Frontline Of The Future, Part 4

According to recent numbers from the Bureau of Labor, there are 12,559,000 manufacturing employees in the country.

That’s eight percent of our nation’s employment.

And yet, it’s still hard to retain those workers. Particularly for companies who aren’t pursuing digital transformation goals. Manufacturers often lose promising new workers because of poor training.

Human resources managers in nearly every industry have heard or seen firsthand horror stories of new employees coming to work on their first day, but not coming back from lunch. Mostly because they didn’t receive proper, or even any training.

Thus far in our curriculum, we covered manufacturing history, process and accessibility.

Now it’s time to talk about the great force multiplier, training.

Operators will be sent to the floor with no experience or skills, make an embarrassing or expensive mistake, feel disempowered and not return to the line after lunch. It’s heartbreaking, and the workers aren’t to blame.

Here’s an example from an agricultural manufacturer, whose former frontline employee left an illuminating review:

“They expect you to learn so much, but it's very confusing. It’s not clear on what management wants you to learn, and everything is a treasure hunt to get skill blocks done. Working here is not worth it. High turn out rate. I've seen ten operators quit in the last year.”

Now, many manufacturers offer job shadowing and classroom training, which is better than nothing. But competency based on time spent watching other people work isn’t enough. And manually tracking with a paper based checklist is a recipe for human error.

Do you have a standard role based training process?

And a standard evaluation of competency?

Or is your training support limited to, “Just go ask Roger, he knows everything"?

