Optimizing Operations with Dozuki Connected Workers

The real barriers to production optimization aren't your people, they're the systems around them. Outdated processes, disconnected information, limited visibility, and the absence of real-time guidance leave frontline teams reactive and operations exposed.

As manufacturing complexity increases, these gaps stall throughput, drive up risk, and erode performance.

Dozuki helps manufacturers replace this fragmentation with system-driven control. Our Connected Worker platform unifies standard work, role-based training, operational execution, frontline feedback, and performance analytics.

This creates a real-time loop of operational excellence. With every guide followed, issue flagged, or skill earned, knowledge flows faster and execution gets stronger.

Digital Knowledge Management ensures centralized documentation and procedures are accessible from any device. Digital Learning Pathways deliver role-specific training with automated assignments and tracking. Digital Operational Workflows embed quality checks directly into production processes. Digital Performance Analytics provides real-time visibility into execution and compliance metrics. Each module builds quality into the daily habits of every worker, creating a comprehensive approach to error prevention that transforms how manufacturers operate.

The Hidden Costs of Operational Drift

An operator reaches for a binder during a changeover, follows a step that was updated last quarter, and loses 12 minutes correcting the mistake. Multiply that across three shifts, five lines, and a week of production, and you've missed your target by miles.

Operational inefficiencies often hide in plain sight, showing up as rework, missed quotas, or inconsistent results across shifts. But the root cause is rarely one bad actor or broken process. It's the quiet erosion of standards, the slow drift away from what's documented toward what's remembered.

Even experienced workers revert to tribal knowledge when they can't access accurate, up-to-date guidance. And without real-time visibility or feedback loops, that drift compounds silently until a line stops or a defect slips through.

"By using Dozuki to standardize work and improve processes, Johnsonville was able to reduce costs and achieve significant annual savings across lines."

— Learning & Development Director, Johnsonville Sausage

Dozuki customers have cut changeover times by 74%, reduced downtime by 40%, and increased throughput by 60%.

Eliminate Process Drift with Standardized Execution

Process drift isn't a training issue, it's a system failure. Even the most experienced operators deviate when procedures are outdated, unclear, or buried in binders. When teams rely on tribal knowledge, productivity, safety, and quality all suffer.

Waupaca Foundry saw a 300% increase in documentation usage and reduced safety incidents after digitizing core foundry SOPs. Southwire experienced a 24% drop in rework within 90 days by introducing Dozuki Operational Workflows (DOW) to wire assembly lines.

Dozuki Operational Workflows eliminate ambiguity by turning SOPs into interactive, step-by-step workflows. Each task includes required sign-offs, in-line media, and quality checkpoints. Logic rules adjust instructions based on shift, role, or product line, ensuring precision across variable conditions. Execution is tracked at the step level, giving supervisors visibility into what's happening, where, and by whom.

Dozuki is purpose-built to close these gaps. Our connected worker platform ensures that every procedure is up-to-date and accessible, every piece of feedback is tracked and acted upon, and every safety training is completed, logged, and verified. From the moment a concern is reported, Dozuki provides the structure and visibility to ensure it moves through the system until it’s resolved.

Balance Productivity Across Lines, Shifts, and Sites

Scaling production doesn't just mean increasing capacity, it means replicating success. But too often, what works on one line doesn't translate to the next. Documentation varies by site, updates lag, and local practices override standard ones.

