Connected Worker Insights

Dozuki Announces Record Breaking 2025

Blueprint for Brilliance: Takeaways for Joining the Ranks of the World’s Most Productive Companies

The Future of Manufacturing in 2026: Empowering the Connected Worker

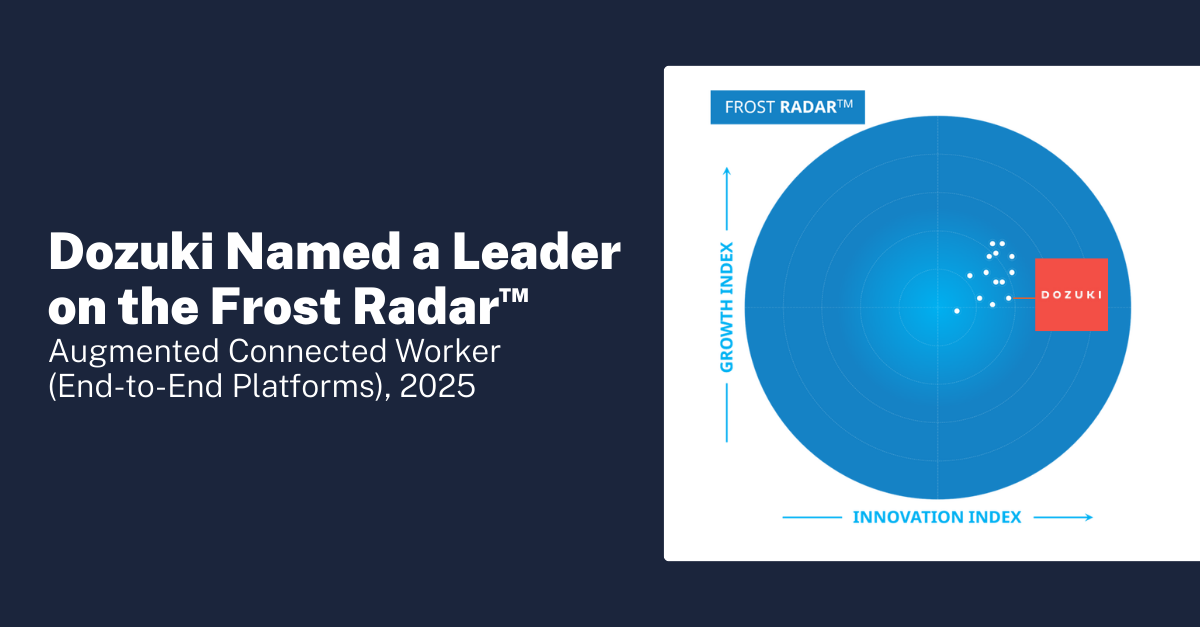

Dozuki Recognized as a Growth and Innovation Leader in Frost & Sullivan 2025 Augmented Connected Worker Platforms Radar Report

Sort by Topic

Rethinking MES in the Era of the Connected Workforce

Most Manufacturing Execution Systems (MES) were built to rigidly enforce processes, not to empower people or evolve how work gets done. MES platforms excel at orchestrating...

Dozuki Announces Record Breaking 2025

Dozuki in 2025: Cementing Global Leadership in the Connected Worker Category Dozuki, the pioneer of the Connected Worker Platform since 2011, today announced its most...

Blueprint for Brilliance: Takeaways for Joining the Ranks of the World’s Most Productive Companies

LNS Research recently released its 2025 Benchmarking the Journey of the World’s Most Productive Companies report, and the findings are a wake-up call for the industrial...

The Future of Manufacturing in 2026: Empowering the Connected Worker

Key Takeaways (The TL;DR) Connected worker initiatives will be central to driving efficiency, safety, and productivity in 2026. Manufacturing technology is advancing...

Subscribe to our Newsletter

Dozuki Recognized as a Growth and Innovation Leader in Frost & Sullivan 2025 Augmented Connected Worker Platforms Radar Report

San Luis Obispo, CA — December 8, 2025 Dozuki, the Connected Worker Platform purpose-built for industrial operations, has been recognized by Frost & Sullivan as a leader in...

The Future of Manufacturing Belongs to the Connected Workforce

How Forward-Thinking Operations Teams Are Reshaping Their Organizations for the Next Decade Walk into any high-performing manufacturing operation today, and you’ll see...

Optimizing Operations with Dozuki Connected Workers

The real barriers to production optimization aren't your people, they're the systems around them. Outdated processes, disconnected information, limited visibility, and the...

How Dozuki Builds a Proactive Safety Culture.

Manufacturing leaders know that safety is non-negotiable. But when processes are undocumented, feedback is unresolved, and training is outdated, even the most basic tasks...

How Mueller Water Reduced Injuries by 20% and Scrap by 60% with Dozuki

Mueller Water is a leading manufacturer of water and gas distribution products used by municipalities, utilities, and contractors. With more than 3,500 employees and a legacy...

How Dozuki Drives a Culture of Improvement

Most manufacturers don’t lack talent, they lack systems. Quality, productivity, and safety issues on the floor often stem from outdated training, undocumented knowledge, and...

How Dozuki Improves Learning & Development

Manufacturers are under pressure. Veteran employees are retiring fast. New hires arrive daily. Turnover remains high. Meanwhile, production tasks are more complex than ever.

How Airstream Reduced Turnover by 83% with Dozuki

By 2017, Airstream was experiencing record-breaking demand. Weekly production targets hit 120 trailers, and the company quickly outgrew its existing footprint. Teams were...

How General Mills Cut Training Time by 62% Using Dozuki

What does it take to streamline training in a fast-paced, high-turnover manufacturing environment? For General Mills, the answer was clear: transform outdated systems into a...

How to Launch a Connected Worker Platform at Your Company

You’re sold on the need for a Connected Worker Platform. But what comes next? If you're here, you're ready. You already understand the risks of relying on tribal knowledge,...

Choosing a Connected Worker Platform? Ask These Questions First.

You’ve either already bought a Connected Worker solution, or you’re about to. But here’s the real question: Did you pick the right one? Frontline transformation isn’t about...

The Ultimate Connected Worker Guide: Why, What, How, Who

Industrial leaders are no strangers to change. New machinery, new regulations, new competitors, these are constants But the last decade has brought a different kind of shift:

How Blue Buffalo Scaled Expert Training with Dozuki

When the team at Blue Buffalo set out to transform how they trained their operators, they weren’t just looking for a software tool, they were looking for a smarter way to...

Dozuki Partners with Isokan Formation in France

Dozuki announces a strategic partnership with Isokan Formation, representative of the TWI Institute, to accelerate its expansion in France and French-speaking countries. San...

