Why Do Value Stream Mapping? | Benefits & Examples

A successful business incorporates two critical factors, customers, and cost. The goal of any business is to provide the most outstanding value for the customer at the lowest price. Doing so maximizes profits while ensuring the customer remains happy and the company remains competitive.

Table of Contents

1. Key Concepts of Value Stream Mapping

3. Benefits of Value Stream Mapping

4. Challenges & Limitations of Value Stream Mapping

5. Steps in Implementing Value Stream Mapping

6. Tips for Effective Value Stream Mapping

7. Integrating VSM with Lean Manufacturing

8. Value Stream Mapping Tools & Software

Maximizing value while minimizing overhead is a balancing act for organizations, and it is the motivating factor behind most business activities. The manufacturing industry has put great effort into optimizing this equation over the past century.

Thanks to methodologies like Lean Manufacturing and Six Sigma, significant progress has been made in creating tools that help organizations identify and eliminate one of the biggest causes of unnecessary overhead while boosting productivity - waste.

One of the most valuable tools to accomplish this is value stream mapping.

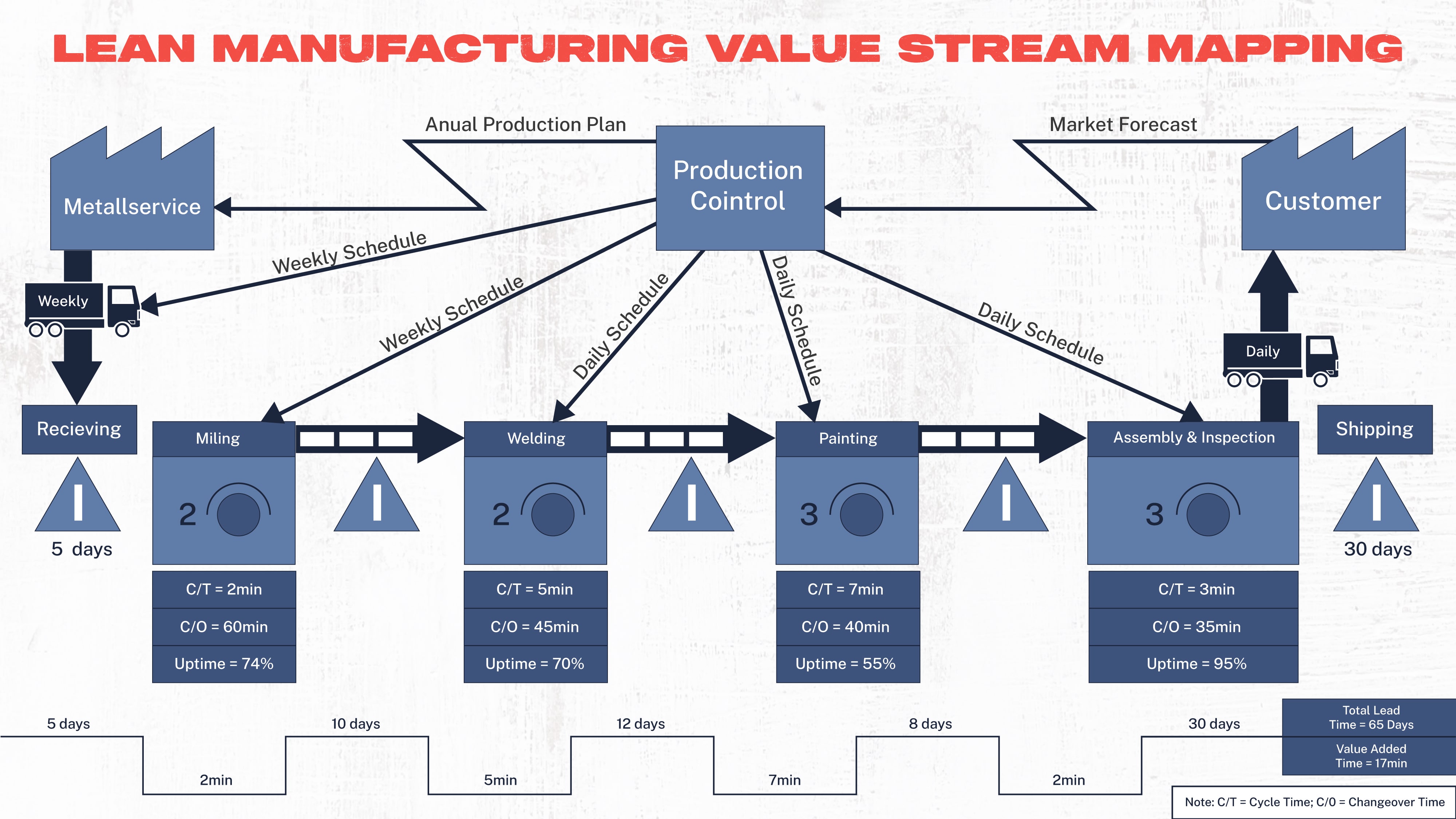

According to PwC, about 80-90% of typical business activities are wasteful and don’t add value for customers. Value stream mapping is a visual guide for delivering a product or service from start to finish It’s in a process; it’s easier to see which actions by displaying the steps in a process value.

The goal of value stream mapping is to maximize value and minimize waste.

Value stream mapping, or VSM, can help organizations reduce unnecessary waste by eliminating or lowering steps that do not add value to the customer. Doing so makes it possible to boost efficiency and productivity, reduce waste, and focus on optimizing every process for the customer's benefit.

This article will outline value stream mapping and how organizations can implement it successfully. Plus, we’ll look at some process mapping tools companies can use to make the job easier.