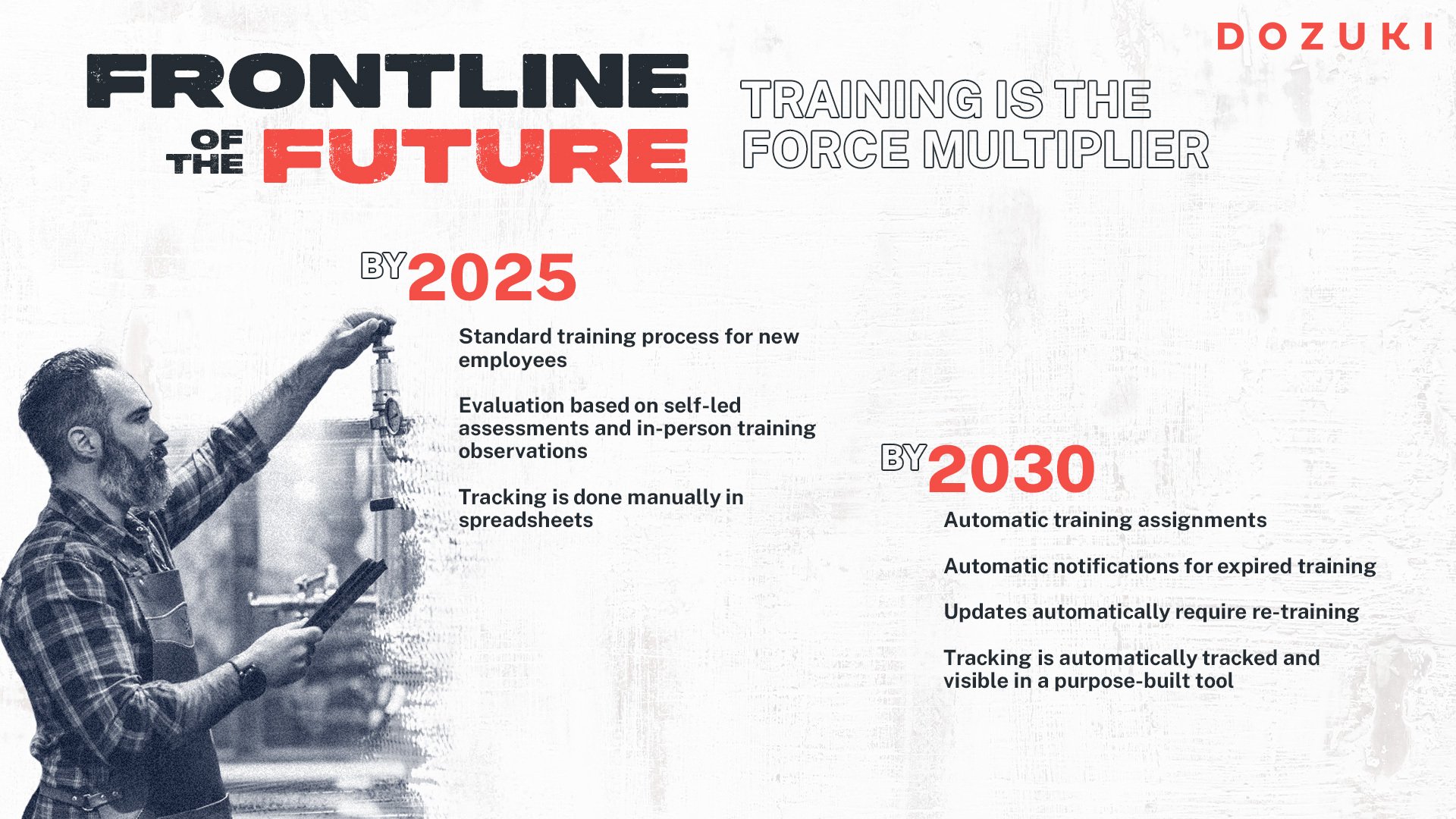

As we shed outdated, analog methods of frontline training, here’s what we foresee:

To create the frontline of the future, here are our training recommendations:

1. Move beyond traditional shadowing to robust education.

Most facilities we speak to offer job shadowing as their training. Which is an instructive and inspiring experience if a worker loves what they do. But not everyone does. Some operators take shortcuts and end up training the next generation of frontline workers to do the same.

Dozuki built our Courses product for this very reason. Once a company has documented their standards, we help you to turn that into the training curriculum. First, your operators do a “read and agree,” to make sure they understand the big picture. But then we also incorporate quiz modules.

Now you can see if your frontline workers actually understand what they have been trained on. That’s not training, it’s education. It’s more than process information, it’s a professional inheritance.

2. Trigger retraining in real time.

Dozuki also helps you automate the retraining of anyone on your team. When a particular standard is updated, whoever trained on that version will be signed up for a retraining. Our software triggers this within the platform, ensuring people aren’t outdated in their learnings, so as to avoid safety risks.

What’s more, our training centers around certifications like ISO compliance. When auditors eventually walk around your factory floor, and they ask, “When was the last time you were trained on this?” workers no longer have to guess.

The training log proves that training matches with the current standards. Triggering retraining ensures you’re always up to compliance and satisfying due diligence.

3. Approach competency holistically.

There are numerous ways to grade frontline workers to show how competent they are in a given process. If you’re planning on using a connected worker solution for your frontline, ensure there are tools to get an overview on team competency.

This is a lifesaver when there are absences, workforce changes or other team challenges. If you’re disciplined in updating people’s evolving skill sets and compatibilities, the right digital solution can be your best workforce planning tool. Now you’ll know exactly who’s trained on what, and how well, so they can jump in to solve important problems.

- - -

To wrap up this lesson on training, here’s an insight from one of our customers. We spoke with the Director of Supply Chain Finance at a food manufacturer recently, and her comment summarized it perfectly:

“Training is one of the most fundamental building blocks for doing everything else well in our plants. A well trained maintenance staff is going to reduce downtime event frequencies and also the time each one lasts for as an example.

Well trained lab techs will ensure that they follow standard lab testing methods all the time and their equipment is calibrated. And well trained logistics employees will pick and pull loads faster and more efficiently reducing unnecessary overtime and frustration.”

If you want to optimize your workforce with expert knowledge delivered through simple, accessible and engaging training programs, you’re come to the right place.

By following the above recommendations, your team will capture and standardize knowledge to easily distribute it across your workforce. Building simple and engaging training programs so everyone has the same guidance.

The result is faster, safer, and better manufacturing.

Read Part 5 next!

Written by Lucas Bishop

Related Posts

Blueprint for Brilliance: Takeaways for Joining the Ranks of the World’s Most Productive Companies

LNS Research recently released its 2025 Benchmarking the Journey of the World’s Most Productive Companies report, and the findings are a wake-up call for the industrial...

Continue ReadingThe Future of Manufacturing in 2026: Empowering the Connected Worker

Key Takeaways (The TL;DR) Connected worker initiatives will be central to driving efficiency, safety, and productivity in 2026. Manufacturing technology is advancing...

Continue ReadingWhy Workforce Agility Will Define 2026

In 2026, manufacturers won’t be judged solely by what they produce, but by how fast they can adapt. The year ahead brings a wide range of scenarios: cautious optimism...

Continue Reading