How Top Manufacturers Prevent Errors Before They Happen

When a frontline worker makes a mistake, it's rarely due to carelessness. It's more often a failure of training, documentation, or communication. And in regulated industries,...

Why the Connected Worker Is the Future of Manufacturing Success

The manufacturing landscape is shifting at a rapid pace. As digital transformation accelerates, companies that fail to empower their frontline teams risk falling behind. The...

Closing the Skills Gap Before It Costs You

Manufacturers are under pressure. Veteran employees are retiring fast. New hires arrive daily. Meanwhile, production tasks are more complex than ever. Keeping up with...

Why Workforce Agility Is Your Most Strategic Investment

In times of economic uncertainty, slow-moving companies lose. Whether it’s a pandemic, a supply chain breakdown, or a trade policy overhaul, one thing is clear: if your...

The New Blueprint for Manufacturing Skills Development

Manufacturing leaders face a stark truth: without skilled workers, even the most advanced equipment or optimized workflows fall flat. With 27% of the manufacturing workforce

The 4 Roles That Keep AI Knowledge Systems Running

For manufacturers exploring AI-powered knowledge management, the technology alone isn’t the solution. Success depends on people. Specifically, on four key roles that keep...

Introducing CreatorPro AI

The fastest way to digitize operational knowledge, no matter where you’re starting from. In manufacturing, expert knowledge is leaving faster than it’s being captured....

The Role of Industrial AI in Digital Transformation

CreatorPro AI: A Holistic Approach to Digital Transformation Manufacturing organizations face a two-fold challenge when advancing digital transformation efforts: legacy...

The Four Disruptive Forces Reshaping Manufacturing

Manufacturers are at an inflection point. Emerging technologies, shifting customer expectations, and rising workforce pressures are converging—and fast. The pace of change is...

Dozuki Featured on CBS News at World Economic Forum

Dozuki was featured on CBS News at the World Economic Forum in Davos. This segment highlights how digital transformation is no longer optional, but necessary for survival in...

How Dozuki Streamlines Authoring Time

Traditional methods of updating and distributing process documentation can be incredibly time consuming. For one Fortune 100 heavy machinery manufacturer, the manual process...

Dozuki and TWI Institute Partner to Empower Frontline Workers

We’re excited to announce a powerful new partnership between Dozuki and the TWI Institute, combining our strengths to empower frontline workers with effective, hands-on...

How Dozuki Streamlines Knowledge Transfer

Dozuki is changing how companies operate by eliminating unnecessary steps from critical workflows. This article explores how to drive efficiency and highlights a real-world...

Revolutionizing Worker Training with Quizzes in Dozuki

New Dozuki Feature Provides Structured Assessment Tools for Enhanced Comprehension and Skill Development Dozuki, the leading connected worker platform for manufacturers, is...

Dozuki Featured in BBC Article About AI Work Instructions

The recent inclusion of Dozuki in a BBC article highlights a significant shift in how manufacturers are approaching instruction manuals. Traditional methods of thumbing...

How to Build a Custom Library of Digital Process Knowledge

You have probably seen evidence that employee engagement and productivity go hand in hand. But if you're like other manufacturers, you may believe that moving the needle on...

Why You Need a Custom Library of Digital Process Knowledge

No worker operates in a vacuum. Human output potential is a function of our tools, our training, and our mental engagement. Your facility has state of the art tools, a...

Cultivating Versatile Manufacturing Leaders

“If you're an operations manager, a lot of the problems that you solve start to rhyme.”In this episode of the Dozuki podcast, Andrew Dendis from RTX discusses his...

Insights from a Decade of Manufacturing Workforce Trends

In this insightful podcast episode, join Thomas Davis, an experienced training manager, as he unravels the transformative shifts in the manufacturing workforce...

Mastering Value Stream Mapping

"I've never had a leadership team end a mapping activity and say, well, that was a big old waste of time. Never." A seasoned value stream mapping facilitator, Karen Martin,...

Dozuki Names Enterprise Software Veteran Jerry Dolinsky as CEO

Dear Dozuki Community, I am thrilled to reach out to you as the newly appointed CEO of Dozuki. The privilege of leading this exceptional team and community is an honor, and...

3 Mistakes to Avoid When Your Company is in Growth Mode

Our insightful discussion covers the dangers of insignificant improvements, the challenges posed by an overload of initiatives, and the drawbacks of rigid processes. Learn...

How 3 Leaders Tackled Key Workforce Challenges

A recent survey by the National Association of Manufacturers underscores a pressing concern for manufacturing executives. Nearly 75% identify attracting and retaining a...

Decoding the Manufacturing Labor Market

"It's a very tight labor market. For every 1.5 job openings, there's only one unemployed worker.”Join Chad Moutray and Anjana Radhakrishnan from The Manufacturing Institute...

Building A Culture Of Knowledge Capture

In digital manufacturing transformation, tablets are merely the artifacts. When you equip your operators and technicians with the right technology, not only do they document...

A Paradigm Shift in Quality

"Do not create defects, do not pass defects and do not accept defects." This philosophy is critical for manufacturing digital transformation.In this episode, we sit down...

A Playbook for Tech Success in Regulated Industries

"When I wake up in the morning to empower an operator and an engineer, and they're using software from four versions ago, then I'm failing them."A former director and manager...

Maximizing ROI in Year End Budget Talks

The year-end budgeting season is a crucial time for manufacturing organizations to make strategic decisions. Not only about traditional tangible assets like equipment,...

5S and Beyond: Elevate Your Lean Journey

In this episode, we learn the importance of standards in your 5S program. From visual controls to supply procurement and accountability, standards play a pivotal role in...

Manufacturing 5.0 Balancing Human Expertise in the Digital Era

If you’re starting with technology, you’re starting wrong. Manufacturers that start with people, and then follow with technology, stay competitive in the changing...

From Flame To Flourish: End Firefighting

"At a traditional manufacturing organization, your goal is to solve the problem as quickly as you can and get back to equilibrium. But at a lean organization, your goal is to...

How Connected Worker Solutions Reduce Onboarding Time

New employee onboarding is a crucial process that directly impacts a company's productivity and bottom line. On average, the cost of onboarding a new hire amounts to ...

Equipping Your Frontline for a Digital Future

"Workers are more accepting when tools are not a solution that means more work for them." Wise words from Bill Tomlinson, a veteran Training & Development leader at...

From DIY Solutions To Data Driven Breakthroughs

"Quality assurance is about transforming digital acquisition into information that you can leverage."This might be our most tactical and encouraging episode yet! Mark Gobessi

Connected Workforce | What Is It & How Does It Benefit Companies?

One of the best ways businesses can get ahead and remain competitive is to embrace the available tools. And right now, that means implementing a connected workforce. Table...