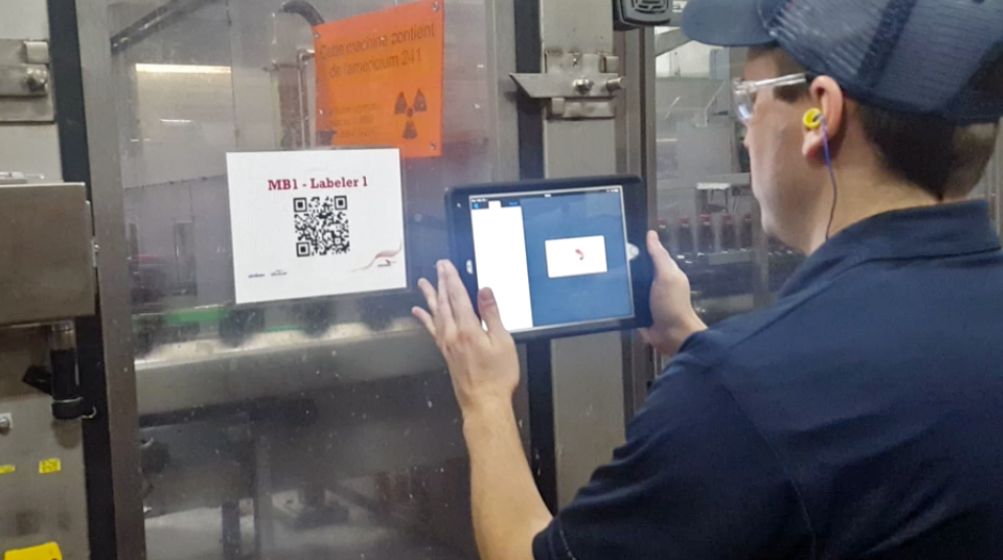

Dozuki Digital Knowledge Management (DKM) creates a centralized, version-controlled source of truth for all operational content. Each SOP is tied to a specific version, job role, and location. When procedures are updated, changes are instantly published, and tracked with automatic retraining assignments via Learning Pathways (DLP). Operators access only the latest approved version, at the point of use, via QR code or device.

QR codes placed directly at workstations provide immediate access to procedures in the user's native language. With support for over 100 languages, no worker is left guessing about safety procedures. Automatic notifications ensure workers acknowledge updates before continuing with procedures.

Re:Build Manufacturing unified multi-site operations with shared content modules, cutting onboarding time for new lines by 40%. Coast Aluminum replaced printed binders with QR-linked digital guides, reducing procedural errors by 37% across four plants.

Unlock Real-Time Visibility into Production Performance

Many manufacturers only realize something's wrong after it costs them—through missed targets, defects, or unbalanced workloads. That's because most systems rely on lagging indicators and anecdotal reports, not live floor data.

Dozuki Performance AI Analytics (DPAA) makes frontline performance visible in real time. Every step completed in Dozuki is timestamped, role-validated, and linked to specific work content. Supervisors can monitor live task completion rates, compliance gaps, and operator bottlenecks—across teams, lines, and shifts.

In the food and beverage industry, Dozuki analytics identified unseen slowdowns in quality checks. After allocating responsibilities based on step-level data, they improved line efficiency by 12%. One chemical customer used execution data to pinpoint inconsistencies in batching. After rebalancing tasks based on Dozuki insights, they increased daily throughput by 20% without adding labor.

Empower Frontline Teams to Drive Improvements

No optimization initiative succeeds without operator buy-in. Workers are the first to see when a step doesn't work, a tool is missing, or a shortcut becomes standard. But without a structured way to capture that insight, valuable improvements get lost, or never surface at all.

Dozuki Worker Collaboration (DWC) embeds frontline feedback directly into daily workflows. Operators can flag unclear instructions, annotate steps, or suggest SOP changes from any device without leaving their station. Submissions are routed to the appropriate SME or approver. Once approved, version updates go live, retraining is triggered, and the new standard becomes part of everyday execution.

In aerospace, structured feedback loops allowed operator suggestions to drive SOP changes. Improvements are now traceable and proof of continuous improvements, enabling confident ISO audits. A biomedical packaging customer used DWC to revise seal integrity checks that were failing visual inspection. First pass inspection rates rose by over 22% after updating unclear criteria based on operator feedback.

Build a Self-Sustaining Optimization Loop

Most optimization efforts stall because they rely on memory, meetings, or manual updates. Improvements may happen, but without a system to reinforce, track, and scale them, momentum fades and old habits return.

