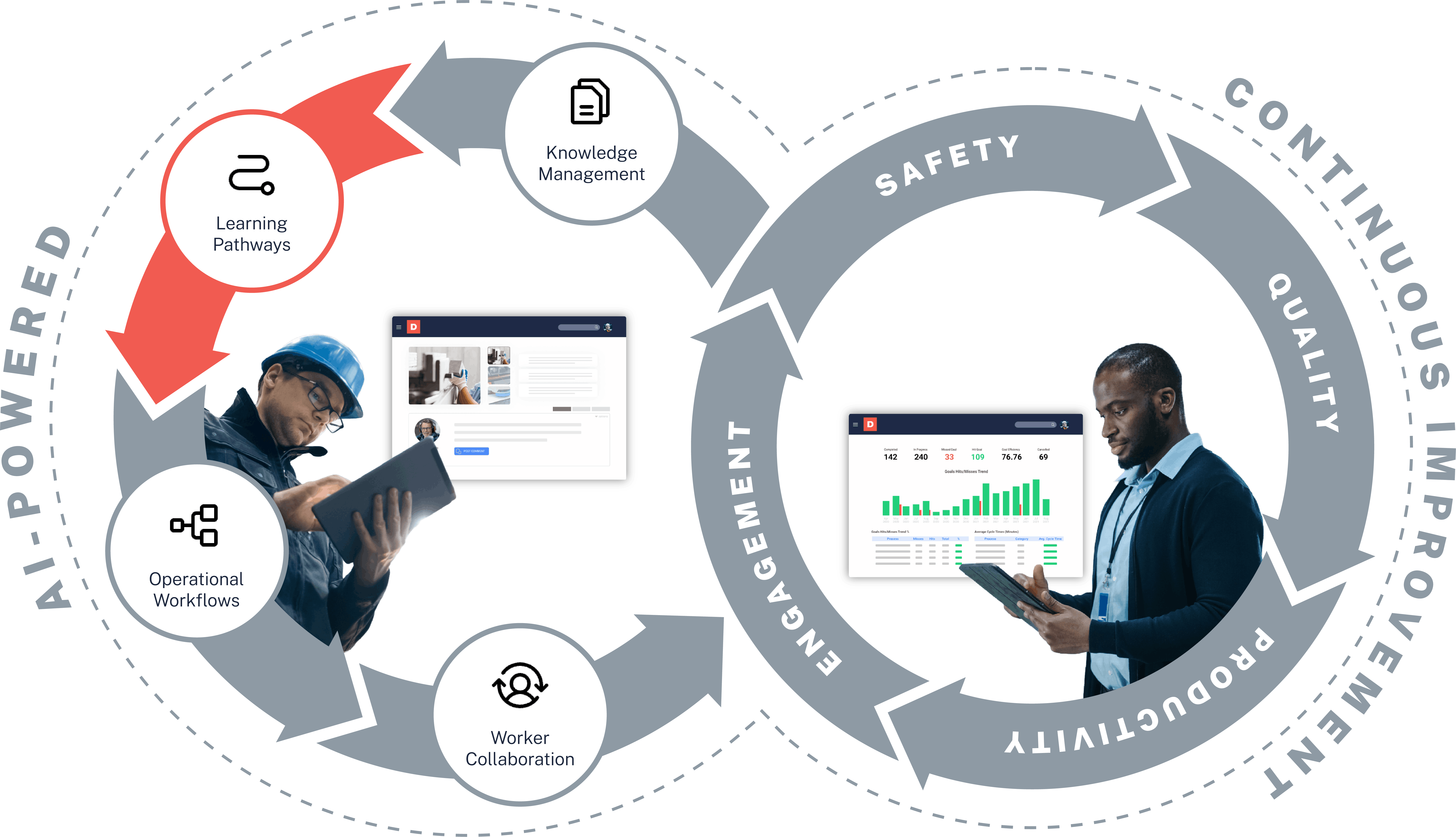

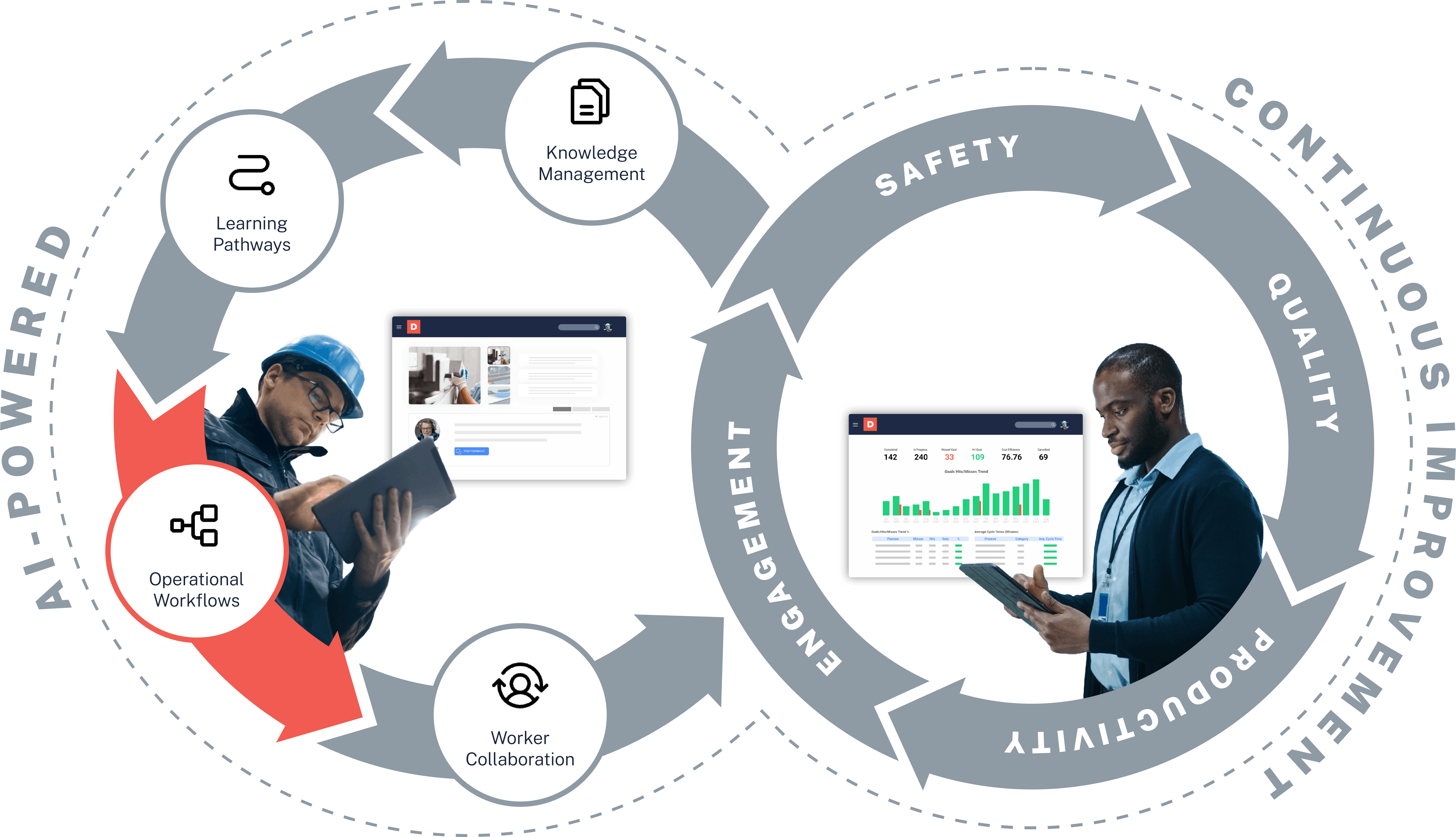

