These are silent system failures. Information doesn’t move. Action doesn’t happen. And the illusion of safety persists, until it breaks.

The Deepwater Horizon disaster is a sobering example. Investigations revealed that outdated procedural documents and broken communication channels directly contributed to the fatal blowout. Eleven lives were lost and the company incurred more than $60 billion in damages.

Dozuki solves this by connecting procedures, feedback, and training into a single system. Every safety concern is tracked. Every update is controlled. Every piece of training is verifiable and audit-ready. From the moment a hazard is observed, the resolution process begins — and it doesn’t stop until that hazard is eliminated.

Build Safety Teams for Accountability and Agility

A proactive safety system requires distributed ownership. Dozuki allows manufacturers to create layered safety teams with clearly defined roles and escalation paths.

Operators are the first line of defense. They are closest to the work and best positioned to recognize emerging risks. With Dozuki, they submit structured, timestamped feedback from within procedures — transforming observations into actionable data.

Operator Safety Teams take this frontline input and make process updates based on real-world conditions. These experienced workers conduct audits and edit procedures, acting as stewards of practical change.

Department Safety Teams review proposed changes from a strategic standpoint. They assess whether updates impact safety or performance, ensuring departmental alignment without introducing bottlenecks.

Plant Safety Teams provide oversight across the entire facility. These site-level managers ensure feedback loops are functioning, processes are audited, and any risks are addressed with plant-wide coordination.

Standards Teams handle final sign-offs and publication. They confirm that changes align with company-wide policies, training content is synchronized, and retraining triggers are properly configured. Nothing goes live without their approval.

Observation Teams span all levels of the workforce and conduct cross-departmental audits. This peer-review structure ensures that fresh eyes are continuously assessing environments and reinforcing a culture of safety ownership.

Case Study: Transforming Safety Approval Cycles

A global heavy equipment manufacturer reduced safety approval cycles by 97% after switching to Dozuki. Before the platform, SOP updates lingered in inboxes, policy reviews were inconsistent, and training compliance was difficult to track.

After adopting Dozuki, approvals that once took weeks were completed in hours. Audit data became traceable. Hazard reporting gained structure. Training records became centralized and visible.

The real transformation was cultural. Safety moved from a compliance task to a shared responsibility. Hazards were addressed quickly, and performance was no longer guesswork — it was trackable, repeatable, and continuously improving.

Building Proactive Feedback Loops

Feedback is your early warning system — but only if it’s monitored and acted on. Dozuki embeds real-time comment tools into every procedure step. Operators flag issues. Supervisors triage them. Structured approval workflows route updates for review.

Minor changes can be published instantly. Major changes trigger multi-level sign-offs. The result is a feedback engine that improves every week.

In 2021, an OSHA citation in a Texas packaging plant highlighted a tragic example. A machine severed a worker’s arm two weeks after the operator flagged a faulty guard — on a clipboard. That note never left the floor. With Dozuki, that feedback would have triggered alerts, updates, and retraining before the injury occurred.