Key Concepts of Value Stream Mapping

Value Steam Mapping has been around since the early 1900s. Like many other modern lean manufacturing methods, its popularity can be traced to the Toyota Production System. This organization revolutionized the manufacturing industry by implementing lean manufacturing principles to remove waste from automated systems.

The Japanese call this waste “Muda,” which is a term that translates to “unnecessary.” In this application, Muda is any activity that does not add value to a product or service.

Value stream mapping attempts to differentiate value-adding activities from non-value-adding activities in a way that is easy to visualize. Let’s break down the definitions of these two terms.

Value-Adding Activities – A value-adding activity is anything that changes the form or function of a product or service in a way that a customer is willing to pay for. Necessary steps in the production process are value-adding activities, as is the required exchange of information.

Non-Value-Adding Activities – A non-value-adding activity does not add value to a product or service. If a step can be eliminated or the activity reduced without affecting the outcome for the customer, then that step does not add any value to the process.

These are the steps where waste in a process can hide. Identifying them helps organizations understand how they can be removed from a process safely without jeopardizing the outcome.

The True Cost of Muda

Waste can come in many different forms. Lean manufacturing has identified eight causes of waste, which comprise the acronym “DOWNTIME.”1 They are:

- Defective Production

- Overproduction

- Waiting

- Non-Used Employee Talent

- Transportation

- Inventory

- Motion

- Excessive Overprocessing

The actual cost of downtime is hard to calculate, and over 80% of companies say they cannot quantify it. However, it’s estimated that unplanned downtime can cost a company as much as $260,000 – per hour.