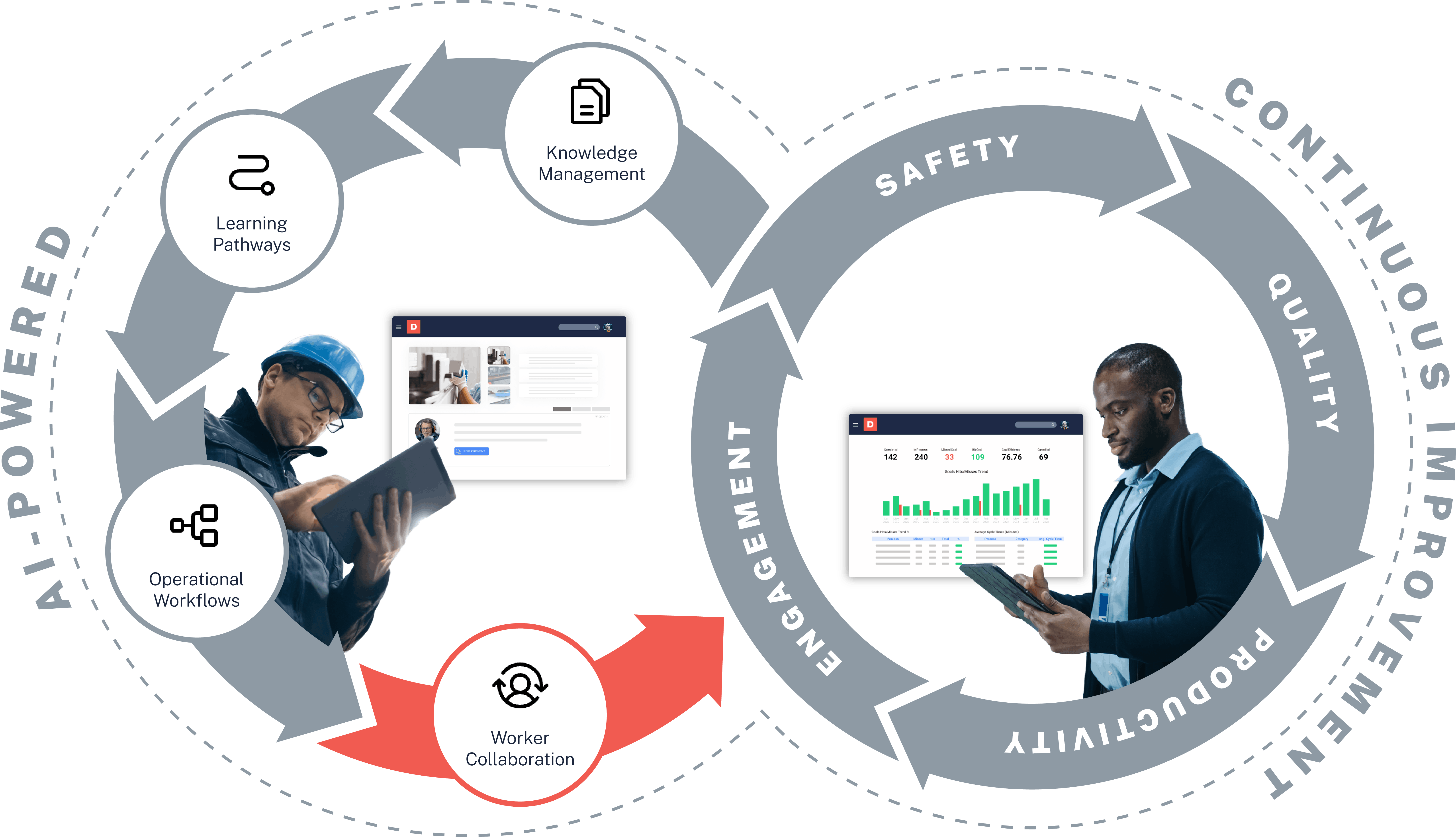

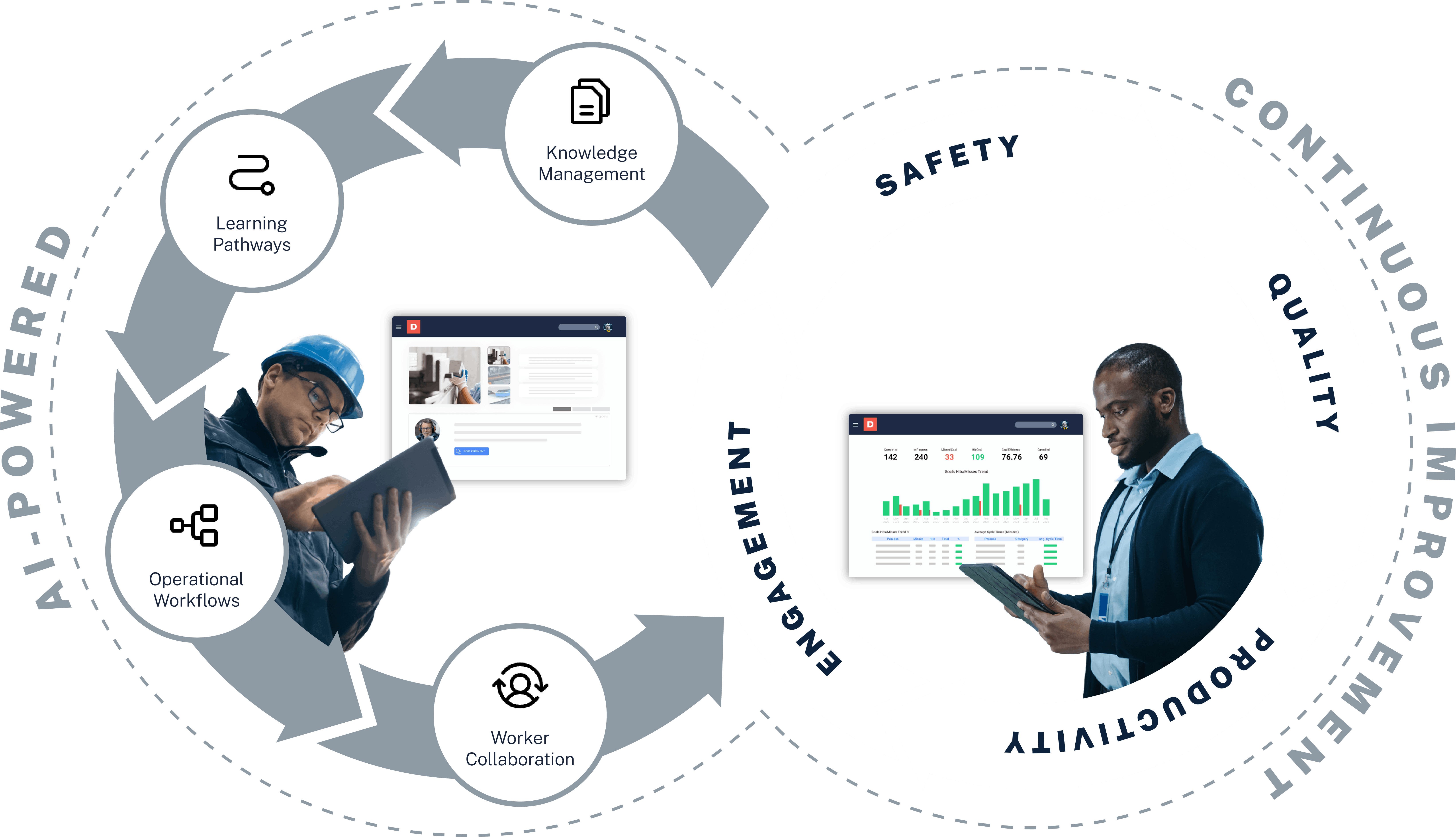

