Continuous Improvement

5 min read

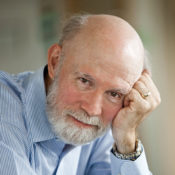

Lean Thinking vs. Cost Cutting with James Womack

When properly applied, lean manufacturing principles cut costs by reducing waste and focusing on value. But many companies make the vital mistake of confusing cost cutting with lean thinking. To better understand the relationships between costs, waste, and value, we sat down with one of the foremost experts of lean, Dr. James Womack, to discuss the foundational elements of what makes lean thinking, lean.

Lean Thinking: The Idea That Changed the World

These manufacturing concepts can be traced back to the early innovation of Henry Ford in the 1900s. But lean wasn’t widely adopted until Taichii Ohno successfully developed the Toyota Productions System in the 1930s.

In 1990, Dr. Womack’s book, “The Machine That Changed the World”, first popularized the lean concepts in the automotive industry and began spreading the methodology throughout a variety of business types. Since thenDr. Womack has published many books on the topic, including “Lean Thinking” and “Gemba Walks.” He also founded the Lean Enterprise Institute in 1997; making him one of the foremost experts on all things lean.

In 1990, Dr. Womack’s book, “The Machine That Changed the World”, first popularized the lean concepts in the automotive industry and began spreading the methodology throughout a variety of business types. Since thenDr. Womack has published many books on the topic, including “Lean Thinking” and “Gemba Walks.” He also founded the Lean Enterprise Institute in 1997; making him one of the foremost experts on all things lean.

What is Lean?

With a rich and complicated history, lean manufacturing principles have evolved and adapted to changing industries for over a century. Due to its now widespread use, misconceptions of the term continue to persist. Therefore, it’s important to understand its roots and intended use:

Dr. James Womack:

The choice of the word was the idea that if you thought carefully, and organized yourself in the right way, you might create more value with less waste. So in broad brush, that’s all we meant by lean — more value with less waste. The Toyota guys had a way to do that in a production setting, called the Toyota Production System. They also had some other ways to do it in product development, developing suppliers, and supporting customers. So in everything they were doing, they were trying to create more value with less waste.

Focus on Providing Value

When manufacturers are so focused on streamlining their operations and improving efficiency, it can be difficult to take a step back and assess the value of the thing you are producing. As a lifelong student of lean thinking, Womack describes the problem:

Womack:

The problem with the connotations of the term ‘lean’ is that when people hear it, what that sounds like is cost reduction — and that’s never actually what we meant. It seemed to us that a large part of the manufacturing world’s problem was the difficulty in figuring out what the customer really valued as opposed to the bundle of stuff that you are giving them.

More Value, Means More Work

Typically, we think of waste as a non-value adding activity within our operations. In effect, looking to create the same amount of value with fewer resources.

What waste, in the lean sense of the word, means, is an absence of value provided to the customer, not a specific manufacturing process. Womack states that to truly be lean, we must be constantly questioning the value we provide to customers:

Womack:

What we were really trying to figure out is how you can create more value, which might even be a different sort of value than you were originally thinking. In doing that, you might take a lot of the waste out, which is to say a lot of the cost out.

If you did it correctly, you’d have plenty of work for everybody, because if you create more value for customers, typically they want more. If you’re only cost cutting your value proposition in the short term, then you might make a few extra bucks initially, but then your customers eventually figure out that you’re cutting corners.

Asking the Right Questions

Understanding what the customer truly wants isn’t an easy task. Often times, the customer themselves may not be aware of the need or answer until you begin to ask the right questions.

Womack:

One of my books that got the least attention is called “Lean Solutions,” I provide a framework to work back from what the customer really wants — which is typically not a brilliant product (good or service), but an answer to the question they’ve been asking.

Maybe, this answer is to a question that they hadn’t thought about asking; but now with some prompting they realize, “oh yeah, that’s what I meant.” Too many companies take the value proposition as a given and try to do the same thing, just with less, which is a shame.

Topic(s):

Continuous Improvement

Related Posts

View All Posts

Continuous Improvement

A Lesson in Lean Manufacturing From the North Pole

4 min read

If Santa Claus ran a toy company, he’d have the best lean manufacturing operations in the industry. A lean analysis shows that he delivers custom tailored products to every...

Continue Reading

Continuous Improvement

Why Standard Work is a Contradiction

4 min read

We recently wrote a popular article about a major mistake at a nuclear waste facility. In short, we cited poor standard revision processes as the root cause of the mistake,...

Continue Reading

Continuous Improvement

Book Club: “The Joy of Lean”

6 min read

The Dozuki book club is your go-to place for industry books and resources. Our team curates knowledge from industry experts, letting you identify key takeaways and start...

Continue Reading