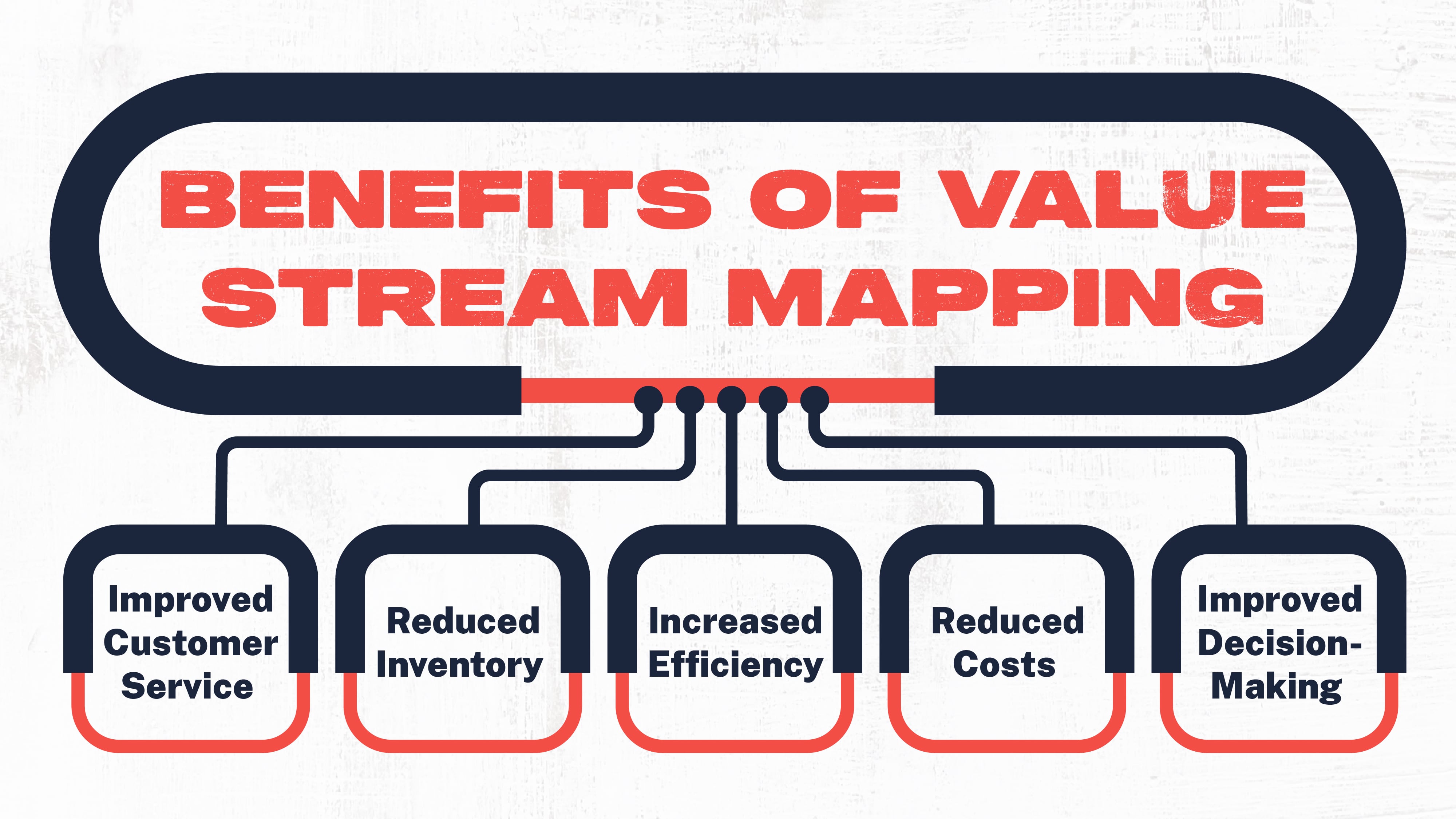

Benefits of Value Stream Mapping

Another high cost of waste is poor quality. Quality is one of the most important goals for manufacturers. It’s estimated that poor quality outcomes cost the average manufacturing company about 20% of its total sales revenue. Waste and quality are inseparable, leading to a higher quality product and greater customer value.

That’s just one benefit of value stream mapping. For manufacturing organizations, the benefits are many and include:

Improved Customer Service

The customer is at the heart of every business decision, or they should be. It follows that streamlining processes until every step adds value for the customer will increase that customer’s satisfaction. Companies can use VSM to improve the overall quality of their products and pass those benefits on to their customers.

Reduced Inventory

Excess inventory costs organizations money. It’s estimated that a business’ inventory carrying costs come close to 20-30% of its inventory value. Sufficient stock is essential, but carefully balancing inventory with demand can save organizations millions. VSM helps companies pinpoint and reduce causes of excess inventory.

Increased Efficiency

Removing non-value-adding tasks will increase the efficiency of a process. Reducing or eliminating unnecessary steps will help companies streamline processes and ensure they’re only putting time and effort into those steps that add value for the customer.

Reduced Costs

Eliminating waste saves organizations money. It’s as simple as that. VSM enables companies to identify steps in processes that are creating or hiding waste and strategize ways to remove it without changing the outcome of the process.

Improved Decision-Making

Value stream mapping is a tool – a means to an end. Using it effectively gives organizations more information regarding their processes and empowers them to make smarter decisions. It helps companies identify areas where improvements can be made and allows them to effectively strategize solutions for implementing those improvements.