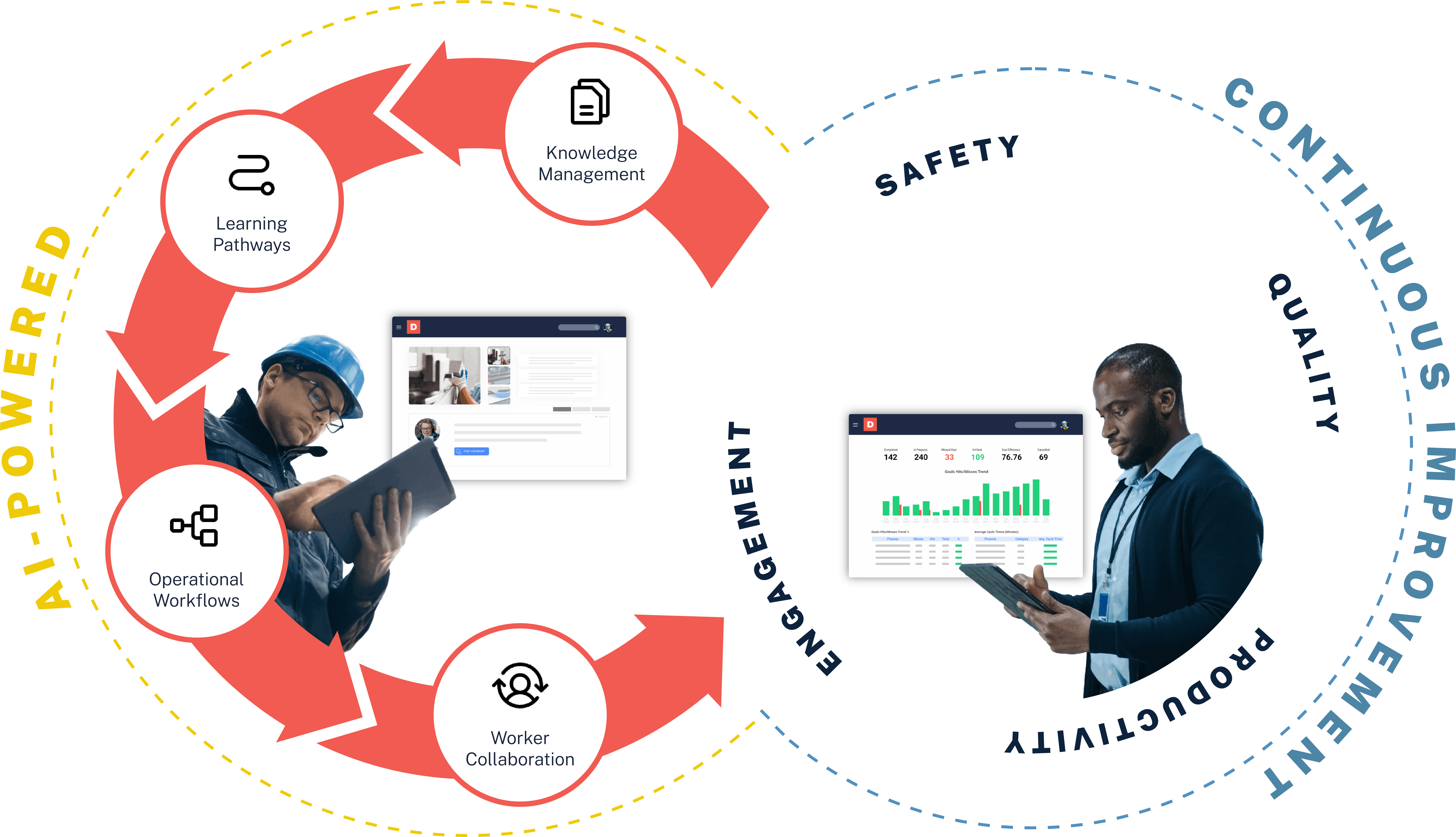

Dozuki is an AI-powered solution for manufacturing operations to ensure standardized, accessible, and up-to-date information to drive efficiency and quality across your workforce.