Skillsets + Mindsets = Frontline Employee Engagement

"I need to know I'm spending my time solving problems, not finding them."Wise words from Jonathan Keiper at MPP Innovation, who talks about the significance of engaging the...

How Connected Worker Solutions Combat Worker Shortages

The manufacturing sector has always played a crucial role in the economy. But our industry has been grappling with a notable shortage of labor in recent years. This...

I Got 99 Problems, But Skills Ain’t One

How many of your frontline manufacturing workers are engaged, productive, and feel a sense of ownership in their process? Manufacturing Digital recently reported that...

Navigating Industry 4.0: Insights from a Manufacturing Innovator

"We literally have to create the talent if we can't find it." These inspiring words (and more!) come from our Season 2 kickoff conversation with LaRuthie Mason, who works at...

Knowledge vs. Skills: Why Manufacturers Must Train For Both

Two terms manufacturing leaders use a lot are knowledge and skills. You’ve probably read material and even participated in training programs around topics like tribal...

Inside the Box: Unwrapping Trends and Tactics in CPG Manufacturing

The formula for CPG manufacturing has some new variables: Consumers reshaped consumption habits in the pandemic.Employees are hitting the factory floor with no skills or...

Dozuki's Secrets to Drastically Cut Scrap Waste

Snuffing out the waste in manufacturing is difficult, but not impossible.Facilities who are successful in their waste reduction efforts will gain benefits in terms of cost...

Creating The Frontline Of The Future, Part 10

Does your facility have a suggestion box? Or is there a more formal framework for collecting and implementing process feedback from your frontline workers? Most...

How a Small Machine Shop Became a Top 20 Supplier to NASA

“Be careful with that silicon wafer. It's worth more than your house.” Rodney Babcock, President of Next Intent, learned this lesson as the quality assurance manager...

What The Doc Ordered: Better Performance in Medical Manufacturing

The landscape of medical manufacturing has gotten more complex. Pandemic related shutdowns created global supply chain disruptions A batch of macroeconomic and regulatory...

Creating The Frontline Of The Future, Part 9

Workforce Development You’ve probably heard the adage, the tool is as only as good or bad as the user. We believe this principle has broad applications in digital...

Streamlining Production: How Lean Manufacturing Can Revolutionize Your Business

Manufacturing is a delicate process. So many moving parts must come together just right if the aim is to produce goods of the highest quality in the most cost-effective way...

How to Hold a Rattlesnake Hunt at Your Factory

“The experts are the people that do it every.” Mark “Southern Sensei” Preston has been driving change in manufacturing and front office environments for over thirty years...

Creating The Frontline Of The Future, Part 8

Alignment Fosters ScalabilityIn the early stages of digital transformation, only a few stakeholders are involved Manufacturing companies typically begin their journey by...

Dozuki & TWI Institute Announce Strategic Partnership To Reimagine How Manufacturers Train The Frontline

Dozuki and the TWI Institute are thrilled to announce an exclusive strategic partnership that combines TWI’s industry-leading training methodology and best practices with...

How Governments Play a Role in Supporting Manufacturing

"Train the workforce first, and then introduce new technology. Otherwise that tech will be sitting in a corner with a tarp over it." Paul Lavoie first fell in love with...

Creating The Frontline Of The Future, Part 7

Technology Enables Resilience Do you know what the first manufacturing technology was? Let’s go back to prehistoric times, over two million years ago. The Stone Age...

Maximizing Efficiency: A Guide to Total Productive Maintenance

Maintenance is an essential requirement for any manufacturing company. Whenever machinery and equipment enter an equation, there will be a likelihood of that machinery...

How to Build a Thriving Machine Shop

“We make the components that make the magic happen. Everything else is just a sculpture.”That’s the economic value of precision manufacturing. All those machined parts...

Driving Fear Off The Factory Floor

Did you know there are five fears that all human beings share? Below is the official list, according to the widely cited psychological research outlined in Karl Albrecht’s...

A Deeper Look Into Quality Assurance vs. Quality Control in Manufacturing

Manufacturing is taking raw materials and turning them into a product people need. Our industry makes the world go around. But competition, which is in part responsible for...

Manufacturing The Heavy Way: Unlocking Productivity Gains

Disruption is the new status quo in heavy equipment.Supply chain challenges continue to impact production.Covid accelerated labor trends that impact every part of the...

A Food Manufacturers Recipe for Quality

The status quo for food and beverage manufacturing has some new ingredients.Consider several of the social, economic, and cultural trends impacting the industry: ...

Frontline Of The Future, Part 6

How To Staff Your Front Line Without ExcelOne of our customers, a plant manager at a chemical manufacturing company, made this observation:“Getting the time to train every...

How Auto Manufacturers Can Avoid Production Potholes

Automotive manufacturing has been a windy road. Here are a few of the social, economic and cultural trends currently impacting automotive manufacturing. But automotive...

How To Go From Worst To First

"We're paying them for their hands, but they're freely willing & able to give of their hearts, if you engage them and help them with this vision." Erik Richardson shared...

Identifying Defects: How Root Cause Analysis Will Save Manufacturing

Manufacturing companies work hard to build a lean culture. The never-ending march toward the ideal of perfection through the motto of continuous improvement requires constant...

Frontline Of The Future, Part 5

In any type of manufacturing, lubrication is essential.It reduces wear, minimizes friction, dampens noise, dissipates heat, and absorbs shock on machine components. Human...

Operational Resilience Explained

America was built on manufacturing.And manufacturing was built on resilience. Our country has proven to be a place where workers who are skilled with their hands (and have...

What Manufacturing Leaders Need to Know About Workforce Empowerment

Empowered workers require enlightened leaders. Organizations can either act as an incentive (or an obstruction!) to the expression of a frontline worker's sense of ownership.

How to Create a Daily Management System

Do your frontline employees know if they’re winning or losing each day?The answer to that question is simple, but not easy.Michael Muilenburg spent 35+ years at 3M building a...

Frontline Of The Future, Part 4

According to recent numbers from the Bureau of Labor, there are 12,559,000 manufacturing employees in the country. That’s eight percent of our nation’s employment. And yet,...

Why Do Value Stream Mapping? | Benefits & Examples

A successful business incorporates two critical factors, customers, and cost. The goal of any business is to provide the most outstanding value for the customer at the lowest

Manufacturing Doesn’t Have A Hiring Problem, It Has A Retention Problem

Consider two pieces of recent industry data: 75% of the workforce will be millennials by 2025. (Forbes) Thousands of experienced workers are retiring daily. The Silver Tsunami

11 Essential Workplace Safety Tips for a Secure & Healthy Environment

Workplace safety is a topic that businesses simply cannot overlook. For one thing, employers have an obligation to their employees to provide a safe work environment and to...