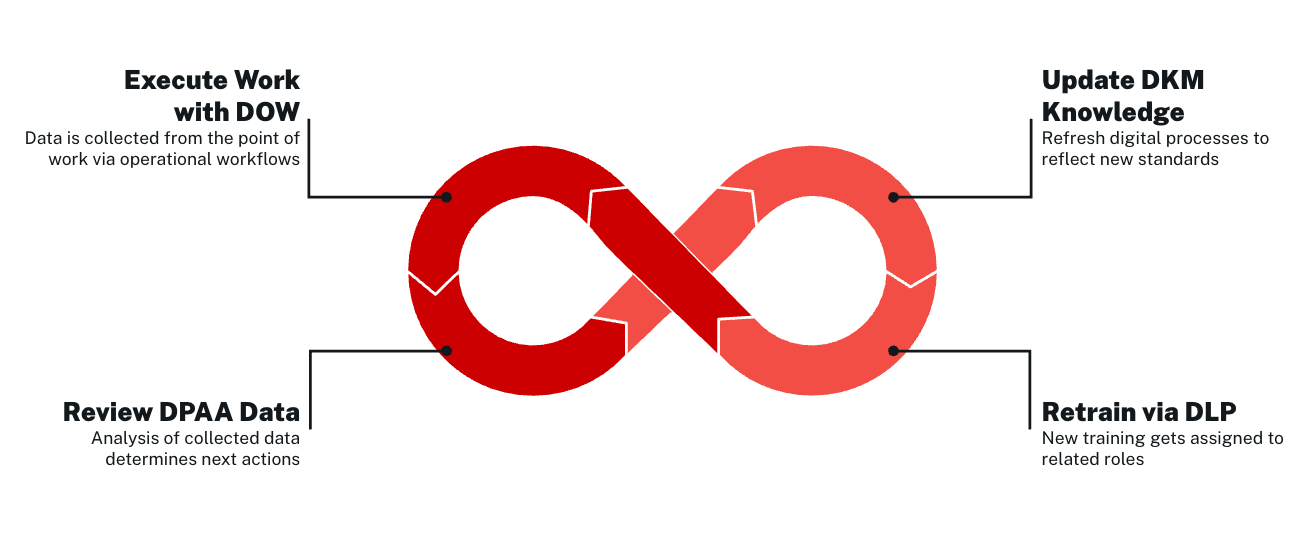

Dozuki solves this by creating a self-sustaining improvement loop. It begins with data from DPAA or audits, which triggers changes in DKM. These updates then assign retraining via DLP. Execution is enforced with DOW, and operator feedback is collected through DWC, which feeds new ideas back into the cycle. It's a continuous feedback loop where frontline insight becomes operational excellence.

Dozuki turns feedback into a live improvement mechanism, one that your team can proactively manage and one that builds up a culture of continuous improvement throughout operations.

FNA Group reduced downtime from procedural errors by 50% and kept training compliance above 95% across three sites. An energy sector customer embedded QA gates directly into production workflows. Audit prep time dropped from two days to five minutes, while quality issues were caught in real time.

Performance Is a System Choice

Optimizing production doesn't come from pushing harder, it comes from designing smarter. The manufacturers who outperform their peers aren't relying on tribal knowledge, siloed systems, or clipboard audits. They're using connected platforms that embed performance into every process.

Dozuki unifies standards, training, execution, and feedback into one system. That system doesn't just inform workers, it empowers them. It doesn't just document procedures, it drives accountability. And it doesn't just flag problems, it fixes them at the source.

From aerospace to building materials, from food and beverage to packaging and metal fabrication, leaders are proving that operational excellence is possible. Not by hoping for fewer mistakes, but by designing systems that make them harder to occur.

Ready to optimize your production operations? Learn how the Dozuki Connected Worker Platform can transform your manufacturing performance with measurable results across changeover times, downtime reduction, and throughput increases.

Frequent Asked Questions (FAQ)

What is a Connected Worker Platform?

A Connected Worker Platform is a system that digitally links frontline employees with the knowledge, tools, and processes they need to perform their jobs effectively. It replaces outdated documentation, fragmented training systems, and isolated quality controls with an integrated digital environment. For Dozuki, this means unifying standard work, role-based training, operational workflows, real-time analytics, and frontline feedback into a single platform.