Capture, document, and standardize work procedures with rich visuals and AI-powered creation tools. Ensure every worker learns and performs tasks the right way, every time.

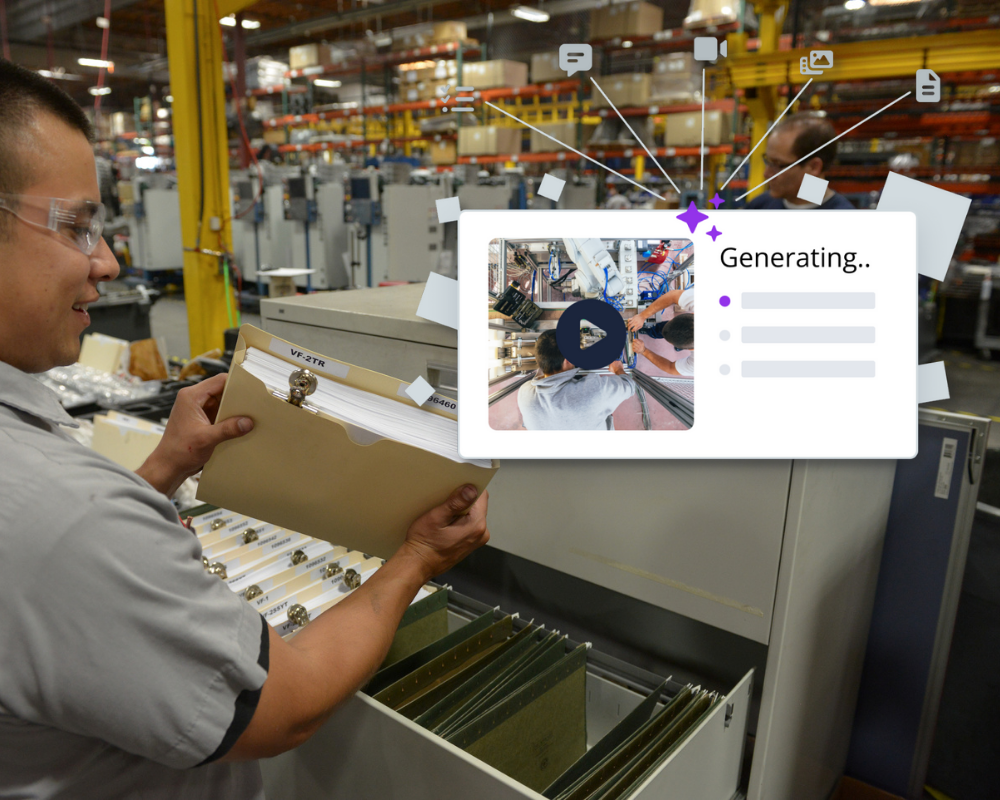

Modernize your documentation and training by instantly converting outdated files or video recording work in real time. Save time and resources while building scalable, standardized content.

