Benefits of Practicing Food Manufacturing Hygiene

Prevention of Public Health Risks

The biggest win for companies who maintain good food hygiene practices is that they won’t make people ill as a result of their processes and products. Public health and safety should be important to companies across all spectrums, and food processing plants have a high bar of responsibility.

Increased Customer Loyalty and Satisfaction

When customers consistently receive safe, high-quality products from a company it builds brand loyalty. When public health and safety are at risk, even the slightest compliance issue can lead to a mass outbreak.

Companies that limit issues related to food safety and the transmission of foodborne illnesses will have happier, more satisfied customers, leading to an increase in customer loyalty.

Improved Reputation

Companies that have a solid record of maintaining quality standards will be better able to build a positive reputation with the public. Creating a public image that is synonymous with safe food products is easier to maintain when companies actively work to limit foodborne illnesses and diseases related to their products.

Job Security for Employees

Employees who work for a company that takes care and pride in their processes will have better job security. Outbreaks of foodborne illness can lead to facility shutdowns and even company closures.

But when risks are limited, employees won’t need to worry about issues leading to a possible layoff or job loss.

Lowered Turnover

Employees who work for organizations that put a high focus on health and safety standards are more likely to stay with that employer instead of seeking work elsewhere. A lack of concern for quality and safety controls often reflects a bigger issue related to company culture, and poor morale in the workforce will lead to higher turnover.

Lowered Risk of Litigation

Companies that fail to maintain food hygiene standards are at high risk for potential litigation. If food contamination leads to illness or death, companies can face lawsuits from affected consumers that can carry an extremely high price tag.

The effect of possible litigation will also have a major negative impact on customer loyalty and company reputation.

Prevention of Costly Fines

Many government bodies are responsible for ensuring organizations are doing everything possible to prevent food contamination and foodborne illness.

When companies fail health inspections and audits it can result in costly fines and even temporary shut-downs of production until critical issues are rectified.

Lower Food and Product Waste

Poor quality control and hygiene standards will inevitably lead to product wastage. Not maintaining proper food storage processes, temperature, and inventory control procedures will lead to food spoiling and lead to increase waste.

Higher Profits and Revenue

Companies that focus on maintaining high food hygiene standards and implement food safety systems effectively will reap higher profits. Every other benefit on this list will lead to an overall increase in revenue and profit for a company.

Cons of Not Maintaining Food Manufacturing Hygiene

Food hygiene standards and safety systems are important for food manufacturing companies for many reasons. Companies that do a good job maintaining safe procedures will benefit, and companies that fail to do so face severe disadvantages.

Issues related to the production or distribution of food products that lead to outbreaks of foodborne illness can destroy a company’s reputation in a matter of hours.

Disadvantages of not maintaining food hygiene standards include:

Risk of Allergic Reaction

Cross-contamination of food products containing allergens can pose a substantial health risk for individuals who have a sensitivity to these foods. There are regulations in place that require specific labeling of products manufactured in facilities where food products may elicit an allergic response, such as peanuts or tree nuts.

Risk of Food Poisoning

Food poisoning can mean many things and can be attributed to many causes, including contamination, poor temperature and storage procedures, and improper food manufacturing hygiene standards.

Companies that fail to maintain standards in all areas increase their risk of passing contaminated food products to consumers, which can result in food poisoning with the possibility of causing widespread, severe illness and even death.

High Product Recalls

Companies that fail to execute food safety practices face the risk of product recalls related to possible contamination. If an outbreak occurs, a product is mislabeled, or presents a public health risk, it could lead to a recall.

This causes a financial loss for companies that must issue refunds for products and can be a major blow to the company's reputation, as product recalls are highly publicized as a public health threat.

In 2021 alone, there were 38 recalls issued in the U.S. for a total of over 14,486,371 pounds of product.

Lowered Profits and Company Reputation

Recalls, facility shutdowns, and lowered customer confidence all lead to lowered profits for companies. Companies that don't maintain proper food hygiene standards put their profit margins at risk and endanger customer relationships.