Firefighting In Manufacturing

Why It Happens, What It Costs, and How To Stop It Firefighting is a burning issue in manufacturing. Not only are facilities dealing with safety measures like flammable...

How to Deliver People Centric Manufacturing Training

“The supervisor is the customer of the training.” When Vitalii Potapenko of Solar Plastics first shared these words with us, we knew their company was doing something special...

Frontline Of The Future, Part 3

Accessibility Creates Profitability Manufacturers that don’t provide broad access to essential knowledge are at a significant deficit. This form of content debt comes at a...

The Cardinal Rule of Process Documentation: Read the Comments

We’re told the cardinal rule of the internet is, “Never read the comments.” This catchphrase is used to warn users of the toxic parts of the internet. One minute you’re...

Frontline of the Future, Part 2

Digitizing Your Processes Do you have a process for process? Or are disconnected paper systems preventing valuable efficiency gains? Most manufacturing companies would say...

The Cost of Losing Frontline Employees

Here's How To Avoid Paying It Employee retention is as important (if not more important) than hiring workers. At any given manufacturing organization, a single frontline...

A New Model For Manufacturing Hiring

Constraint, Currency & Clarity What invention had the most profound impact on manufacturing hiring? Not the steam engine. Not the assembly line. Not lean practices. Not...

Frontline of the Future: Part 1

Historical Forces Impacting Manufacturing At Dozuki, we have our finger on the pulse of manufacturing trends. We believe it’s part of our mission to formulate clear...

A Comprehensive Guide to Predictive Maintenance in Manufacturing | 2023

Effective maintenance requires a well-rounded approach. Manufacturing companies use planned, reactive, and proactive systems to prevent breakdowns and address problems as...

How to Tackle Hiring By Recruiting Student Athletes To Man The Line

Factories are fighting to fill open roles. And a lack of standardization creates a bottleneck that makes it hard for frontline employees to hit the ground running on day one.

How To Accelerate Frontline Learning With TWI

Frontline supervisors are not educated as teachers or coaches. The good news is, they can learn that skill. Most training programs focus on training operators, and we have...

4 Ways Digital Tools Improve Quality

Twenty years ago, digital tools were “a thing.” Now they flow through all things. To some degree, every manufacturer is now a digital company. And with the right modern...

Overcoming Manufacturing Lead Time | What Is Lead Time & How To Reduce It?

Manufacturing companies rely on their ability to get products to customers quickly and efficiently. If it’s one thing customers are not, it’s understanding when it comes to...

The Most Common Manufacturing KPIs and Metrics to Track & Why | 2023

Manufacturing is a highly competitive industry, and the road to success has been uphill for many businesses over the last several years. Table of Contents Criteria for...

The Myth of Augmented Reality in Manufacturing

Do you remember Glass? Not the epic 2019 finale to the superhero trilogy with evil genius Samuel Jackson. I’m referring to Google’s failed launch of their smart glasses. Back...

The Cost of Bad Work Instructions

Bad work instructions are the norm. Documentation is often created to check a box for audit or compliance purposes. But once completed, those work instructions get trapped...

Impact of AI in Manufacturing: Benefits, Challenges & Use Cases

Artificial Intelligence has become a hot topic in society today. What once was a term relegated to science fiction novels is now commonplace among people from all walks of...

Quality Assurance in Manufacturing: An In-Depth Guide to Achieve Customer Confidence

It’s time to talk about quality. In this industry, quality is everything, and competition between manufacturers is fierce. Table of Content 1. Key Principles of Quality...

Push vs. Pull System in Manufacturing: A Complete Overview for Optimizing Production

fthoughtsManufacturing companies must carefully balance expenditure and revenue to remain profitable. It might sound simple when put that way, but every manufacturer knows...

Best Methods to Reduce Human Error in Manufacturing

In manufacturing, many factors need to be balanced and aligned for companies to be successful. And one of those factors includes the combination of humans and machines...

Best Practices to Maximize Production Capacity in Manufacturing | 2023

According to the numbers, manufacturing makes up around 12% of the U.S. GDP and provides jobs for 12.984 million Americans, or about 9.6% of all U.S. workers. In other words,...

Benefits of Procedures & Work Instructions in Manufacturing

Ah, the lingo of business. If there’s one thing that the world of business and industry loves, it’s terminology. Every industry has developed its own language, with specific...

What Makes a Good Digital Work Instruction Software?

When Bob Dylan sang the lyrics, “the times they are a-changin’,” he probably never envisioned what the world would look like just six short decades later. The rise of digital...

Continuous Manufacturing: Streamlining Production for A Competitive Edge

Continuous manufacturing (CM) is a production method that has gained a lot of attention in different industries due to its ability to streamline production, enhance profits...

Best Practices of Food Manufacturing Hygiene Standards

Food manufacturing companies have a responsibility to their customers to maintain high-quality control measures and hygiene standards. These practices are necessary to ensure...

5 Ways to Fix the Skills Gap on the Factory Floor

Properly addressing the skills gap takes time. But before you start forming an internal task force or scheduling strategy meetings, consider what impact you can have on the...

5 Ways To Improve Quality Control in Manufacturing

In manufacturing, quality is everything. Businesses need to focus on creating products that are high quality enough to meet or exceed the customer's needs if they want to be...

How To Hire the Best Employees for Manufacturing

Employees are the backbone of any company. Nowhere is this more true than the manufacturing industry. Statistics show there are 15.7 million employees in the manufacturing...

Understanding Corrective Action vs. Preventative Action in Manufacturing

One of the most important aspects of a successful manufacturing organization is the ability to solve complex problems as they arise. In keeping with the continuous...

Solving Modern Workforce Challenges in Food & Beverage Manufacturing

In the midst of unprecedented market demands and supply chain issues, the most innovative food & beverage manufacturers are finding new, creative ways to support an efficient...

How To Reduce Defects in Manufacturing in 2022

Product defects are a pain at any manufacturing company. When all the time, energy, and money that is spent to produce a product is wasted due to defects in the final...

Best Practices On How To Retain Factory Workers

Manufacturing companies rely on workers to be the frontline of production. And while companies across all sectors struggle to recover from a labor crisis perpetuated in part...

11 Common Manufacturing Challenges & Solutions | 2023

When it comes to industry, manufacturing might be one of the most challenging. Because of the high cost of doing business, the need for skilled workers, and an...

Effective Ways To Reduce Employee Training Costs In Manufacturing

If you have a business that includes the use of employees, one of the first and most important tasks you must fund is training. This is true of all industries, but companies...

How to Find Support Investing in Manufacturing Technology

Manufacturing companies are all interested in improving technology on the factory floor but often lack the resources or know-how to get started. This week we speak with Ron...