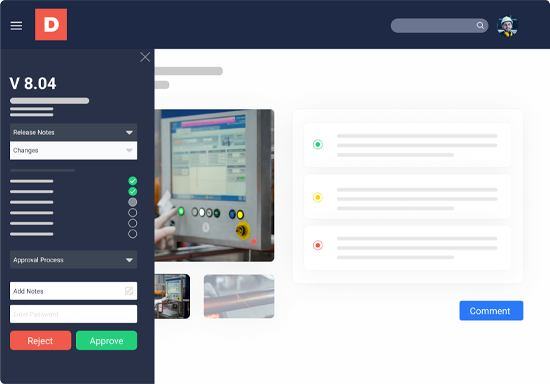

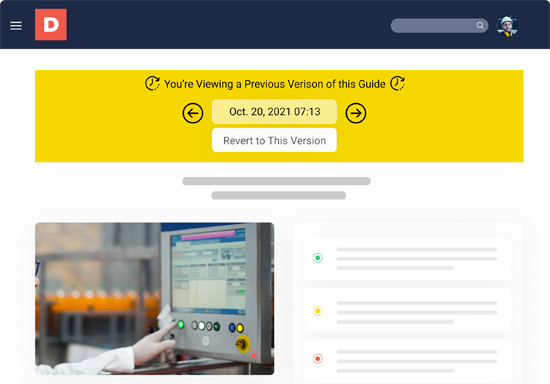

Manage revisions, approvals, and publishing with built-in controls. Maintain accuracy and traceability across every site with centralized governance.

Ensure that all frontline teams can access the latest standards from any device or location. Drive performance through language support, instant updates, and offline availability.

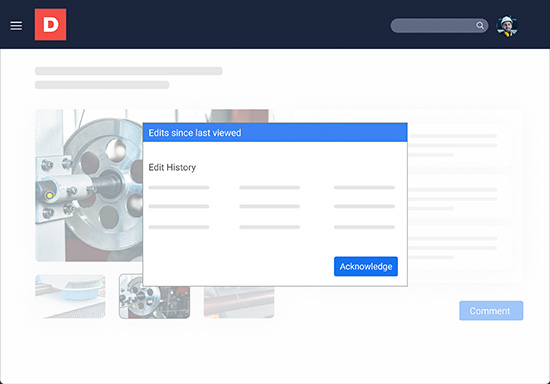

Clearly explain what changed, why it changed, and what workers need to do differently. Drive true compliance with update acknowledgment and tracking.

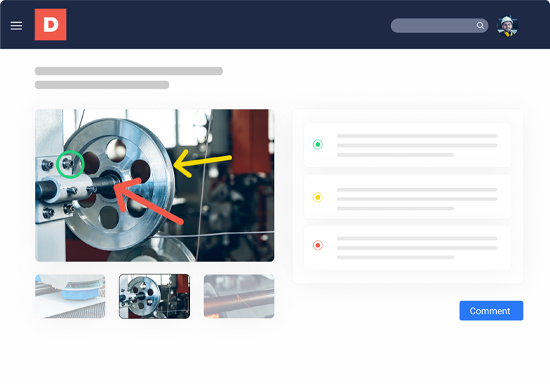

Empower teams to submit process feedback in real time and track that input through to published updates. Build a living system that gets smarter with every improvement.

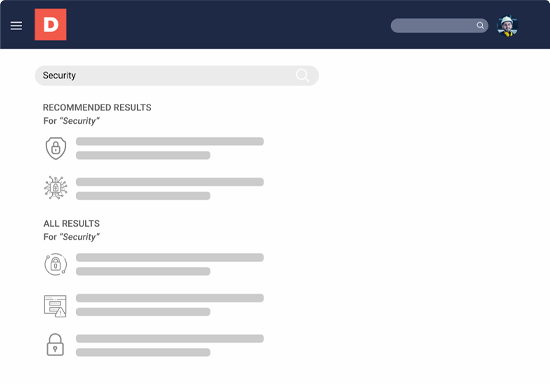

Workers can ask questions in natural language and get contextual answers drawn directly from verified procedures. Reduce downtime and increase confidence on the floor.

Coordinate releases of new procedures or changes so teams are never caught off guard. Automate audits to ensure nothing goes stale.