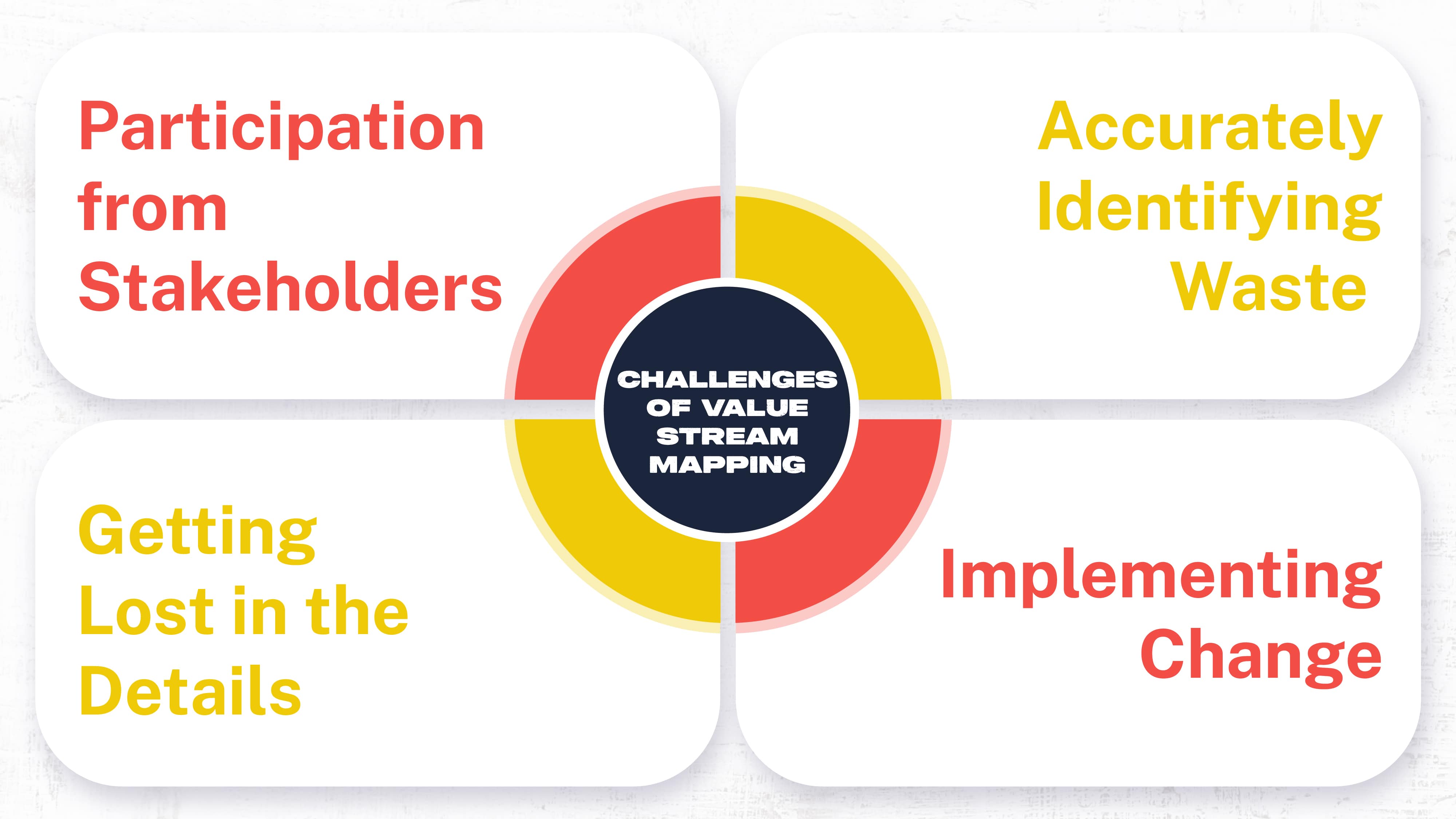

Challenges & Limitations of Value Stream Mapping

Value stream mapping can be highly beneficial for manufacturers if implemented effectively. But like anything, some pitfalls and challenges can reduce the value of this tool.

We’ve outlined some of these challenges and limitations below.