How to Effectively Train New Employees at Factories

In the manufacturing industry, effectively training new and current employees is the backbone of production. However, simply training new employees on the basics is not...

6 Common Manufacturing Facility Hazards & Effective Solutions

Manufacturing facilities serve an important function in a country’s economy, as they create jobs, increase wealth through added value and taxes, promote trade, and support...

How to Manage Mobile Devices on the Factory Floor

Tablets and smartphones can transform your industrial operations. This week we are joined by Jacob Rattray, Operational Technology Specialist from 3M. Jacob specializes in...

How To Increase Productivity in Manufacturing

There are several ways to define productivity depending on the context. In terms of manufacturing, productivity relates to the speed at which quality work is performed....

Gemba Walk Template for Digital Transformation

Gemba Walks are an essential tool to understand the challenges of your manufacturing frontline. Each manufacturing facility is unique. The best way to solve your unique...

7 Best Practices in Manufacturing Training for Employees

Training employees is a surefire way to improve productivity and efficiency within manufacturing. As the company grows and expands, its employees must also grow with it,...

How to Get Started with Automation in Manufacturing

Automation can benefit all industrial operations, from large to small manufacturers, by streamlining repetitive or dangerous tasks while adding valuable skills to your...

Using Digital Tools as a Recruitment Tool in Manufacturing

Manufacturers are being squeezed in both directions these days. Demand for products is outpacing their ability to secure raw materials for production, and they don’t have...

How the Best Plant Managers Solve Production Challenges

As a manufacturing plant manager, meeting production targets, reducing downtime, and filling empty roles are all ongoing goals. The best plant managers know that these goals...

What is Frontline Digital Transformation?

Manufacturing leaders agree that adopting digital technology is essential to future success. Despite this mindset, 84% of digital transformations fail to improve performance...

6 Shocking Stats for Manufacturing Leaders

After years of research, our show producer, Corey Brown, shares some fascinating statistics that will shock many leaders in the manufacturing industry. In this special...

How to Improve Performance with Preventative Maintenance

Equipment failure is a known evil in the manufacturing world. But unplanned downtime carries a significant cost and hurts overall performance. This week Brian sits down with...

A Complete Guide to Visual Management in Manufacturing | 2023

Visual Management is a concept that can apply to everyday life - and life on the plant floor as well. As we go about our day, we encounter visual management cues in different...

Recent Mobile App Updates

Dozuki is a frontline work training platform for industrial companies who depend on operators to meet production standards. Our mobile app is used by frontline operators to ...

How to Scale Technology Across Manufacturing Operations with 3M

Most manufacturing companies don't have people dedicated to evaluating and deploying modern tools. At best, IT or HR takes responsibility for new technology and doesn't have...

How to Communicate Change with the Frontline Workforce

People are the most overlooked aspect of digital transformation — 97% of companies’ digital transformations fail when they don't include line managers and operators. ...

Career Progression in the Manufacturing Industry

Today's manufacturing facilities are clean and modern workplaces that offer a variety of unique and exciting career opportunities. Join our conversation with Joe Renaud from...

Top Challenges Impacting the Frontline Workforce

Even with advancements in technology and automation, the frontline workforce remains essential to modern manufacturing operations. In fact, 72% of factory work is still...

Using Standards to Empower the Frontline Workforce

Chad Nelson is a Lean Six-Sigma Operations Manager at 3M and has a wealth of knowledge about standardized work and engaging frontline workers with improvement efforts. Join...

How to Manage Change on the Plant Floor

Change management is a crucial part of any digital transformation or improvement efforts on the plant floor. But how do you deal with stubborn employees or older workers that...

Dozuki Secures Strategic Investment from Marlin Equity Partners

Demand-side challenges accelerated by the COVID-19 pandemic are driving adoption of frontline-focused training platforms in manufacturing. --We are pleased to announce a...

Digital Technology Trends in Manufacturing

In the past, manufacturing technology was focused on improving equipment and tools. Now, the industry is shifting its priorities towards workforce enablement. How will the...

Insights from the Field: Training is More Than Onboarding

I was recently on a trip to visit a manufacturing facility for one of our clients. My connecting flight didn’t arrive on time, which delayed my arrival and put me on a tight...

ISO 9001 Certification is Easier Than You Think

Is audit anxiety holding your company back from ISO 9001 compliance? While it may seem like a daunting task, many businesses are closer to certification (and...

Adapting Training to Meet the Needs of the Modern Manufacturer

Manufacturers are faced with a much different workforce than they've traditionally dealt with. Previous generations had more foundational knowledge, incoming generations need...

Mastering Total Quality Management in Manufacturing (TQM) | Strategies and Insights

If there’s one consistent thread that unites every manufacturer worldwide, it’s quality. The need to produce a quality product that meets or exceeds the needs and...

How to Attract and Retain a Qualified Manufacturing Workforce

Welcome to the first episode of The Voices of Manufacturing! Join us in conversation with Jim Vinoski, a Forbes Author who specializes in all things manufacturing. As...

5 Ways to Get Wifi on the Factory Floor

Here’s the reality, many industrial environments lack wireless internet. It’s not for a lack of trying. However, there are real, pragmatic reasons that some companies can’t...

The Most Common 8 Wastes of Lean Manufacturing & How to Manage Resources

Manufacturing is all about making the highest quality products at the lowest cost. Reaching that goal means searching for and eliminating causes of wasted time, wasted...

Why HR Shouldn't Manage Your Technical Skills Training

Amid the Silver Tsunami, HR departments are hustling to onboard and fill personnel gaps, but they can’t predict the evolving demands of your operations. Manufacturing...

Where is Your Implicit Knowledge Hiding?

Implicit (tacit) knowledge is difficult to communicate and often remains isolated in the heads of employees. However, this accumulation of operational skills and insights has...

Top Podcasts for Manufacturing Professionals

The podcast space is growing rapidly and the shows for manufacturing and industrial professionals are no exception. Podcasts in this genre can range from broad industry...

Why Sharepoint Fails at Knowledge Management

Many industrial businesses rely on generic document management tools, like Microsoft Sharepoint, to store and share files. As a document management strategy, this makes...

Document Management Vs. Knowledge Management

Understanding the distinction between document management and knowledge management is vital to operational excellence. While the terms can sometimes be used interchangeably,...

The Missing Piece of Your Digital Transformation Strategy

Unprecedented. There probably isn’t a better word to describe 2020 as a whole. 2020 saw accelerated change across almost all industries and aspects of our lives. In...

How Smart Factories are Impacting Productivity

Deloitte research suggests that "smart factory" initiatives have yielded an average of 10-12% increase in labor productivity gains. Despite this success, a majority of...

