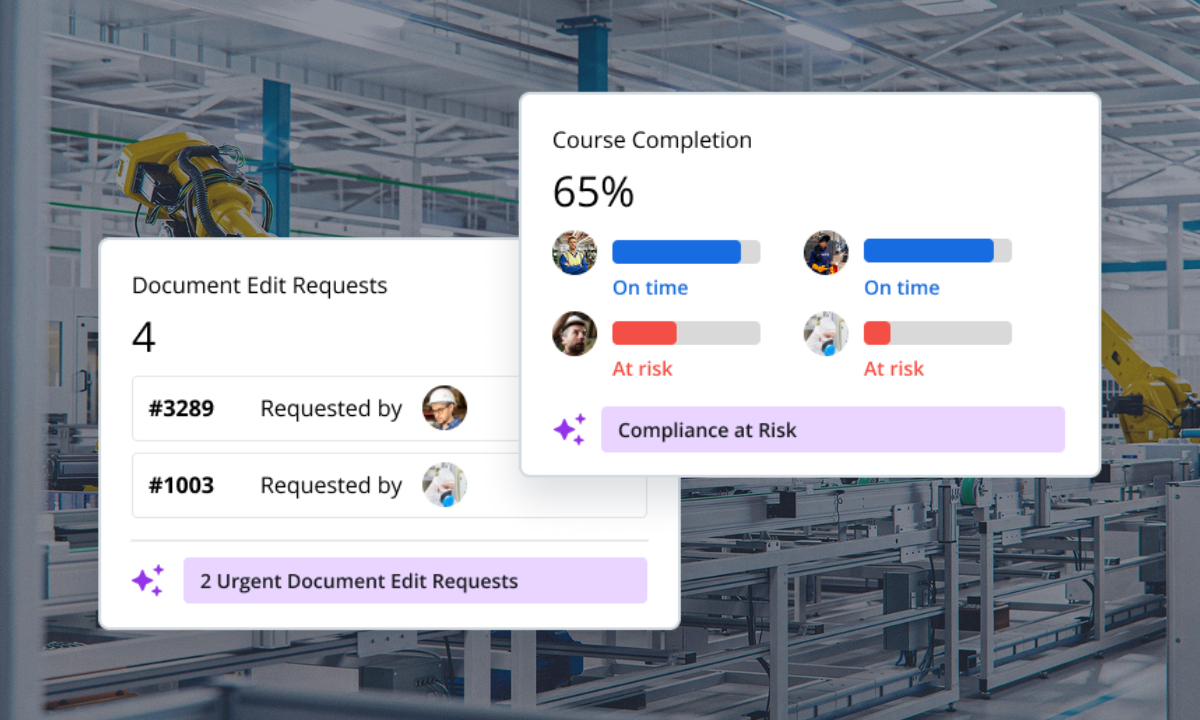

Gain a real-time view of who is qualified to do what across teams, shifts, and sites. Let AI do the heavy lifting of identifying gaps and guiding development.

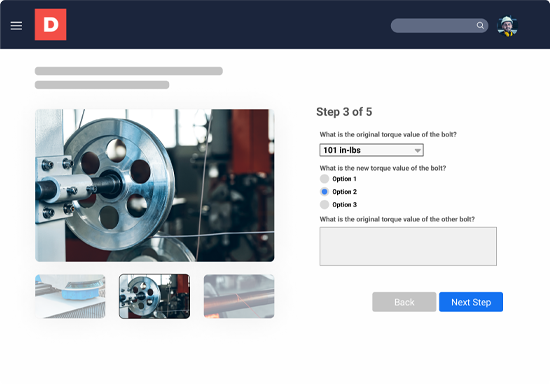

Use AI to generate quizzes instantly from standard work. Validate comprehension without spending hours creating or maintaining assessments.

Deliver training to the right people, at the right time, in the right language. Make learning available where work happens.

Bring external training libraries into the same system as your operational knowledge. Deliver one cohesive learning experience instead of disconnected systems.

Deliver structured training paths by role, location, or responsibility. Ensure the right people always get the right training without manual coordination.

Refresh critical knowledge without lifting a finger. Automate retraining based on time, role changes, or procedure updates.

Use the TWI Institute methodology to break complex jobs into teachable steps. Deliver training in a consistent, repeatable format that builds confidence and quality.

Maintain a single source of truth for workforce qualifications by syncing Dozuki with your LMS, HRIS, and compliance platforms.