Participation from Stakeholders

Value stream mapping requires the participation of everyone involved in a particular process, sometimes even stakeholders. And as we all know, human beings are slightly resistant to change. It will take everyone working together, communicating effectively, and offering insights to make the tool work effectively.

When information is siloed in individual departments, it hampers the improvement process. Organizations must break down those silos to work correctly and bring employees, supervisors, designers, and stakeholders together with a common goal.

Accurately Identifying Waste

VSM is designed to help organizations identify non-value-adding steps in a particular process. Those steps can be considered waste because they don’t add value to the final product. But eliminating steps too eagerly can lead to a breakdown of other efforts.

Most process steps are interconnected. One relies on another or supports another in some way. Identifying which process parts are unnecessary and can be labeled as absolute waste, is delicate.

Getting Lost in the Details

Value Steam Mapping can be as simple as a marker and a whiteboard. Or it can involve hours spent virtually learning a new language of symbols and terms.

Depending on the complexity of an organization or a particular process, a more detailed approach may be necessary and beneficial. But getting lost circling the details can become a good use in and of itself if implemented correctly and efficiently.

Implementing Change

Like any tool, a VSM is a tool that serves a purpose. In this case, it’s used to identify waste, remove or reduce it, and then build a better process going forward. Organizations can sometimes get lost in the creation of the VSM itself and lose sight of the goal, which is to do more with less. Success hinges on the “doing” rather than the planning.