Preparing Your Workforce for the Silver Tsunami

Manufacturing businesses need a succession plan. Not for people, but for knowledge. The industry is facing a wave of retirement unlike any other. Often referred to as the...

Why Your Work Instructions Need Quality Checklists

Quality checklists or inspections are a routine part of production. While they are a crucial part of quality management and control, checklists only catch errors, rather than...

How to Get ISO 9001 Certified with Dozuki

As the most commonly used standard for quality management systems (QMS), the ISO 9001:2015 standard implements a preventative, risk-based approach that puts documentation at...

How to Write Better Lockout/Tagout Procedures

Lockout/Tagout (LOTO) procedures are some of the most common in industrial and manufacturing environments. Despite this, failure to adequately train employees on LOTO...

How Digital Tools Enable Rapid Communication for Manufacturing

The ongoing global COVID-19 pandemic has forced companies of all types to rapidly update policies and procedures governing how they share information in response to a world...

How to Capture Expert Knowledge Before it's Lost

It’s no secret. Manufacturers are coping with a massive wave of retirements. With over a quarter of the workforce over the age of 55, many workers are leaving their jobs with...

4 Indirect Ways to Improve Safety on the Plant Floor

Safety managers have a multitude of safety strategies to protect the health and safety of their workforce. From PPE guidelines, LOTO programs, fire exit signage, the list is...

Top Challenges for Food & Beverage Manufacturers

Food and beverage companies are among the most resilient and adaptive businesses in the world. With inherent health and safety risks, volatility of perishables, and strict...

How to Get More Out of Your Work Instructions

When leveraged properly, standardized work instructions can transform operational efficiency, quality management, employee performance, and more. All industrial businesses...

How 3M Continues to Innovate During COVID

Amid the COVID-19 pandemic, 3M has been integral in maintaining domestic and international supplies of essential PPE. These production and supply chain challenges required...

OSHA's Recommended Strategies for Improving Safety Programs

Workforce safety is non-negotiable for any industrial business. When mistakes can cause serious harm or bring operations to a halt, companies can’t afford to take safety...

How to Use Dozuki for Work Instructions

Dozuki is the leading digital work instruction tool for industrial businesses all over the world. Our platform enables better employee performance by improving how you...

How To Choose Industrial Tablets for Manufacturing

Investing in technology is a key part of any company's digital transformation strategy. It's impossible to hit digital goals without the right hardware — and software — to...

6 Strategies to Maximize Worker Safety

In industrial companies, workplace safety is the #1 driver behind many key decisions. Not only is safety essential for protecting workers, it’s also essential for consistent...

Free COVID-19 Workplace Signage

Whether your team is on site, or working remotely, we know that your time is taxed by demanding workloads and new safety procedures. In an effort to take one task off your...

How To Cross-Train Your Workforce

Cross-training is an essential component of any successful manufacturing company. The flexibility it creates enables your operations to continue regardless of what operators...

Is the U.S. Headed for a Manufacturing Boom?

While many industrial businesses are impacted by the COVID-19 pandemic, good news for U.S. manufacturers may be on the horizon. In the recent April industry report by...

What is Tribal Knowledge?

Many industrial businesses have heard of the dangers of relying on tribal knowledge. But what exactly does tribal knowledge mean? How does tribal knowledge impact my...

Practical COVID-19 Tips for Manufacturing

We are hearing a lot of great advice from our audience and customers about how to keep manufacturing and industrial operations running smoothly in the midst of a global...

Breaking Down the Skills Gap: Tribal Knowledge

As the skills gap widens and more employees retire, decades of experience and company investment is predicted to walk out the door. With nearly ten thousand people turning...

Breaking Down the Skills Gap: Training

Manufacturing Institute estimated that 2.4 million job openings in manufacturing—accounting for half of all open positions—will go unfilled between 2018 and 2028 as a direct...

Breaking Down the Skills Gap: Recruiting & Retirement

For those in the manufacturing and industrial sector, what’s commonly known as the skills gap is a well-documented issue. As a growing number of Americans retire, they take...

How to Reduce Changeover Time with Standard Work Instructions

Many manufacturers see reducing changeover time as a golden opportunity to improve operational efficiency and reduce waste. For good reason, a simple reduction in changeover...

Dozuki Collaborates with 3M to Connect Factory Workers and Digital Transformation Strategies

Today we are happy to announce our collaboration with 3M, through an investment by 3M Ventures, to bring our standard work and work instruction training software to...

What's Wrong with Standard Work?

66% of companies fail in their attempts at Standard Work. This begs the question - what’s wrong with Standard Work? How can a seemingly simple methodology be so challenging...

Lean Manufacturing Lessons From Wikipedia

When Jimmy Wales, founder of Wikipedia, was interviewed on NPR’s “How I Built This,” he revealed a valuable insight — sharing and improving knowledge is hard work. The...

Free Standard Operating Procedure & Work Instruction Templates

Standard operating procedure (SOP) and work instruction templates help standardize processes and present information consistently. We’ve seen thousands of examples of these...

Insights from the Field: Can Tribal Knowledge Actually Work?

Recently, I had a chance to visit one of our larger manufacturing clients. Of the many insights gained on that trip, one stood above the rest — tribal knowledge used to...

Manage Workforce Training with Dozuki Courses

At Dozuki, we’ve made it our mission to make Standard Work an industry standard. We envision documented standards and worker knowledge continuously improving alongside one...

How On-the-Job Training is Hurting Manufacturing

While on-the-job training is practical for certain applications, manufacturers rely on it too heavily as a method for on-boarding and training employees. Companies looking...

Software Support and Your Digital Transformation Strategy

After thousands of discussions with manufacturing companies, it’s clear to me that the industry is suffering. Due to outdated notions of the software industry, manufacturers...

How to Reduce Tribal Knowledge and Downtime with Dozuki Answers

The conveyor belt on line one stopped running and production came to a halt. It was the second time in a week that this happened. The maintenance team and engineers spend the...

What is Standard Work?

Lean operations and manufacturers have used Standard Work for decades, yet many companies lack clarity when it comes to this fundamental lean methodology. How is Standard...

A Lesson in Lean Manufacturing From the North Pole

If Santa Claus ran a toy company, he’d have the best lean manufacturing operations in the industry. A lean analysis shows that he delivers custom tailored products to every...

Lean Thinking vs. Cost Cutting with James Womack

When properly applied, lean manufacturing principles cut costs by reducing waste and focusing on value. But many companies make the vital mistake of confusing cost cutting...

How to Create a Culture of Knowledge Sharing and Continuous Improvement

If a proper culture of knowledge sharing is in place, the skills that experienced employees possess can be leveraged to improve your business and culture. Every manager knows...

