The True Cost of Paper-Based Documentation

Paper is viewed as a necessity in the workplace.

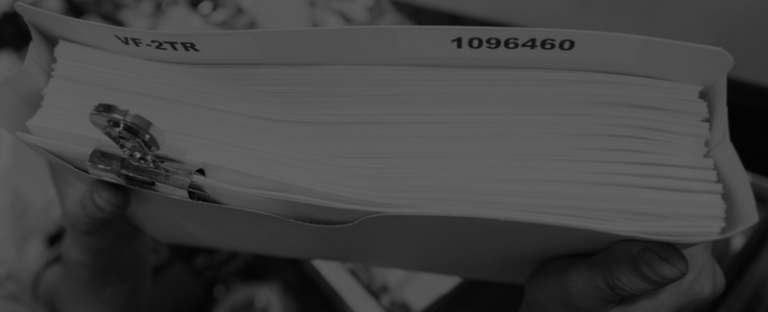

It is used for a variety of reasons, from travel documents to field service or product manuals to employee on-boarding and training handbooks. It’s become such a staple, companies don’t even think twice about the actual cost of these reams of paper ⎼ including quality issues and lost time ⎼ until now.

Paper Doesn’t Just Grow On Trees

Let’s start with the big one: cost.

At about $12.99 a ream (on average), it’s easy to brush off the annual dollar amount spent on paper. But this cost adds up.

According to one study, the average company uses about 10,000 sheets of paper (20 reams) per employee per year. $12.99 x 20 = $259.80. Multiply that by 50 employees, and you already get a pretty big number, $12,990 to be exact. Not only spent, but wasted.

Research has shown that up to 45% of this paper ends up in the trash, that's quite a bit of money that could be put back into the company. We have advanced in so many ways, so why, in this area, do we seem so behind?

Wasted Time Is Productivity Lost

Paper doesn’t only cost a lot to purchase - working with it can also create issues with accuracy and standardization. An employee on the shop floor or out in the field is far more likely to complete a procedure using tribal knowledge rather than searching through emails, manuals, or files to find the most up to date work instructions.

It is also very likely that updates in procedures may not reach everyone, leading to out of date documentation being used. This has the potential to lead to mistakes and standardization issues with even the most experienced employees, costing your company wasted money and time.

Formatting And Tracking Nightmares

Updating paper-based processes can be extremely tedious and time consuming. Formatting documents in Microsoft Word and other platforms can be a nightmare; the addition of one table or photo can ruin an entire document and take hours to correct.

Updating paper-based processes can be extremely tedious and time consuming. Formatting documents in Microsoft Word and other platforms can be a nightmare; the addition of one table or photo can ruin an entire document and take hours to correct.

Combine formatting problems with manually tracking document changes and ensuring the correct versions are distributed to employees, and the hours start to add up.

This is time wasted. Time that could be better spent growing your business.

Written by Leslie Bloom

Related Posts

Blueprint for Brilliance: Takeaways for Joining the Ranks of the World’s Most Productive Companies

LNS Research recently released its 2025 Benchmarking the Journey of the World’s Most Productive Companies report, and the findings are a wake-up call for the industrial...

Continue ReadingThe Future of Manufacturing in 2026: Empowering the Connected Worker

Key Takeaways (The TL;DR) Connected worker initiatives will be central to driving efficiency, safety, and productivity in 2026. Manufacturing technology is advancing...

Continue ReadingWhy Workforce Agility Will Define 2026

In 2026, manufacturers won’t be judged solely by what they produce, but by how fast they can adapt. The year ahead brings a wide range of scenarios: cautious optimism...

Continue Reading