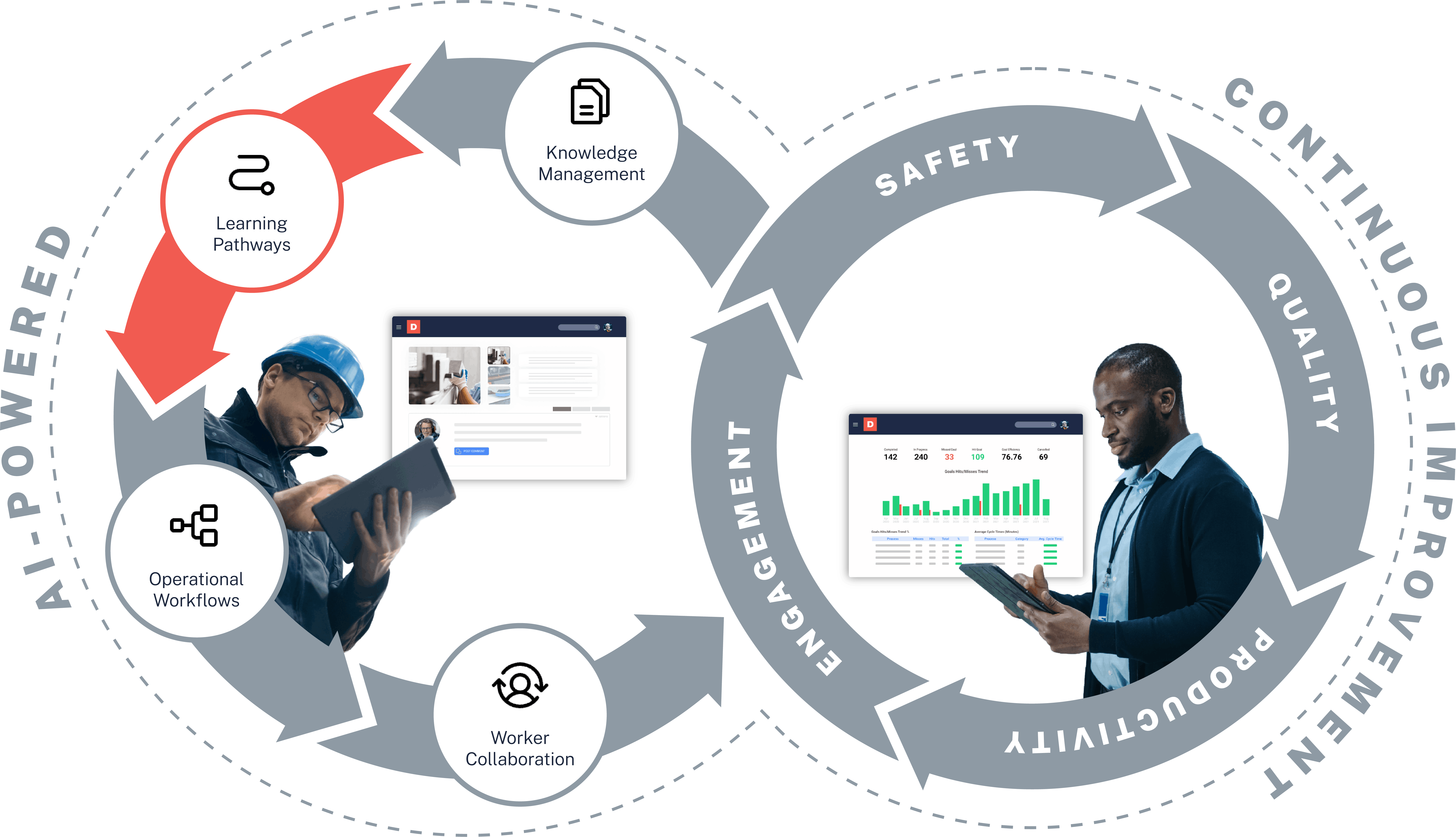

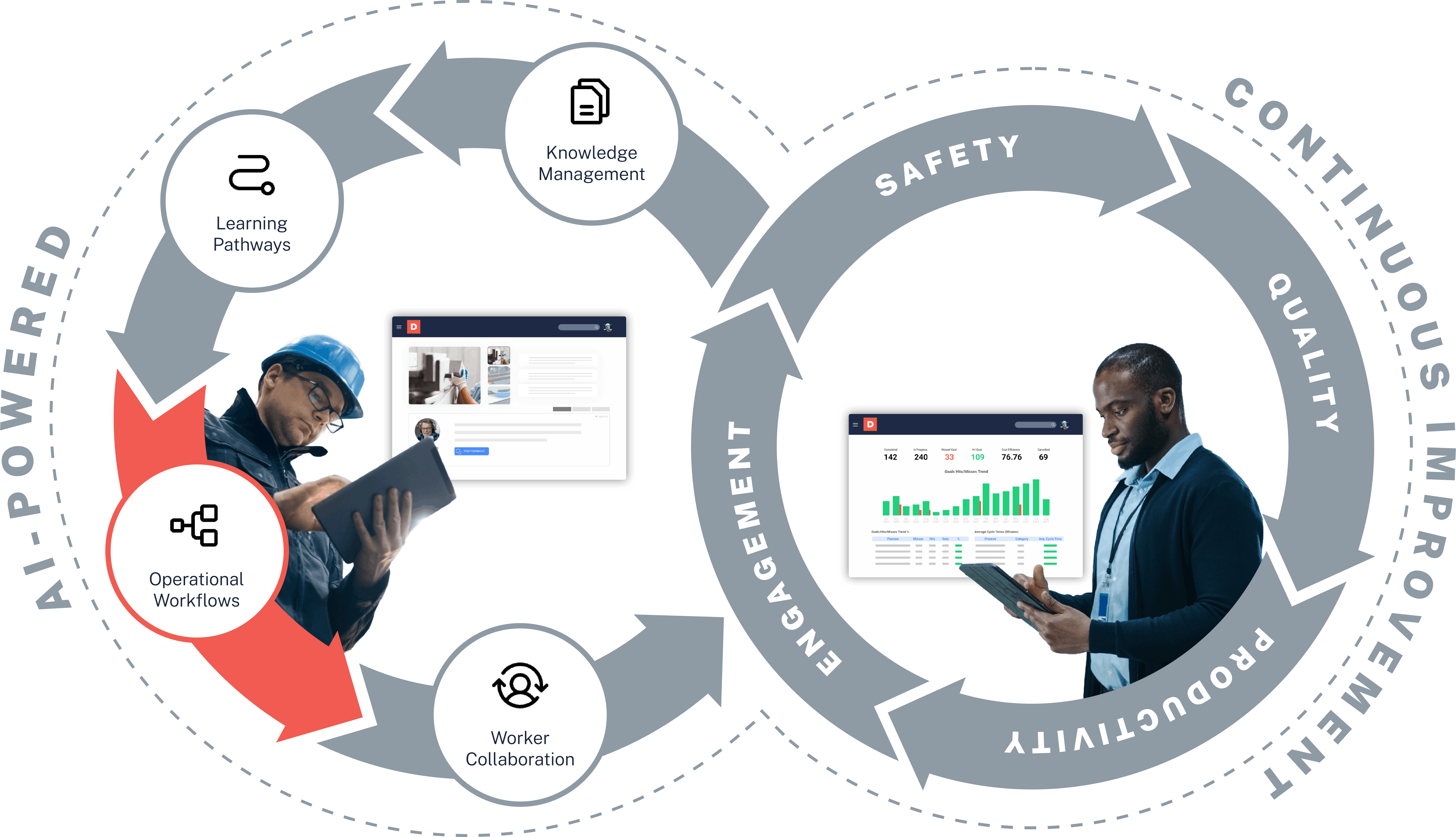

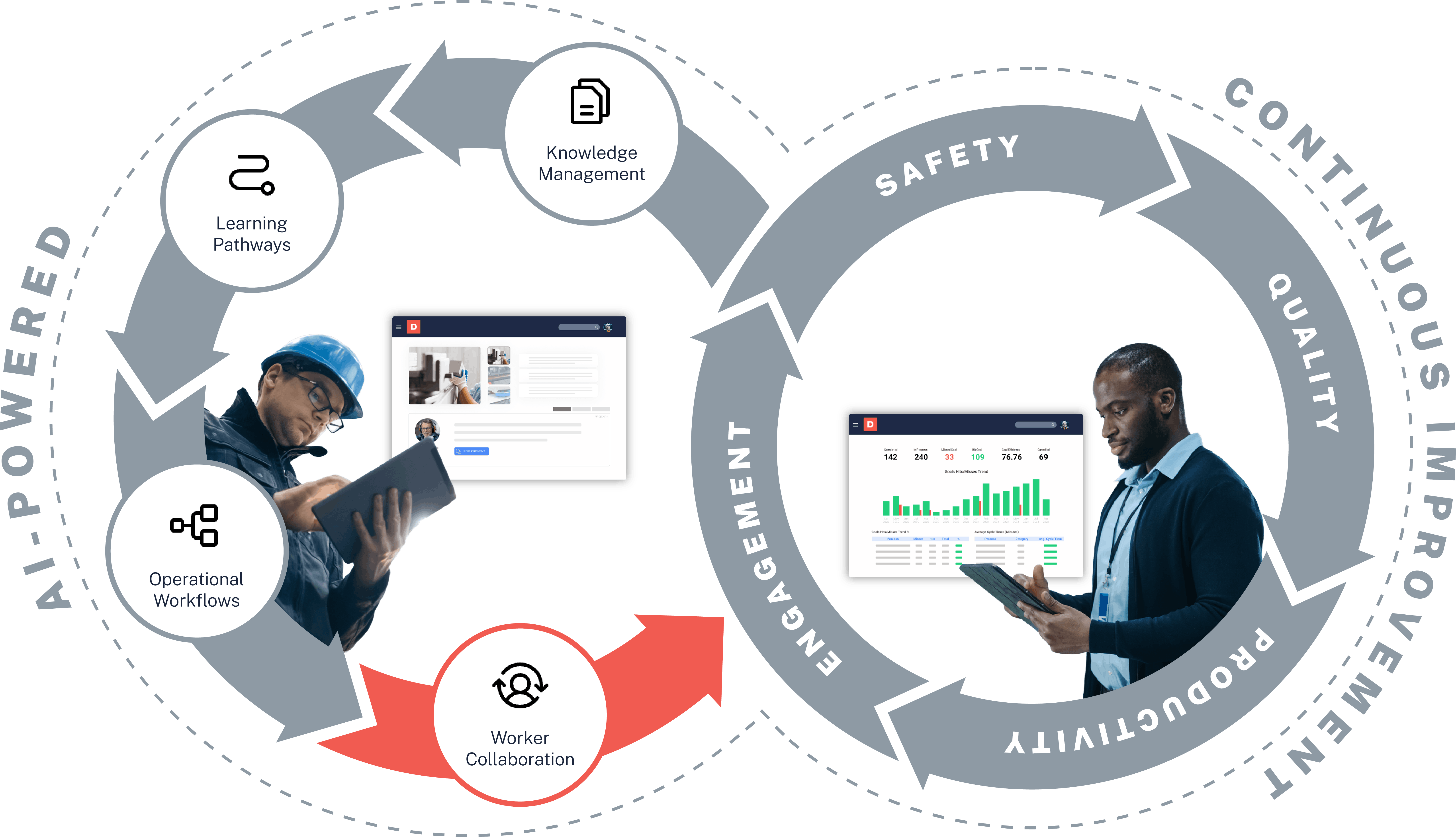

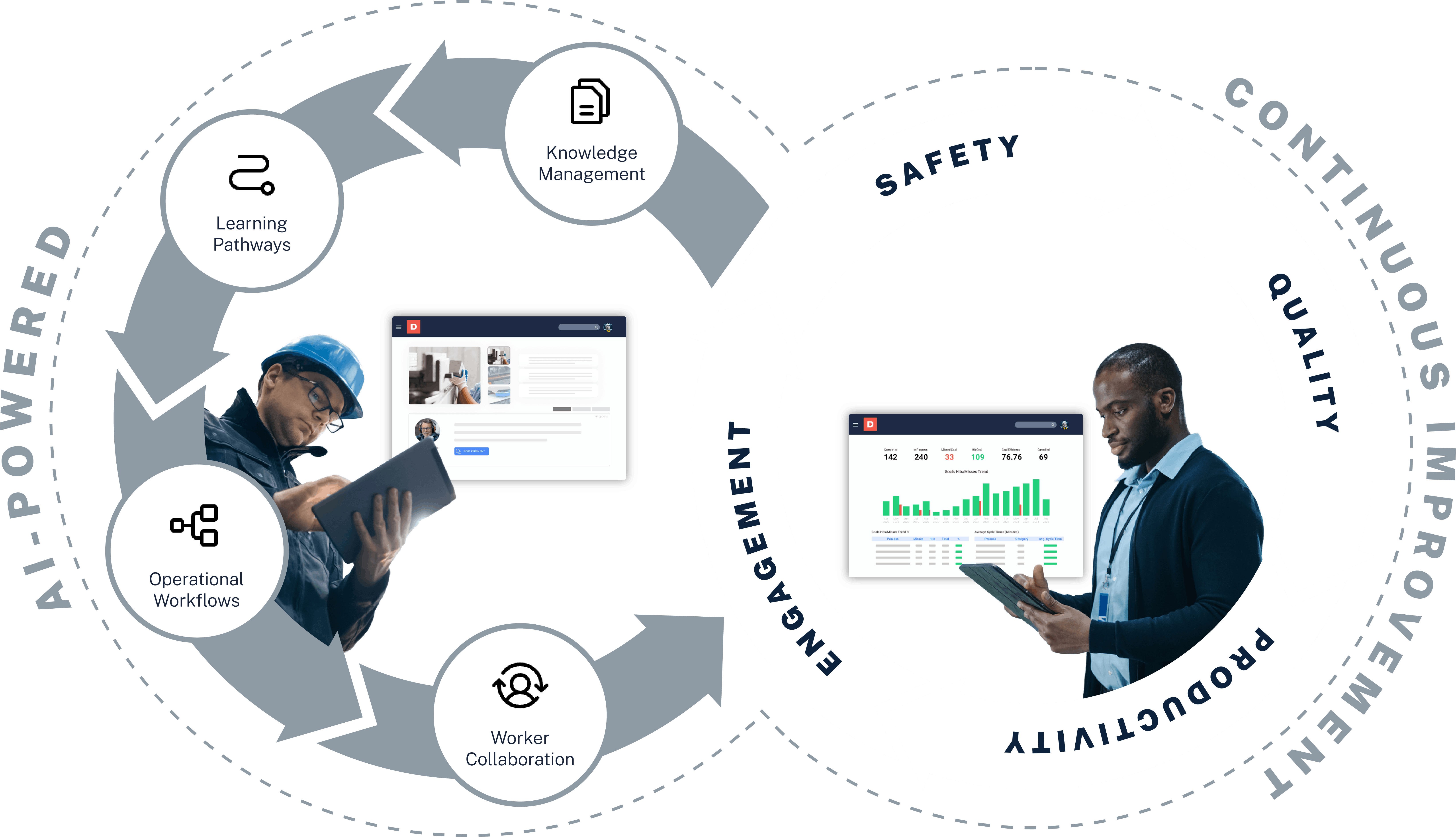

Training should do more than check a box. With Dozuki, your training efforts are guided by real performance data and evolving business needs.

You can identify exactly where skills are lacking, prioritize high-impact areas, and make every learning initiative count toward measurable outcomes.

Frontline readiness is critical, especially when production demands shift fast. Dozuki helps you onboard and cross-train workers with digital training curriculum built from your operational standards.

Whether it’s a new hire or a team member rotating roles, everyone gets the training they need to be productive from day one.

Staying compliant shouldn’t rely on spreadsheets or manual reminders. Dozuki automates your compliance workflows by triggering retraining when standards change and tracking certifications by role.

