Industry 4.0 Is Here, Are You Ready?

Historically, internal systems for work instructions have been used solely for distributing procedures, with entirely separate systems for data collection and reporting. These disconnected systems are holding companies back.

As the digital revolution continues to make information sharing easier than ever, industrial businesses are ready to reap the benefits. Enter: Industry 4.0.

Industry 4.0 empowers companies to create secure, controlled systems where digital devices and their human counterparts communicate seamlessly with one another. These next-gen production environments make processes visible and controllable from almost anywhere.

It might sound like a scene from a sci-fi movie, but there are no special effects at play here—it’s much more real and attainable than it seems. With minimal implementation, see how can you start benefitting from Industry 4.0 with Dozuki's newest features.

Real-time Process Control

Keeping work instructions and data collection in two separate systems made continuous improvement a challenge. Information had to be exported, imported, and analyzed—taking valuable time before being implemented.

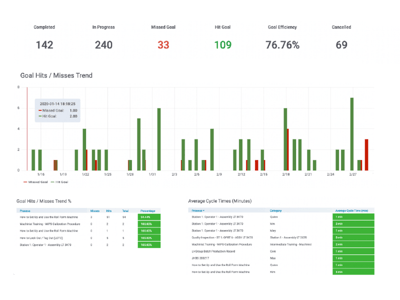

A clear, step-by-step display and unique data capture prompts ensure your users stay on track—every time. On your management side, dashboards give you instant feedback into how your processes are being followed by users.

Merge Data Collection and Reporting

Data gathered from disconnected paper and digital systems is only showing you part of the picture. How can your business continue to improve if it isn’t referencing up-to-date data?

Operator and Dashboard Views go beyond traditional work instructions and checklists to give you instant insights on timing, quality issues, sign-offs, and more.

Focus on the metrics that matter most to your goals, reporting dashboards are configurable, giving you the new ability to know exactly how teams are performing. This real-time intelligence lets you identify opportunities for growth and process improvements.

Written by Leslie Bloom

Related Posts

Blueprint for Brilliance: Takeaways for Joining the Ranks of the World’s Most Productive Companies

LNS Research recently released its 2025 Benchmarking the Journey of the World’s Most Productive Companies report, and the findings are a wake-up call for the industrial...

Continue ReadingThe Future of Manufacturing in 2026: Empowering the Connected Worker

Key Takeaways (The TL;DR) Connected worker initiatives will be central to driving efficiency, safety, and productivity in 2026. Manufacturing technology is advancing...

Continue ReadingWhy Workforce Agility Will Define 2026

In 2026, manufacturers won’t be judged solely by what they produce, but by how fast they can adapt. The year ahead brings a wide range of scenarios: cautious optimism...

Continue Reading