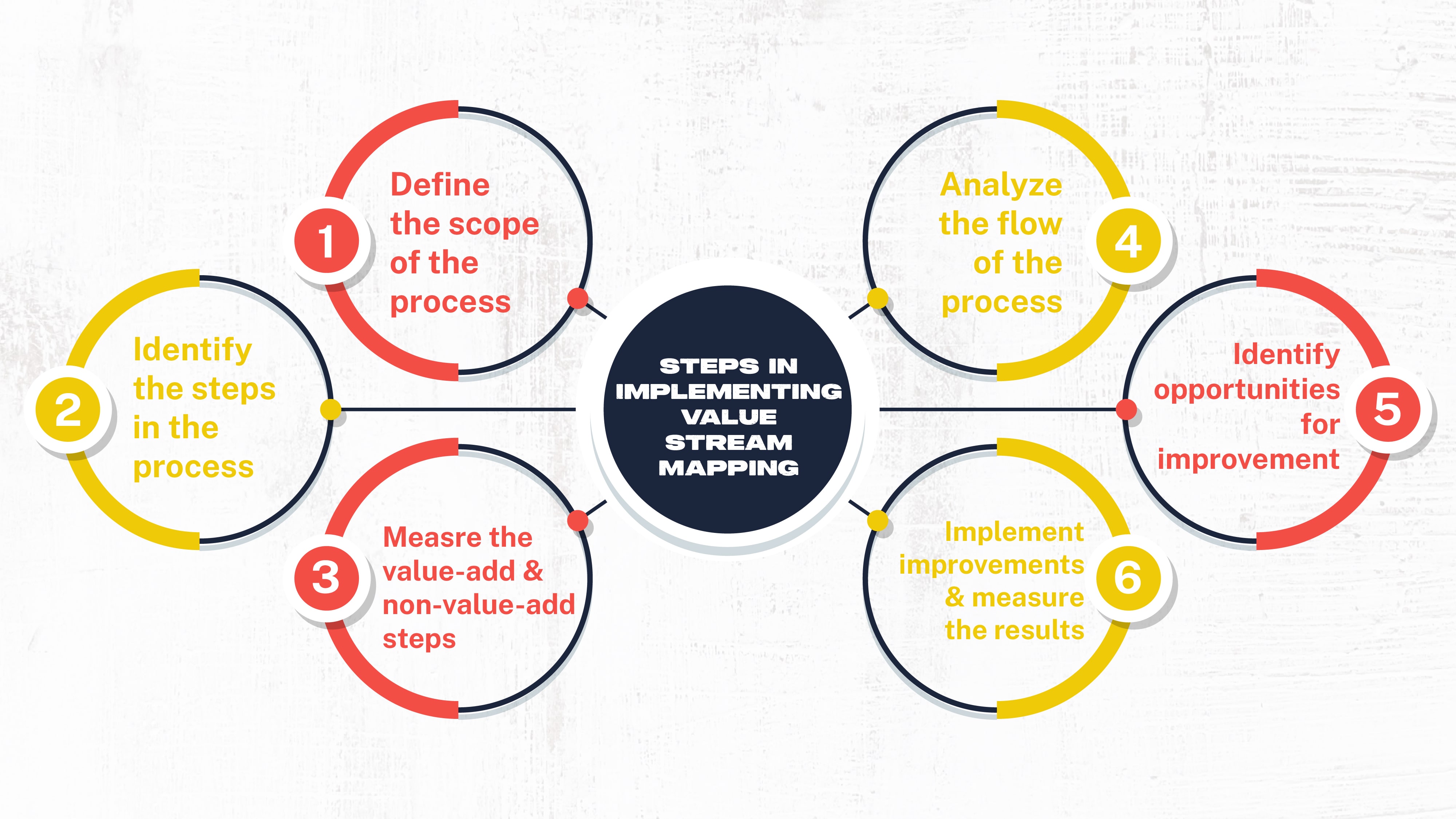

Steps in Implementing Value Stream Mapping

Value stream mapping involves creating two maps of a process – the current state map and the future state map. The current state map accurately depicts a process from start to finish.

The future state map is what an optimized process might look like. The goal is to pinpoint the differences between the two and brainstorm strategies that can help the team get there.

VSM is a multi-step process. For more straightforward implementation, we’ve outlined those steps here.

1. Define the scope of the process.

Every Value stream map needs an end goal. To create that goal, teams need to start by understanding what the process accomplishes and why optimizing it is beneficial.

In the case of manufacturing companies, the answer to these questions is often intuitive. A process is used to create a product, and the benefit of optimizing that process is a greater value for the customer at a lower cost for the company.

But it’s not always as cut and dry as that, and VSM can be applied in numerous ways and for many different reasons. Start by ensuring all team members have a clear understanding of both the why and how.

2. Identify the steps in the process.

A manufacturing process can have many individual steps or just a few. Understanding each step in the process and how they relate to or rely on one another is vital.

Start at the beginning and map each step as you go along, including the movement of information. Include every team member involved in the process and their roles and responsibilities in relation to the process.

3. Measure the value-add and non-value-add steps.

This step is what makes VSM so beneficial. Waste can sometimes be obvious and easy to spot at this stage. Or it might be hidden and harder to identify. Measure each step of the process in terms of how it adds value to the final product for the customer. Highlight steps that do not add value or more waste than they’re worth.

4. Analyze the flow of the process.

The flow of a process will determine how quickly and effectively it works. Analyzing the flow before removing steps will help team members understand which actions are expendable or unnecessary and which play a critical role in the overall flow of the process. It’s important not to hinder the flow of the process by removing steps that seem unnecessary but indeed aren’t.

Once non-value-adding activities are removed or reduced, it’s critical to re-analyze the process flow to ensure it still works as intended.

5. Identify opportunities for improvement.

Using the information from the first three steps, including identifying an end goal, mapping out actions, and targeting non-value-adding activities for removal or reduction, teams can start to strategize a better way forward.

6. Implement improvements and measure the results.

Each process is complete with testing and analysis. Once changes to a function are complete, measure the results and note what worked and what didn’t. This measurement is the only way to get better.

Tips for Effective Value Stream Mapping

Value stream mapping can be a handy tool that helps organizations visualize a process from end to end. This visualization lets teams see what’s happening along each step and where waste occurs more quickly. But getting it right can be tricky. Here are some of our best tips for success.

Choose the proper process to map.

Not every process requires a detailed value stream. To avoid creating waste in the process, target those that play the most prominent role and have the most significant effect on an organization.

This targeting is also vital because many manufacturing facility processes are interlinked. One leads to another, which leads to another.

Use a big-picture view to see which links in the chain have the most impact on the final product and would benefit the most from improvements. In other words, target processes will make all the work of VSM worth the effort.

Involve the right people.

A process usually involves multiple people working together for an end goal. When creating a VSM, include everyone who touches a process at both ends.

This includes workers and operators who create a product, managers, and supervisors who oversee a process, engineers, designers, developers who make the process, and suppliers and partners who support the process. Most importantly, consider the customer who benefits from the final product.