4 Signs Your Work Instructions Need an Upgrade

Knowing when to make the transition to a better documentation tool is a tough question to answer. The short answer is that there is no short answer. In Industry 4.0, a...

What Chipotle Taught Us About Training Standards

Chipotle, the Mexican food chain, has been in the spotlight recently for a variety of reasons. Unfortunately, not all coverage has been “good press.” A string of food safety...

Visit us at AME International 2018

Dozuki will be exhibiting at the AME San Diego International Conference. The event takes place from October 29 - November 1 at the Manchester Grand Hyatt in San Diego, CA. ...

Electronic Work Instructions in Industry 4.0

How do electronic work instructions factor into Industry 4.0 and your digital transformation strategy? With advancements in technology, it’s time to reevaluate how these...

7 Stats in Celebration of Manufacturing Day

In the past, we put together a dream team of manufacturing icons and their contributions. In celebration of Manufacturing Day 2018, we’d like to share key statistics to...

Catch us at the 2018 Assembly Show

Dozuki is back in Chicago for the 2018 Assembly Show. The event takes place from October 23 - 25 at the Donald Stephens Convention Center in Rosemont, IL. This event is...

How to Establish a Lean Culture in 4 Steps

An effective lean culture aims to reduce waste and inefficiency while improving the value delivered to customers. The lean organization is a model that’s been historically...

Book Club: "Leading Change"

"Leading Change" by John Kotter offers an eight-step process for managing change and has become the foundation for organizations around the world. By outlining the process...

Kaizen and Standardization with Dr. Robert Maurer

We spoke with Dr. Robert Maurer, author of “Spirit of Kaizen,” a leading expert in the field of psychology and organizational change, about Kaizen and the role of...

Visit us at IMTS 2018

Dozuki will be exhibiting at the 2018 International Manufacturing & Technology Show (IMTS). The event takes place from September 10 - 15 at the McCormick Place in Chicago, IL.

Lean, Six Sigma, and Quality Management Systems

Six Sigma, Lean, and Quality Management are distinct approaches to reducing waste, defects, and providing value to the customer. With so many approaches to process...

11 Benefits of Standard Work

Taiichi Ohno, a founder of the Toyota Production System (TPS), had this to say about Standard Work, “without standards, there can be no Kaizen.” As the foundation for all...

Understanding Value Streams with Karen Martin

Employee on-boarding is often overlooked in the business world. We spoke with Karen Martin, author of "Value Stream Mapping" about why all supportive processes are equally...

10 Quality Quotes by W. Edwards Deming

Implementing and sustaining quality in your organization is no small feat. However, as the U.S. discovered when Japanese companies like Toyota used Deming's lessons to...

Book Club: “The Joy of Lean”

The Dozuki book club is your go-to place for industry books and resources. Our team curates knowledge from industry experts, letting you identify key takeaways and start...

The Manufacturing Skills Gap is an Opportunity

There is a pending manufacturing skills gap impacting the United States workforce. Millions of positions are expected to go unfilled in the coming years, with reports...

Inside the Mind of an ISO Auditor

Getting inside the mind of an ISO 9001 auditor is crucial to a successful ISO audit. Think of it like a gift — even the best of presents can be unappealing when wrapped in...

Embracing Waste in a Lean Culture

These days, waste gets a bad rap. ‘Eliminating waste’ is such a common phrase among lean and six sigma practitioners, the two words are practically inseparable. The problem...

What to Look for in QMS Software

Traditional quality management system (QMS) software does exactly what it’s supposed to do. Like file cabinets for the digital world, they organize and control your company...

Book Club: “The Machine That Changed the World”

The Dozuki book club is your go-to place for industry books and resources. Our team curates knowledge from industry experts, letting you identify key takeaways and start...

In Conversation with John Allwood

Standard Work is a concept that’s widely accepted among lean practitioners, yet doesn’t have a large body of text detailing its application. When used properly, Standard...

Manufacturing & Technology Show

Dozuki will be exhibiting at the 2018 Manufacturing & Technology Show, presented by IndustryWeek. The event takes place from May 8 - 10 at the Raleigh Convention Center in...

Catch Us at the Food Safety Summit

The Dozuki team will be at the 20th annual Food Safety Summit, May 7 - 10 at the Donald Stephens Convention in Rosemont, IL. You'll find us alongside other companies leading...

World Conference on Quality and Improvement

We'll be at the ASQ World Conference on Quality and Improvement, April 29 - May 2 at the Washington State Convention Center in Seattle. Along with other innovators and...

Meet Us at Hannover Messe 2018

Dozuki is proud to be an exhibitor at this year's Hannover Messe, the world’s leading trade show for Industrial technology. You can find us in the Digital Factory hall....

Book Club: "Value Stream Mapping" (part 2)

The Dozuki book club is your go-to place for industry books and resources. Our team curates knowledge from industry experts, letting you identify key takeaways and start...

Vienna Sausage: A Story of Standards and Tribal Knowledge

Imagine that you lost the ability to make your key product. What if your core revenue driver was suddenly different... And you didn't know why. We recently came across a ...

How to Perform a Time Observation

Without Standard Work, documented processes are often not used, or so out of date, that following them could become problematic. Standard Work is the foundation for any...

Key Differences Between ISO 9001:2015 and 2008

ISO 9001 is the world’s most commonly used standard for quality management systems (QMS). About every 7 years, ISO updates their standard to reflect the changes in global...

Top 10 Shigeo Shingo Quotes on Lean Manufacturing

Shigeo Singo: The Ambassador of Lean Shigeo Shingo was an industry leader of Lean manufacturing principles and philosophies. Originally brought on by Toyota to update their...

Navigating Processes: Standard Work vs. Work Instructions

The manufacturing industry is a professional arena with an overwhelming variety of industry terms and acronyms. We’ve tried to make a list of the most common Lean terms...

Book Club: "Value Stream Mapping" (Part 1)

The Dozuki book club is your go-to place for industry books and resources. Our team curates knowledge from industry experts, letting you identify key takeaways and start...

Why Standard Work is a Contradiction

We recently wrote a popular article about a major mistake at a nuclear waste facility. In short, we cited poor standard revision processes as the root cause of the mistake,...

Implementing Continuous Improvement with Dozuki

Is your company interested in reaping the benefits of continuous improvement (transparency, efficiency, cost reductions, etc.) but aren't sure where to begin? Dozuki has you...

What Caused the False Missile Alert in Hawaii

Apparently, it was a simple mistake that caused the false missile alert to be sent to phones across the state of Hawaii. And while citizens were still recovering from the...

Continuous Improvement Culture: How Software Can & Can't Help

Fostering a culture of continuous improvement is a complex challenge that varies across industries. In the digital age, software solutions are starting to have a real impact...