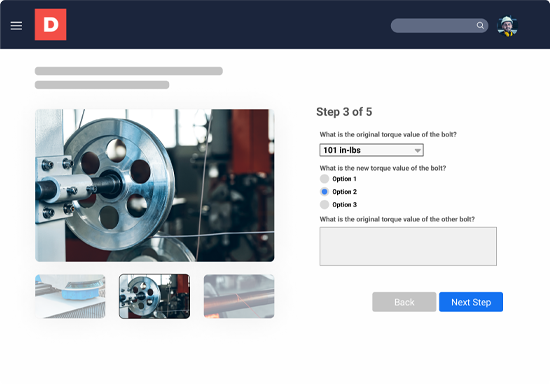

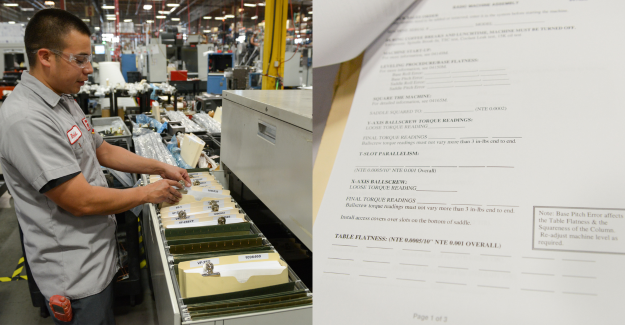

Allow workers to enter critical process data, verify task completion, and enable supervisor oversight, all directly within digital instructions.

Connect Dozuki with the rest of your tech stack to eliminate data silos and improve enterprise visibility across operations, training, and compliance.

Raise the bar on how operational knowledge is captured, controlled, and scaled

When procedures vary from shift to shift or site to site, quality and safety suffer. Dozuki eliminates that variability by providing a single, centralized source of truth that every worker can access, regardless of role or location.

With standardized, media-rich instructions, your teams operate with greater consistency and clarity, improving outcomes across the board.

Speed matters when onboarding new employees or shifting team members between roles. Dozuki reduces ramp time with step-by-step instructions that support workers in the flow of work, removing the need for informal job shadowing or confusing binders.

New and rotating workers gain immediate access to clear, visual guidance that accelerates their path to productivity.

Regulatory and internal compliance require full control over documentation. Dozuki makes it easy to manage versions, track approvals, and maintain a complete audit trail within a single platform.

You can ensure that only the most current, approved procedures are in use while meeting ISO, FDA, OSHA, or internal standards with confidence.

As production needs evolve, your workforce must stay flexible. Dozuki supports that adaptability by delivering the latest procedures across any device, in the right language, and even when offline.

You can push updates instantly to keep teams aligned, responsive, and ready to meet changing demands.

Clear guidance is critical for complex jobs. Dozuki enhances every procedure with visuals, safety callouts, and interactive checks to help workers follow each step accurately.

By removing ambiguity, you reduce the risk of errors, rework, and safety incidents, supporting consistent performance at every level.

Tribal knowledge and legacy documents shouldn’t slow down your operations. With CreatorPro AI, you can record expert knowledge on video and instantly convert it into standardized procedures.

Dozuki helps you transform scattered knowledge into scalable, digital instructions that support job execution, training, and compliance from day one.

A leading chemicals manufacturer needed to preserve decades of critical know-how from a retiring workforce. Operators on the floor had deep expertise, but it was undocumented, inconsistent, and inaccessible to new hires.

With Dozuki, they rapidly transformed that tribal knowledge into visual, standardized work instructions. Armed with tablets and intuitive tools, their experts created digital guides across 100+ facilities, enabling faster onboarding and more consistent execution across every site.

With nine production sites and a diverse, multilingual workforce, Costa Farms needed a scalable way to deliver clear, up-to-date process guidance. Legacy SOPs were trapped in binders and PDFs, creating bottlenecks on the floor. Operators were forced to stop work and wait for clarification, delaying production and impacting quality.

By standardizing SOPs in Dozuki and deploying QR codes across the floor, Costa reduced SOP access time from 7.5 minutes to just 2.5. The team now manages updates with structured approvals, translates instantly for Spanish and Creole-speaking operators, and equips every worker with instant access to current standards.

“It took over 20 years to build our processes, Dozuki standardized it in just weeks.”

“Operators find answers 55% faster, right at the machine.”

“What took hours now takes 5–10 minutes with CreatorPro AI.”