Improve Performance

Grow more efficient as you digitize and scale knowledge with Dozuki.

Reduction

in employee turnover rate

Faster

time to competency

Reduction

in changeover time

Reduction

in knowledge capture time

Partnering for Success

More than 600 companies in 38 countries have partnered with us on their frontline digital transformation journey. Join us.

“

The Dozuki connected worker solution is on track to save millions of dollars on just one of our lines this year. It’s a game changer.”

“

In just one year with Dozuki, we reduced employee turnover by 50%.”

“

Dozuki helped us fix a culture of information that was not current or standard across sites.”

“

After comparing Dozuki to other options, it became a clear choice. The system is so intuitive and easy to kick-off... just like navigating a website.”

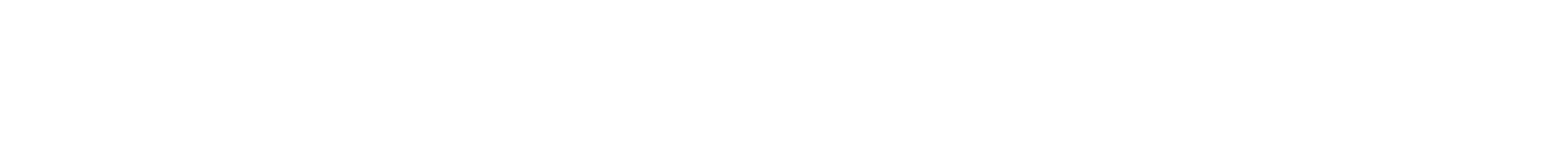

1 The Dozuki Process

Digitize Process Knowledge

-

Easily capture expert knowledge with photos and videos

-

Track, approve, and release documented procedures

-

Choose from more than 100 languages in one click

“

We’ve never trained people this quickly. New employees are becoming certified operators almost immediately instead of waiting a full year.”

See the Dozuki Difference

We help you capture and standardize knowledge to easily distribute it across your workforce, building simple and engaging training programs so everyone has the same guidance. The result is faster, safer, and better manufacturing.

Connected Work Instructions

Create standardized, audit-ready procedures that are easy to author and quick to implement.

Go

Operational Training

Distribute accurate knowledge across your workforce and track training progress, all from a tablet.

Go

Continuous Improvement

Capture insights straight from the floor to assess performance and discover opportunities for improvement.

Go

Transformation Services

Lean on our expert team to create an implementation plan, run change management, and help you deploy.

Go