Once news gets out about an outbreak or possible contamination, it destroys the public trust and companies may face huge hurdles trying to rebuild consumer confidence.

Higher Cost of Business

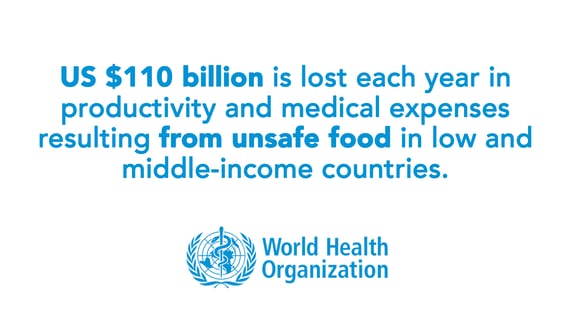

The cost of doing business will increase greatly if the risk of foodborne illness is not controlled within manufacturing facilities. Companies that put public safety at risk increase their chances of being sued by consumers and face possible prosecution related to the adverse effects of their actions.

In addition to that, companies that receive multiple violations or have numerous issues related to the safety of their products will most likely have to pay higher insurance premiums.

Illnesses Caused By Poor Food Manufacturing Hygiene

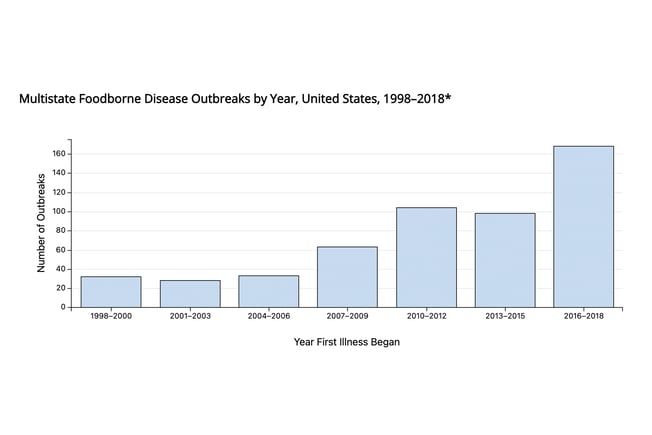

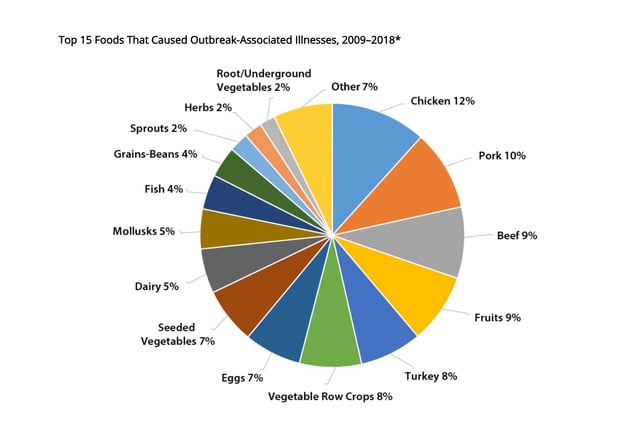

According to the CDC, there are over 250 foodborne diseases. They mostly include infections caused by bacteria, viruses, and parasites. Harmful toxins and chemicals can also contaminate food and cause illness. That’s why it’s so important for companies to maintain high food manufacturing hygiene standards.

Below is a list of some common and often most deadly foodborne illnesses:

E. Coli (Escherichia coli)

-

E. coli includes several species of bacteria, some of which may cause mild illness with symptoms of stomach upset and diarrhea. But other strains can cause severe illness including severe stomach cramps, vomiting, and bloody diarrhea.

-

E. Coli infections usually stem from contaminated food or water. Raw vegetables and undercooked beef products carry an especially high risk. Typical infections last from a few days to a week, but young children and elderly individuals have a high susceptibility to developing life-threatening kidney failure as a result.