Be clear about the goal.

Setting a clearly defined goal before starting a Value Stream Map will ensure that all team members understand and are working toward that goal. And it will keep activities centered around accomplishing that goal. Don’t get lost in multitasking when creating a VSM. A targeted approach is much more effective.

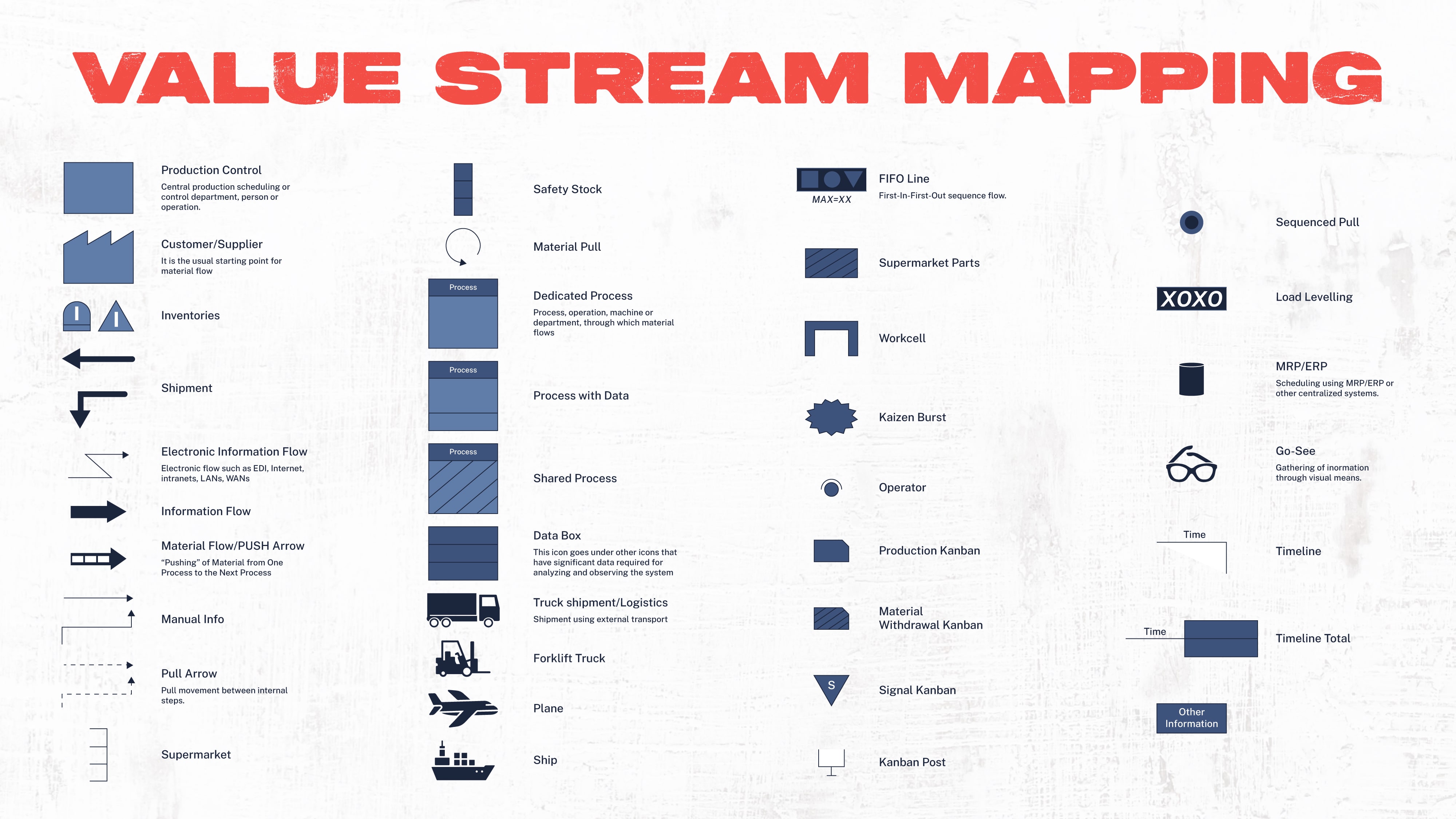

Use a consistent set of symbols.