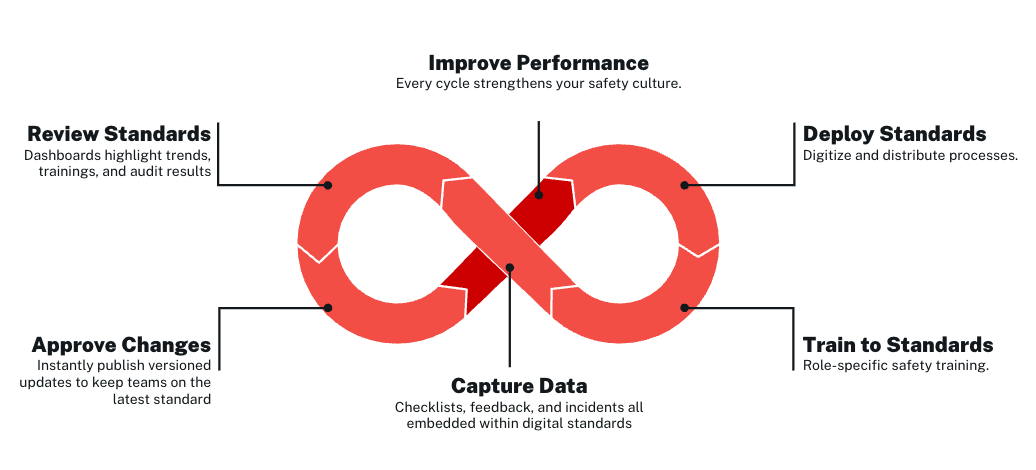

From reviewing standards to deploying updates, from embedding checklists to capturing incidents — every function is built to strengthen safety performance at every level.

Making Safety Knowledge Accessible at the Point of Use

Safety procedures can’t just exist — they have to be usable. Dozuki breaks down access barriers with instant delivery, language translation, and version control.

QR codes placed directly on machines link to the exact procedure in the user’s native language. Over 100 languages are supported, ensuring comprehension across diverse workforces. When updates are made, Change Aware technology ensures operators acknowledge them before proceeding. Every change is logged, reviewed, and traceable.

This means safety knowledge is not just available, it’s relevant, current, and verified — at the exact moment it’s needed.

Ensure Competency, Not Just Compliance

First-day employees are statistically the most vulnerable. Dozuki addresses this by turning procedures into curriculum. Every SOP becomes part of a four-phase training model.

In the Awareness phase, workers know how to access the latest standard via QR code and version history. In Comprehension, knowledge is tested with quizzes and knowledge checks. Proficiency is demonstrated through trainer assessments, with supervisors observing workers in real time. Mastery is earned when workers can train others, using a 0-to-4 skills rubric that shows how deeply they understand the task.

This system helps manufacturers proactively identify skill gaps, implement targeted training, and build redundancy into their teams. Because all training is tied directly to the current standard, any update automatically triggers retraining — closing the loop between procedure and practice.

Continuous Safety Improvements

A proactive safety culture requires constant refinement. Dozuki captures institutional knowledge through visual, step-by-step guides that follow design best practices for clarity and usability.

Safety checklists are completed before every shift. Cross-departmental observations identify blind spots. Support for over 100 languages ensures accessibility. Periodic reviews prompt reassessment of every process on a scheduled cadence.

QR codes can be customized by content type — one for a checklist, one for a video, another for a maintenance guide. This modular approach enables a self-led learning environment where safety, productivity, and improvement live side by side.

The ROI of Safety Culture

The numbers speak for themselves. A major energy customer cut audit times from multiple days to under five minutes. A Fortune 100 manufacturer reduced approval times by 97%. Over 100 languages are supported across global operations.

But the real return is peace of mind. Every employee has the tools, knowledge, and structure to work safely and go home healthy.

The Path Forward

Safety isn’t a software feature. It’s a systemic mindset. Dozuki provides the digital infrastructure to bring that mindset to life — connecting procedures, training, feedback, and execution.

If your safety program still relies on tribal knowledge, spreadsheets, or siloed systems, the threat isn’t just noncompliance — it’s operational continuity.

It’s time to raise your safety standards.

FAQ: Connected Worker Platforms & Safety

How does Dozuki make safety proactive, not reactive?

Dozuki embeds safety into the daily execution of work. Feedback loops are structured, hazard reporting is tracked in real-time, and training is always aligned with current procedures.

Can we customize safety roles and workflows?

Yes. You can create layered safety teams—operators, safety leads, supervisors, standards teams—with clearly defined responsibilities, approval steps, and retraining triggers.

How does Dozuki handle incident reporting and follow-up?

Operators can report issues directly in a procedure. These are routed to the appropriate team, tracked with full visibility, and tied to SOP updates or training requirements.

Can the platform support global teams?

Yes. Dozuki supports over 100 languages and provides QR code access at the point of use. Every worker can access the right procedure in the right language instantly, no matter where they work.

How does the system handle retraining for safety updates?

When a procedure is updated, Dozuki automatically triggers retraining for relevant users. This ensures every worker stays current with safety standards without manual intervention.