Hidden Waste: The Unseen Inefficiency in Shop Travelers

Travelers and build books are intimately related, however, with traditional methods they often function independently. This gap between the travelers and build books creates...

Top 10 Lean Manufacturing Quotes from Henry Ford

Henry Ford was a very quotable man. His timeless insights range from practical business tips to clairvoyant-esque predictions about the dairy industry. While some of his...

5 Reasons Continuous Improvement Teams Fail

In identifying what makes a continuous improvement team successful, it’s most helpful to look at where they fail. Anyone can retroactively attribute key factors to success,...

Book Club: "The Spirit of Kaizen"

About the Dozuki Book Club: Your go-to place for industry books and resources. Our team works hard to curate knowledge from industry experts, letting you quickly identify key...

The Ultimate Lean Glossary

The world of Lean Manufacturing is full of acronyms and industry buzzwords. No glossary could encompass the full breadth of terminology, but it’s always helpful to have a...

Top 10 Taiichi Ohno Quotes

Wise quotes can inspire. Insightful sayings have the power to spark change and foster a culture of creativity and quality. Whether it’s on a sticky note clinging desperately...

Got Standards? The Million Dollar Grammar Mistake

Maine based Oakhurst Dairy was recently sued by a handful of truck drivers seeking more than four years worth of overtime pay—but the suit wasn’t about milk distribution at...

Skip the Busy Work and Focus on Improving

Whether you’re implementing new software or a new machine on the factory floor, continuous improvement projects take time to get set up before they, well…improve things. ...

Deadly Instructions: Using Visuals to Train Safely

In 2016 OSHA reported 2.8 million workplace injuries, with 440,000 of them occurring in the manufacturing industry alone. For manufacturers, that means for every 100 workers,...

An Idiom a Day Keeps Good Work Instructions at Bay

Many of us know Amelia Bedelia from our childhood (or parenthood) as the goofy maid who is constantly misunderstanding directions. For those who aren’t familiar, Amelia is a...

5 Technical Writing Mistakes to Avoid

Here at Dozuki, we see a lot of technical documents. In all of this written work, we inevitably come across some mistakes. But hey, pobody’s nerfect. That said, when you see...

How Dover Artificial Lift Achieved ISO Certification

As part of our mission to bring manufacturing excellence and standards to our audience, we are proud to announce our educational webinar highlighting the journey to ISO...

Millennials, Vinyls, and Documentation

Vinyl is in the midst of a comeback. Perhaps it’s due to the unpredictable whims of Millennial trends. Or, perhaps it’s the byproduct of a digital backlash from consumers...

18 Books for Better Employee Training

Books are a great way to learn new techniques to train and connect with your employees. Topics can range from practical business practices, to more subjective insights into...

Patagonia's Journey to Train Their Customers

For years, Patagonia has set a high standard for product lifespan with their Ironclad Guarantee and unparalleled customer service. They’ve been providing free repair services...

Lean Startups Need to Start Documenting to Scale

For startups that have begun to establish themselves as a sustainable business, growing pains are only a matter of time. Any experienced entrepreneur will tell you that...

How Sloppy Revision Control Cost WIPP Half a Billion Dollars

In 2014 a nuclear Waste Isolation Pilot Plant (WIPP) in Carlsbad, NM was the victim of poor revision control practices that lead to a half-billion dollar mistake; shutting...

API: Making Your Software Work For You

What is an API? For those of us outside the world of programming, the term “API” may seem like an arbitrary acronym that your IT department likes to throw around. However,...

Feature Spotlight: Prerequisite Guides

Lean Document Creation & Revision At Dozuki we view creating work instructions like any other manufacturing procedure, implementing lean principles throughout the authoring...

FDA Compliance: Why Paper-Based Documents Won't Work for Long

Modern documentation practices are becoming increasingly essential to achieving FDA compliance with the recent updates in the FDA’s approach to safety. While the importance...

Upgrading Processes with Continuous Improvement

Many companies implement formal versions of Lean or Agile methods, but others have grown with the flexibility that continuous improvement provides, giving them the freedom to...

5 Instant Benefits of Digital Work Instructions

Unlike other digital transformation projects, making the simple switch from paper-based work instructions, SOPs, and other documentation to digital work instructions provides...

Feature Spotlight: Photo Markup and Special Bullets

Here at Dozuki, we emphasize the importance of creating visual work instructions, because we believe visual is always better. However, visual documentation doesn’t stop with...

Industry 4.0 Is Here, Are You Ready?

Historically, internal systems for work instructions have been used solely for distributing procedures, with entirely separate systems for data collection and reporting....

Continuous Improvement for Writing: How Better Technical Writing Increases Efficiency

When you regard continuous improvement as a mindset, rather than just a procedural practice, you realize it has a much wider set of applications. For most of us, it’s clear...

How to Write a Great User Manual in 12 Steps

A great user manual educates people about a product, while also teaching them how to use product features effectively. As an author, your ultimate goal is comprehension—you...

What McDonald’s Can Teach Us About Training

Many years ago while managing the final inspection, packaging and shipping areas of a production plant, I was looking for a person to promote to line leader. I was having a...

The Manufacturing Dream Team

As we were plotting our celebration for 2016's Manufacturing Day, the Dozuki team got into a few squabbles about who the 'best manufacturing mind of all time' would be. (...

The True Cost of Paper-Based Documentation

Paper is viewed as a necessity in the workplace. It is used for a variety of reasons, from travel documents to field service or product manuals to employee on-boarding and...

A Quick 5 Step Guide to Lean Product Development

In the fast-paced world of product research and development, lean methodology can help reduce waste and shorten delivery times. This guide outlines five quick steps to bring...

Microsoft to Drop IE 9 & 10 Support

Microsoft has decided to drop support for their older web browsers: Internet Explorer 9 and 10. What does this mean for Dozuki clients? If you and your associates use...

Give Your Manufacturing Company a Boost

Whether you’re in aerospace or automotive, medical device or dairy—it’s important that your manufacturing company grows while keeping up with the latest innovations. In honor...

Clear Guides for Complex Procedures

Who is Improve International? Founded in 1998, Improve International recognizes that education—even for the most accomplished, professional veterinarians—doesn’t end when...

Electronic Work Instructions for Field Technicians

Who is Sterling Bank Services? Sterling Bank Services is a consultative solution, based in Montana and designed for the maintenance and security of bank equipment...

Visual Instructions for Better Communication

A technician is asked to write instructions for his company’s most frequently performed processes. Pulling out his laptop, he starts to document a procedure as he does it. He...

Dozuki is Unaffected by Heartbleed

You may have heard of the recently discovered computer security issue—“Heartbleed”—that has affected many sites across the Internet. Rest assured, Dozuki has not been...