Value stream maps often rely on symbols that demonstrate steps in a process and how they relate to one another. Using a consistent set of characters or language will make it easier for team members to understand the map and put it to use.

Include all steps in the process.

When creating a VSM, companies often omit steps from the process that seem "unimportant." But starting that way defeats the purpose of the VSM. Every step in the process should be included on the map, even those that are not value-added. That way, team members can see the entire scope of the problem.

Be realistic about change.

Strategizing and implementing improvements takes time, energy, and resources. Consider these factors when creating a VSM so everyone understands what’s at stake. And don’t expect to see changes overnight but be realistic about reaching the end goal.

Continue to monitor and adjust.

A VSM is not a one-and-done project. Companies should see it as an evolving organism. As Process changes and improvements are implemented, measure and analyze results. Update the VSM to reflect these results and continue to monitor and adjust over time.

Integrating VSM with Lean Manufacturing

Value stream mapping is a lean manufacturing technique organizations can use to analyze and visualize the flow of materials and information required to bring a product to a customer. Implementing a VSM aims to streamline a process to benefit the customer and the company.

Lean manufacturing is becoming the standard for manufacturing companies because of its incredible value. Instead of doing things the same way and getting the same results, lean manufacturing strives to do things better – to do more with less.

VSM is one tool under the umbrella of lean manufacturing that companies can use to meet this goal and reach that ideal of continuous improvement.

Reducing or eliminating waste of all kinds is the backbone of lean manufacturing principles. And it’s what drives lean manufacturing techniques, like VSM.

Eliminating unnecessary waste, from wasted materials, time, energy, or labor, can save organizations millions of dollars. Doing it effectively, without hindering the value for the customer, is the crux.

Value Stream Mapping Tools & Software

Value stream mapping can get very complicated quickly, depending on the size and scope of a process or the company itself. The good news is that several value stream mapping tools and software are available to simplify the task. Each program has its strengths and weaknesses, and each business will have unique needs.

Here are a few of the most popular value stream mapping tools and software programs on the market:

- Lucidchart

- EdrawMax

- Microsoft Visio

- SmartDraw

- Bizagi

Choosing a value stream mapping tool can take time and effort. You don’t want to overwhelm team members with unnecessary and over-complicated features. But you also don’t want to choose a tool that doesn't meet the requirements or complexity of a project. Answering the following questions can help narrow the choices:

What are the specific needs of the business?

What features are offered by the tool?

How much does the tool cost?

Is the tool easy to learn and use?

What kind of support does the vendor offer?

Match the Tool to the Needs of the Business

With so many choices, each one a bit different, knowing the most innovative investment can take time. Answering the key questions above will help eliminate tools that don’t fit an organization’s needs.

Ultimately, companies need to choose a tool that is within the budget, easy and intuitive for team members and offers features that will meet a company’s needs.

Final Thoughts

Value stream mapping is a valuable tool for businesses across many industries. It’s a vital component of a lean manufacturing culture for manufacturing companies. A VSM can help further the goal of creating more value for a customer and doing it at a lower cost for the company.

Identifying waste in the production process is the definition of lean manufacturing. Getting rid of that waste improves efficiency and effectiveness, reduces costs, and saves companies time and effort.

Many companies don’t even realize the amount of waste in a process. A VSM helps them visualize and pinpoint that waste and create a better process in the future.

By following the steps outlined in this article, businesses can use value stream mapping as an effective tool to improve their processes and achieve their goals. That goal should be to provide a high-quality and greater-value product for the customer.

Written by Dozuki

Related Posts

Blueprint for Brilliance: Takeaways for Joining the Ranks of the World’s Most Productive Companies

LNS Research recently released its 2025 Benchmarking the Journey of the World’s Most Productive Companies report, and the findings are a wake-up call for the industrial...

Continue ReadingThe Future of Manufacturing in 2026: Empowering the Connected Worker

Key Takeaways (The TL;DR) Connected worker initiatives will be central to driving efficiency, safety, and productivity in 2026. Manufacturing technology is advancing...

Continue ReadingWhy Workforce Agility Will Define 2026

In 2026, manufacturers won’t be judged solely by what they produce, but by how fast they can adapt. The year ahead brings a wide range of scenarios: cautious optimism...

Continue Reading