Salmonellosis

Salmonella infection usually results from consuming raw or undercooked meat, poultry, eggs, and egg products. It can also result from unpasteurized dairy products or contaminated fruits and vegetables. Cross-contamination is a common cause of salmonella infection.

Salmonella enters the digestive system when contaminated food or beverage is consumed and can lead to diarrhea, stomach cramps, fever, and vomiting. Young children, susceptible or immuno-compromised individuals may suffer from severe illnesses resulting in death.

Hepatitis A

The hepatitis A virus causes a form of hepatitis that can result in severe liver infection and is highly contagious. It is most often transmitted to humans from contaminated food or water, or close contact with an infected person. It can cause nausea, vomiting, and abdominal pain near the liver.

The Hepatitis A virus is often found in raw shellfish or water contaminated with raw sewage. And while most cases will resolve on their own, individuals with chronic liver disease and older adults are at an increased risk for acute liver failure. Its high transmissibility rate makes it a cause for concern in food manufacturing plants.

Campylobacteriosis

Campylobacteriosis is caused by several species of bacteria often found in raw or undercooked meat, especially poultry. It can also result from contaminated produce and untreated water. Symptoms usually include fever, abdominal cramps, and diarrhea. The CDC estimates that campylobacter bacteria is the number one cause of bacterial diarrheal illness in the United States.

Gastroenteritis

Often referred to as the stomach flu, gastroenteritis is a highly contagious viral infection that can be transmitted through contaminated food or water sources. Because of the similarity in symptoms, it can be easily confused with other similar infections caused by bacteria.

Infants, the elderly, and those with compromised immune systems are more susceptible to serious symptoms that can even result in death.

Staphylococcus Aureus

Staphylococcus aureus bacteria can create toxins that cause gastrointestinal illness if allowed to come in contact with food sources. While most humans and animals have a percentage of staph bacteria living naturally on their skin, when it is transferred to a food product that is not kept at an appropriate temperature or undercooked, it can multiply and lead to illness if consumed.

Listeriosis

Another serious infection caused by bacteria, listeriosis results in an average of 1,600 illnesses and 260 deaths every year. Most at risk are pregnant women, newborns, the elderly, and immunocompromised individuals. Severe illness can lead to infections of the bloodstream or brain.

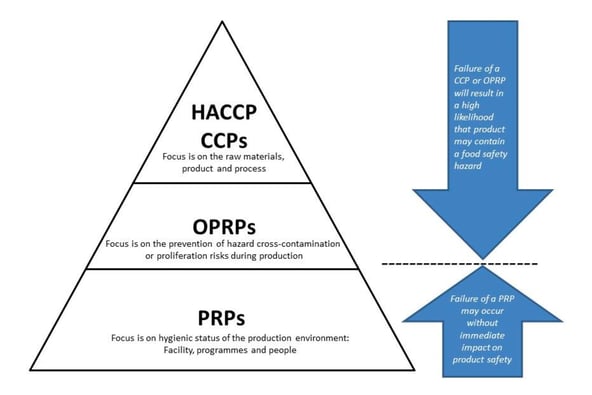

Best Manufacturing Practices To Maintain Good Food Hygiene

So what are the steps that food manufacturing facilities need to take to lower their risk of causing foodborne illness? Good food safety systems are a necessity at any facility that handles food or beverage products and must be implemented, monitored, and documented at every level of production.

So what are the steps that food manufacturing facilities need to take to lower their risk of causing foodborne illness? Good food safety systems are a necessity at any facility that handles food or beverage products and must be implemented, monitored, and documented at every level of production.

Here are some standards that companies must follow to maintain food manufacturing hygiene standards:

Cleaning and Sanitizing of Surfaces

Processing tools, equipment, floors, and surfaces should be cleaned and disinfected regularly.

Source Water

Because source water is a major cause of the introduction of contamination into food manufacturing plants, companies need to ensure that source water or recycled water is properly treated.

Waste and Sewage

Manufacturing facilities must have systems in place to properly handle the storage or disposal of wastewater and sewage.

Product Packaging

Systems should be in place to eliminate contamination during packaging processes.