You’ll always be audit-ready with accurate, up-to-date training records tied directly to real operational needs.

When employees are trained with purpose, performance improves. Dozuki equips your teams with structured, job-specific learning that builds both comprehension and proficiency.

With training that reflects actual job instruction, your workers execute more consistently and make fewer mistakes on the floor.

Authoring training content manually can’t keep up with the pace of change. CreatorPro AI removes that bottleneck by generating training curriculum directly from your standard work.

From individualized quizzes to entire course modules, Dozuki helps you turn knowledge into structured learning with a fraction of the effort.

Training disconnected from real work leads to inconsistency. Dozuki fixes that by linking your training directly to your standard operating procedures.

The result is a workforce that executes every job the right way, every time, no matter the shift or site.

Automate retraining when procedures change, ensuring workers stay aligned with the latest standards.

To support rapid expansion into a new 750,000 sq. ft. facility, Airstream overhauled its outdated training program with Dozuki. By replacing paper-based systems and tribal knowledge with digital standard work, the team created structured onboarding and job-specific training tied directly to real tasks.

Turnover dropped by 83%, and trainer bandwidth improved as new hires gained clarity and confidence from day one. Training became consistent, measurable, and aligned with operations, setting the stage for long-term workforce development and shop floor success.

Facing high turnover and inconsistent training results, General Mills reimagined how employees were trained and qualified. Using Dozuki, they built a structured digital training program based on actual work processes, not generic theory.

This shift allowed the team to reduce overall training time by 62% while increasing engagement, ownership, and job performance across the floor, from new hires to seasoned operators.

Facing a retiring workforce and widening skills gaps, this Fortune 500 manufacturer needed to train new hires faster and more consistently. By replacing outdated tribal knowledge with structured digital curriculum and self-paced video training, they empowered employees to ramp up quickly, often mastering new skills in a single day. The Dozuki Learning Pathways platform enabled trainers to build scalable role-based programs and gave new hires confidence from day one.

In just one month, they reduced onboarding time by 90% and saved $80K annually per plant, while building a future-proof training program that continues to evolve with their workforce needs.

“Dozuki helps us train 58% faster, a huge win!”

“Training is now continuously updated, based on worker feedback.”

“We've never trained people this quickly. Becoming certified operators in weeks instead of a year.”

“Dozuki helped reduce our workforce turnover by 83%.”