How does Dozuki differ from a traditional LMS or document management system?

Traditional LMS platforms focus on passive learning events and are often divorced from real-world execution. Document systems are static repositories that lack control over how, when, or where information is accessed. Dozuki goes beyond both. It transforms knowledge into active, embedded workflows. Learning, execution, and feedback are tied directly to live production environments—ensuring that the right knowledge reaches the right worker at the moment of need.

How can Dozuki help eliminate process drift?

Process drift occurs when operators rely on tribal knowledge or outdated procedures. Dozuki solves this by embedding digital SOPs directly into daily workflows. With QR-code access, step validation, and role-specific instructions, workers follow the most current standard—automatically. When procedures change, updates are pushed live and retraining is triggered immediately, ensuring operational consistency across shifts, lines, and locations.

Can Dozuki scale across multiple facilities or business units?

Yes. Dozuki is designed for enterprise-wide standardization. All operational content is governed through version-controlled modules that can be shared, localized, and scaled across facilities. Whether you're managing 3 plants or 300, updates and feedback are coordinated through structured workflows that ensure compliance without chaos.

What kind of ROI can we expect from implementing Dozuki?

Customers typically see measurable results within 60–90 days. Reported gains include: 74% reductions in changeover times, 40% downtime reduction, 60% throughput improvement, and significant quality improvements. Companies like Waupaca Foundry, Southwire, Re:Build Manufacturing, and Johnsonville Sausage have documented both cost savings and operational resilience after implementing Dozuki.

How does Dozuki handle training compliance and skill validation?

Training content is tied directly to SOPs. When a procedure is updated, affected roles are automatically assigned retraining. Workers must demonstrate comprehension through quizzes and proficiency through supervisor sign-offs. All training events are logged for traceability and compliance audits. This eliminates gaps between what’s trained and what’s performed on the floor.

How does Dozuki enable frontline feedback?

Operators can flag unclear steps, suggest edits, or report issues directly within the workflow. Submissions are automatically routed to relevant SMEs or safety leads. Once reviewed and approved, changes trigger content updates and retraining. This creates a closed feedback loop where frontline input drives continuous improvement—not after the fact, but as part of daily operations.

Is Dozuki customizable to our specific workflows and compliance standards?

Absolutely. Dozuki supports logic-based workflows tailored by role, location, product type, or equipment. Whether you’re following ISO, OSHA, GMP, or internal protocols, the system can be configured to support your specific compliance, audit, and safety frameworks. Templates and form fields are fully customizable, and integrations with MES, LMS, and HRIS systems ensure seamless data flow.

Does Dozuki support multilingual teams and global operations?

Yes. Dozuki supports over 100 languages with machine translation, customizable glossaries, and change-aware content delivery. This ensures that every worker—regardless of location or language—gets access to the most current, accurate, and understandable information needed to execute their role safely and effectively.

How fast can we implement Dozuki?

Implementation depends on scale, but many manufacturers begin rolling out in as little as 30–60 days. Dozuki provides digital transformation support, onboarding guidance, and customer success resources to accelerate deployment. Most customers begin by targeting high-impact workflows or pilot facilities, then scale horizontally across sites.

Written by Scott Ginsberg

Related Posts

The New Playbook for Operational Learning and Development

How Dozuki empowers training leaders to close skills gaps, accelerate onboarding, and enforce standard work at scale. Training is No Longer a Department, It's a System ...

Continue Reading →Rethinking MES in the Era of the Connected Workforce

Most Manufacturing Execution Systems (MES) were built to rigidly enforce processes, not to empower people or evolve how work gets done. MES platforms excel at orchestrating...

Continue Reading →Dozuki Announces Record Breaking 2025

Dozuki in 2025: Cementing Global Leadership in the Connected Worker Category Dozuki, the pioneer of the Connected Worker Platform since 2011, today announced its most...

Continue Reading →