Product Storage

Any storage facility or container used for raw or finished food products must be cleaned and disinfected regularly. Food product inventory should be maintained using FIFO (first in, first out) to ensure proper rotation.

Pest Control

Facilities must ensure that pest control measures are in place to prevent contamination of products or surfaces.

Proper Holding And Preparation Temperature

Follow standards for maintaining the proper temperature for food storage and preparation. Cold foods should be kept below 41 degrees Fahrenheit. Hot foods should be at 140 degrees Fahrenheit or above. Do not allow temperature-sensitive foods to stay above or below standards for more than two hours to prevent bacterial growth.

Transportation and Delivery

Any means of transport should ensure that food products are not contaminated in transit and that proper temperature is maintained to prevent spoilage and bacterial growth.

Preventative Measures

Companies should include the use of self-closing doors, foot or knee-activated faucets on hand washing stations, and liquid soap dispensers to reduce the surfaces employees need to touch regularly.

Sanitizing High Touch Areas

Doorknobs, elevator buttons, handrails, and equipment cart handles are all surfaces that employees must touch daily. Sanitizing these high-touch areas is vital to limiting the number of bacterium and viral matter to avoid contamination.

Hand Washing

One of the most important measures employees can take to reduce the transmission of contaminates is washing their hands correctly. Wash hands thoroughly with warm water and soap for at least twenty seconds. Hand washing should be done as often as necessary, especially when employees come in contact with surfaces that could be contaminated.

Proper PPE

All employees involved in food production processes or even present on the plant floor should be wearing proper sanitary protective clothing. This includes things like hairnets, gloves, shoe covers, and masks.

Food Sanitization Procedures

Certain raw food products, like fruits and vegetables, must be washed and cleaned thoroughly. Take care to wash meat, eggs, and seafood separately.

Prevention of Cross-Contamination

Keeping food preparation separate is the best way to prevent cross-contamination. Utensils, cutting boards, and surfaces used for meat, poultry, and seafood should be kept separate.

Employee Health

Employees who are feeling ill, especially with symptoms related to gastrointestinal issues, fever, or vomiting should stay home to prevent the transmission of disease.

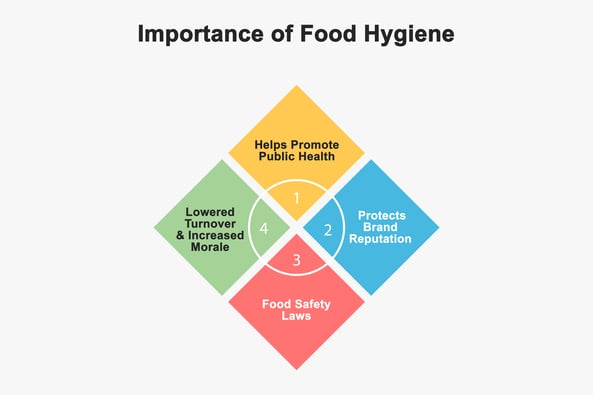

Why It’s Important to Train For Food Hygiene

Helps Promote Public Health

Having properly trained employees prevents costly mistakes that can lead to the transmission of foodborne illness and cause a risk to public health. Not only does upholding proper food safety and hygiene standards help prevent customers from getting sick, but it protects the company from litigation and possible legal recourse.

Protects Brand Reputation

Employees who are knowledgeable and trained in food safety practices will be better able to protect a company's brand and reputation by producing safe, quality products. Fewer mistakes and oversights lead to fewer customer complaints, a lowered risk of damaging product recalls, and overall happier, more satisfied customers.

Food Safety Laws

There are certain laws and regulations in place designed to uphold food manufacturing facilities to the highest standard of food safety and hygiene standards. This helps to lower the risk of foodborne illness from contaminated food products and protect the overall health of consumers.

For this reason, it becomes even more important for companies to focus time and energy on proper training programs for employees. Food hygiene training gives employees the skills and knowledge to properly handle, store, and prepare food products. It also educates them on proper cleaning and disinfecting techniques and underlines the importance of personal hygiene practices.

Lowered Turnover and Increased Morale

It's proven that when employees are allowed to train effectively for their jobs, there are happier and more engaged. Proper training will also lead to an increase in efficiency and productivity, which is a benefit for a company’s bottom line.

Employees want to work for a company that puts a high level of importance on promoting quality control and safety measures and provides employees with the training they need to be successful. This will result in increased employee retention and an overall more positive workplace culture.

Carlos P., Director of Continuous Improvement, Costa Farms: “Operators find answers 55% faster, right at the machine.”

Drainage Systems and Pest Control

One of the biggest risks companies face in food production facilities comes from poor drainage control systems and the threat of invasive pests. Both scenarios can result in an increased risk of contamination of facilities and products. To maintain food manufacturing hygiene standards, companies must adhere to strict guidelines involved in managing both of these issues.

Drainage Systems

Wastewater and sewage are often a source of foodborne illness infection. Listeria is a common and sometimes deadly bacteria found in wastewater, and 70% of positive listeria screens are found in facilities' drainage systems.

That’s why it’s so important for companies to maintain cleaning and sanitizing procedures and equipment standards related to their drainage system. Drains must be thoroughly cleaned and disinfected to prevent the growth of harmful bacteria that could quickly multiply and lead to illness.

Pest Control

Another threat that all manufacturing facilities face is pests. These include insects and rodents who make their way into a facility and can spread bacteria and contaminate surfaces. Facilities that fail to maintain a high level of cleanliness or proper storage practices will be at a higher risk of attracting pests.

Preventative measures should be in place to prevent pests from gaining entry into a facility. This includes things like ensuring entryways are secure and there are no gaps in the foundation. Traps should be present throughout a facility even if a pest problem hasn’t been noticed.

Companies will benefit from hiring a professional exterminator to help them manage pest control processes. This involves monitoring, detection, and prevention in all facilities and buildings.

Food Safety Audits

Food safety audits are an important tool for both companies and governmental regulatory bodies. These audits are a way to check food manufacturing facilities on their compliance with food safety systems and standards.

The food safety auditor has the critical job of inspecting a food manufacturing facility to ensure all aspects of food safety practices are being followed. This includes every step of the process, from food sourcing and handling, to preparation, storage, and transportation.

Audits can be conducted either internally or externally. Internal audits are conducted regularly by the company itself, usually through the use of a permanent positioned employee or manager tasked with overseeing food safety systems.

Internal Audits

Companies can use regular food safety audits as a way to uphold food manufacturing hygiene standards. These audits are aimed at evaluating, monitoring, and documenting activities related to food safety. This also allows companies to identify areas where standards may be lacking or processes can be improved.

Food safety audits can also account for employees' hygiene standards, and ensure that proper training, skills, and knowledge are in place. This can help companies identify employees with knowledge gaps or non-compliance issues.

Internal audits should be performed regularly as a way to ensure compliance and preparedness for external audits.

External Audits

External audits can fall into two categories; second or third-party audits. Second-party audits are conducted by a company that is investigating another company or business. This is often used when food manufacturing companies are considering or evaluating suppliers.

Third-party audits are conducted by independent auditors as a way to test a facility on its food safety systems and hygiene standards. These audits can be performed as a requirement for companies to acquire certification or pass requirements and regulations.

Conclusion

Maintaining food manufacturing hygiene standards is both a requirement and a responsibility for companies operating in the food processing and production industry. Because foodborne illness carries such a high risk to public health, companies who pay close attention to food safety systems can help prevent the spread of illness and disease and can even save lives in the process.

Apart from those responsibilities to consumers, food manufacturing companies that uphold a high standard concerning food hygiene practices stand to benefit at every level. Organizations will have more engaged and efficient employees. They will gain happier, more satisfied, and ultimately loyal customers.

Clean food production helps companies build a positive reputation that will bolster a brand and help keep a business thriving.

The sad part about these statistics is that foodborne illness is almost entirely preventable.

The sad part about these statistics is that foodborne illness is almost entirely preventable.